A nickel-doped barium polytitanate yellow solar heat reflective pigment

A technology of polybarium titanate and reflective pigments, which is applied in the direction of reflective/signal coatings, etc., can solve the problems of limited application range, and achieve the effect of excellent color performance and high near-infrared reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] And specifically in this embodiment, the method for processing nickel-doped barium polytitanate yellow solar heat reflective pigment using solid-phase method, the specific processing steps are as follows:

[0035] Step 1, take 7.6 grams of titanium dioxide, 3.94 grams of barium carbonate and 0.375 grams of nickel oxide, ball mill and mix evenly;

[0036] Step 2, calcining at 1000 ℃ for 4 hours, then cooling, and finally grinding, that is, 5% Ni doped BaTi 5 O 11 yellow pigment;

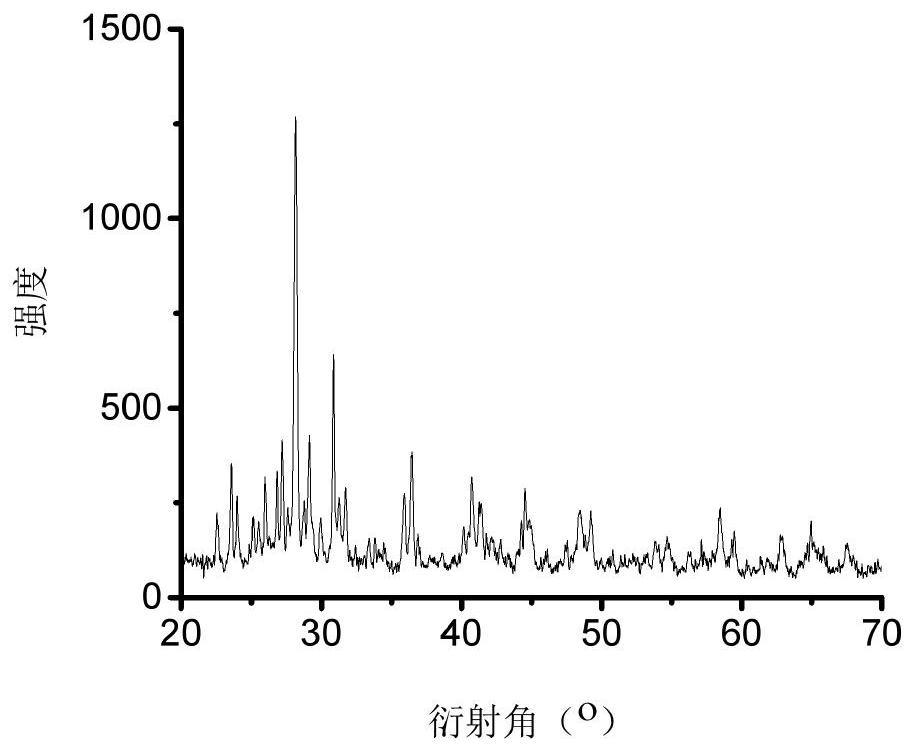

[0037] figure 1 The XRD pattern of the pigment prepared in this example, the phase of the pigment is BaTi 5 O 11 ;

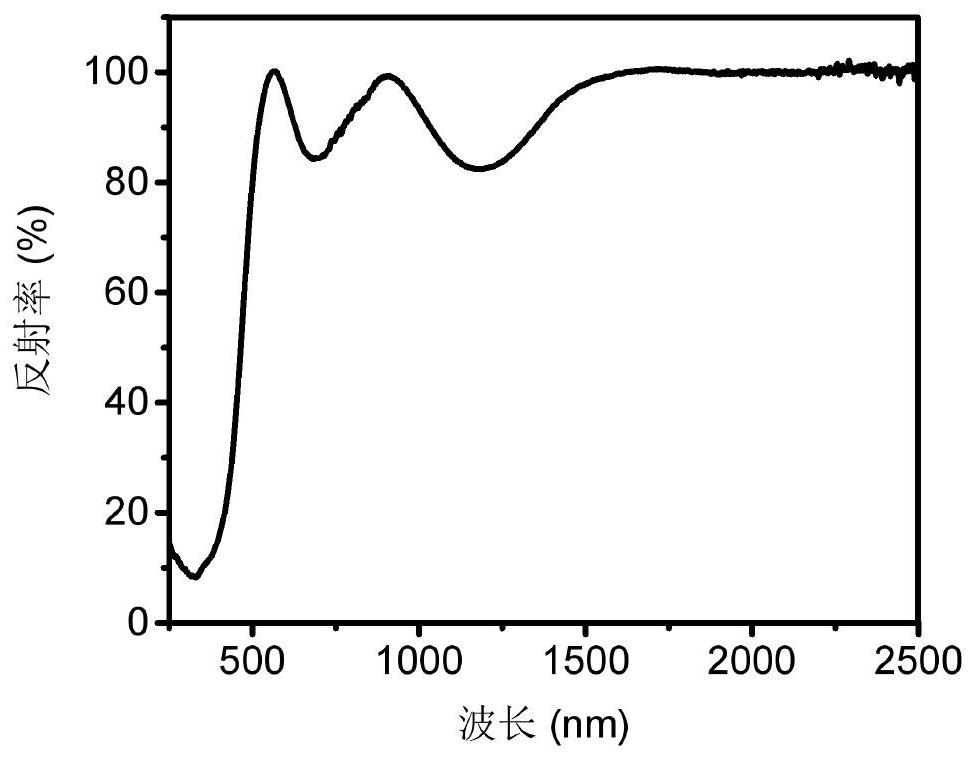

[0038] image 3 For the UV-Vis-NIR reflectance map of this pigment, the sample has a strong reflectivity in the range of 500-2500nm, indicating that it can be used as a solar heat-reflecting pigment;

[0039] Disperse the sample into PU and apply a film on the surface of the brick. After being illuminated by an infrared lamp for 30 minutes, the temperature of the back of t...

Embodiment 2

[0042] Different from above-mentioned implementation: 1, in the present embodiment, the method for processing nickel-doped barium polytitanate yellow solar heat reflective pigment using solid-phase method, and the concrete processing steps are as follows:

[0043] Step 1. Take 7.2 grams of titanium dioxide, 3.07 grams of barium oxide and 0.927 grams of nickel hydroxide, and mix them evenly by ball milling;

[0044] Step 2, calcining at 1100 °C for 2 hours, then cooling, and finally grinding, that is, 10% Ni-doped BaTi 5 O 11 Yellow paint.

[0045] The color properties of the obtained pigments are shown in Table 1.

Embodiment 3

[0047] Different from the above-mentioned embodiment 1-2, in this embodiment, the method for processing nickel-doped barium polytitanate yellow solar heat reflective pigment by solid-phase method is used, and the specific processing steps are as follows:

[0048] Step 1, take 7.6 grams of titanium dioxide, 4.3 grams of barium hydroxide and 0.594 grams of nickel carbonate, ball mill and mix uniformly;

[0049] Step 2, calcining at 1000 ℃ for 4 hours, then cooling, and finally grinding, that is, 5% Ni doped Ba 2 Ti 9 O 20 Yellow paint.

[0050] The color properties of the obtained pigments are shown in Table 1.

[0051] Liquid-Solid Phase Method Example

[0052] A nickel-doped barium polytitanate yellow solar heat reflective pigment, the phase used is BaTi 5 O 11 , BaTi 4 O 9 or Ba 2 Ti 9 O 20 one or more blends of;

[0053] A method for processing nickel-doped barium polytitanate yellow solar heat reflective pigment using a liquid phase-solid phase combination method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com