Continuous ultrasonic emulsification device for water-based resin and using method of continuous ultrasonic emulsification device

A technology of ultrasonic emulsification and water-based resin, applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problems of too large diameter of latex particles, inability to shear resin prepolymers, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

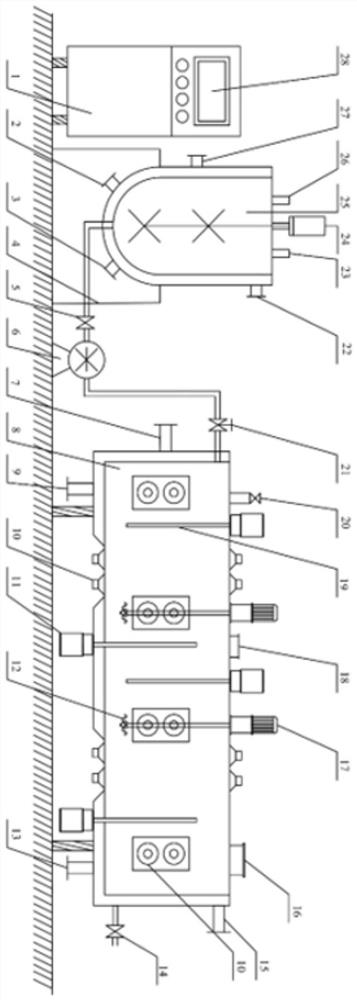

[0025] Such as figure 1 As shown, the main train of thought of the present invention is to adopt the instantaneous method in pipeline type ultrasonic emulsification treatment, a kind of water-based resin continuous type ultrasonic emulsification device provided, specifically comprises:

[0026] The premixing chamber 25 and the emulsification chamber 8 connected together by pipelines are provided with a first feeding port 23 and a second feeding port 26, so that the continuous phase and the dispersed phase are separately added into the premixing chamber 25, Thereby controlling the mixing ratio of the continuous phase and the dispersed phase, the outer walls of the premixing chamber 25 and the emulsification chamber 8 are provided with jackets, the bottom of the jackets are provided with cooling water inlets and condensed water outlets, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com