Patents

Literature

82results about How to "Reasonably arranged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

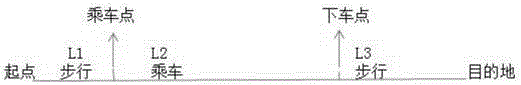

Intelligent trip method and system

InactiveCN105973249AAccurate travel forecastImprove wake-up effectInstruments for road network navigationTravel modeTime information

The invention provides an intelligent trip method and system, wherein the method includes the steps: obtaining location information of a starting point and a destination, and carrying out route planning, to obtain a trip route and a trip mode; according to the location information of the starting point and the destination, calculating the distance between the starting point and the destination; obtaining the expected arrival time information and date; obtaining public transport means data information; according to the distance between the starting point and the destination, the public transport means data information, the time information and the date, calculating specific driving time; according to the expected arrival time and the specific driving time, calculating actual bell ringing time; and setting the bell ringing time of an alarm clock. Due to the adoption of the alarm clock, a user can set the alarm clock for reminding the user to start in advance according to user needs.

Owner:SHENZHEN TINNO WIRELESS TECH

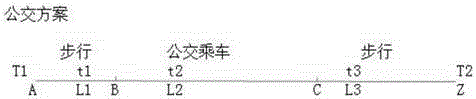

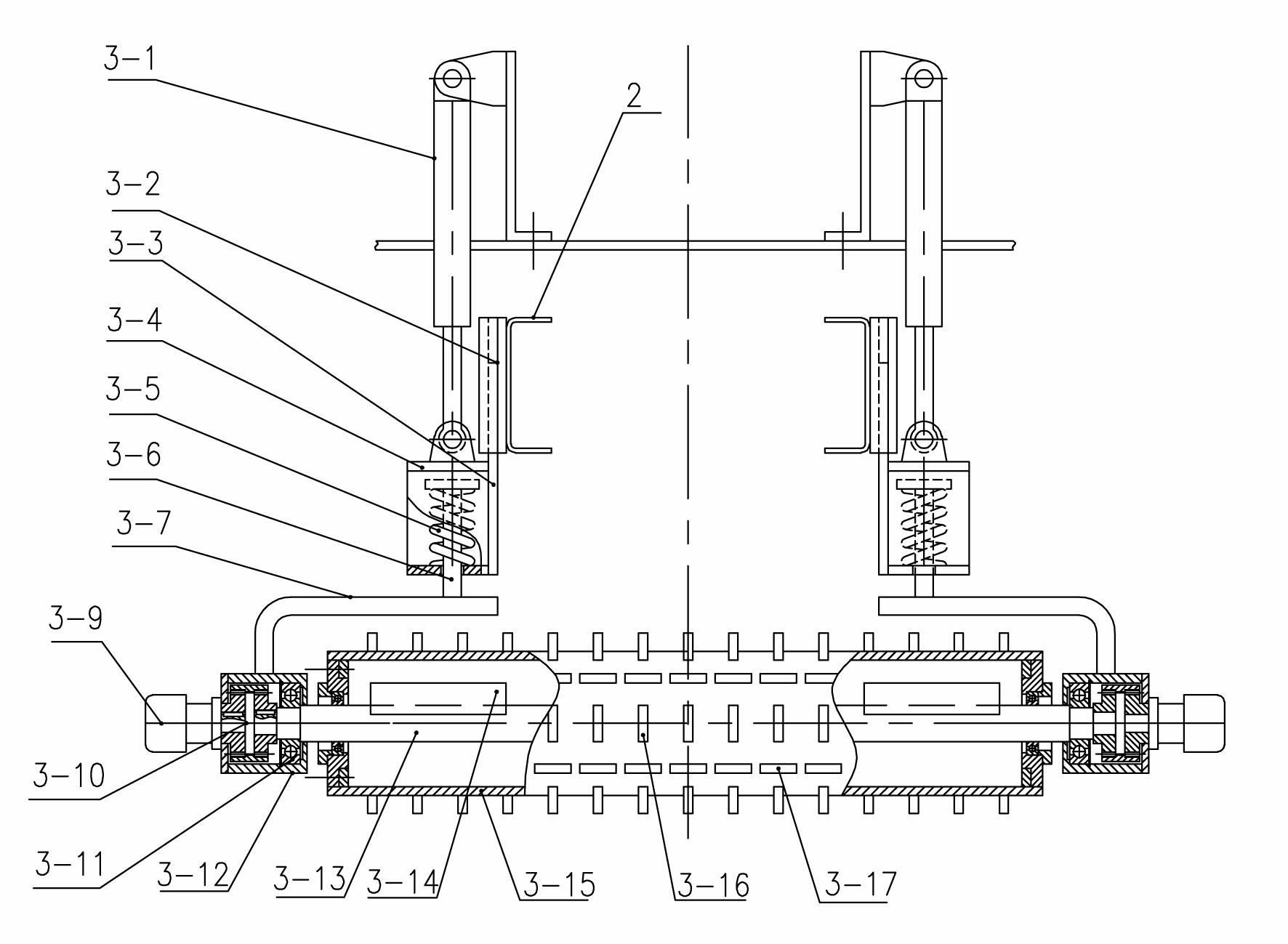

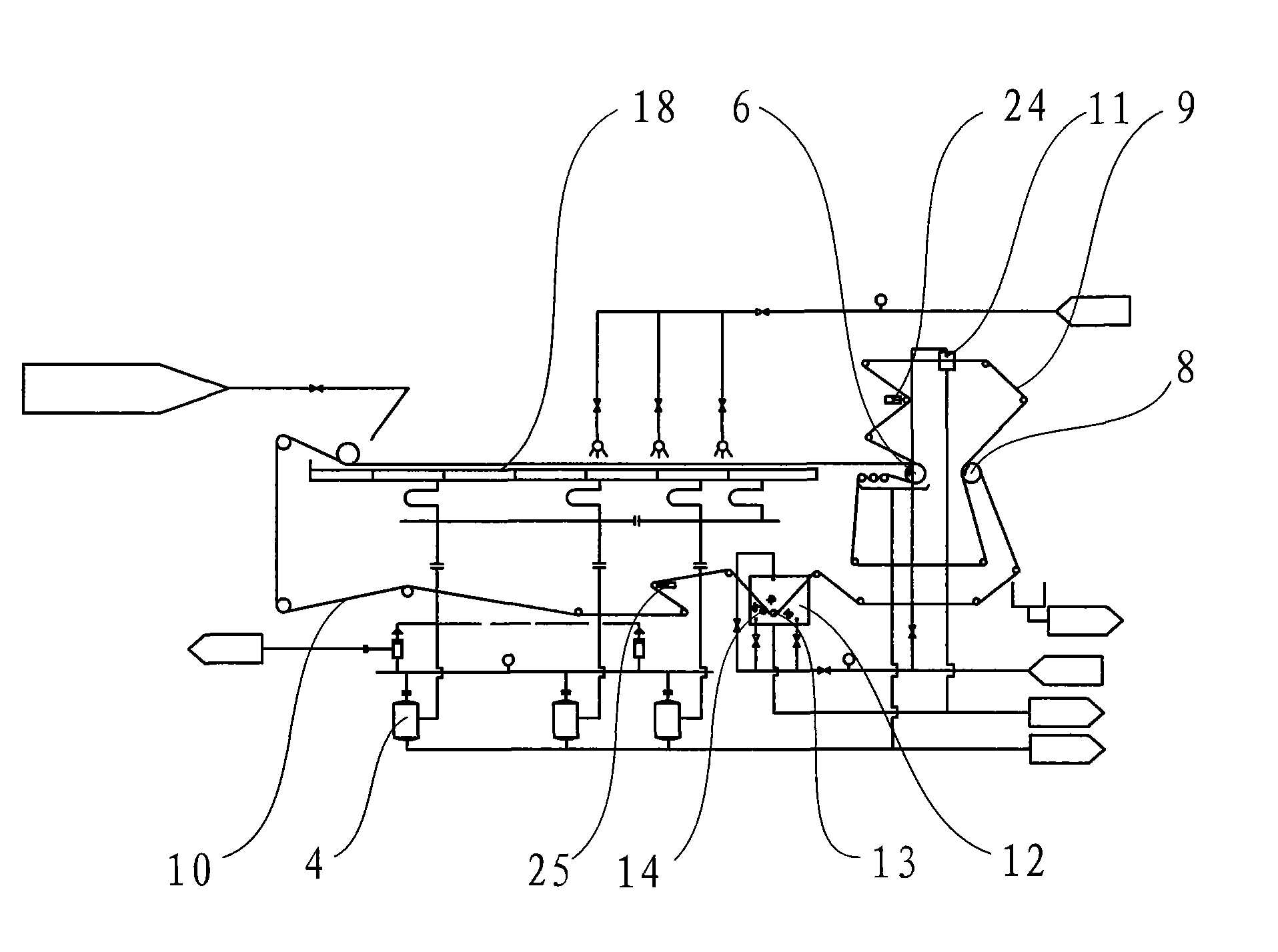

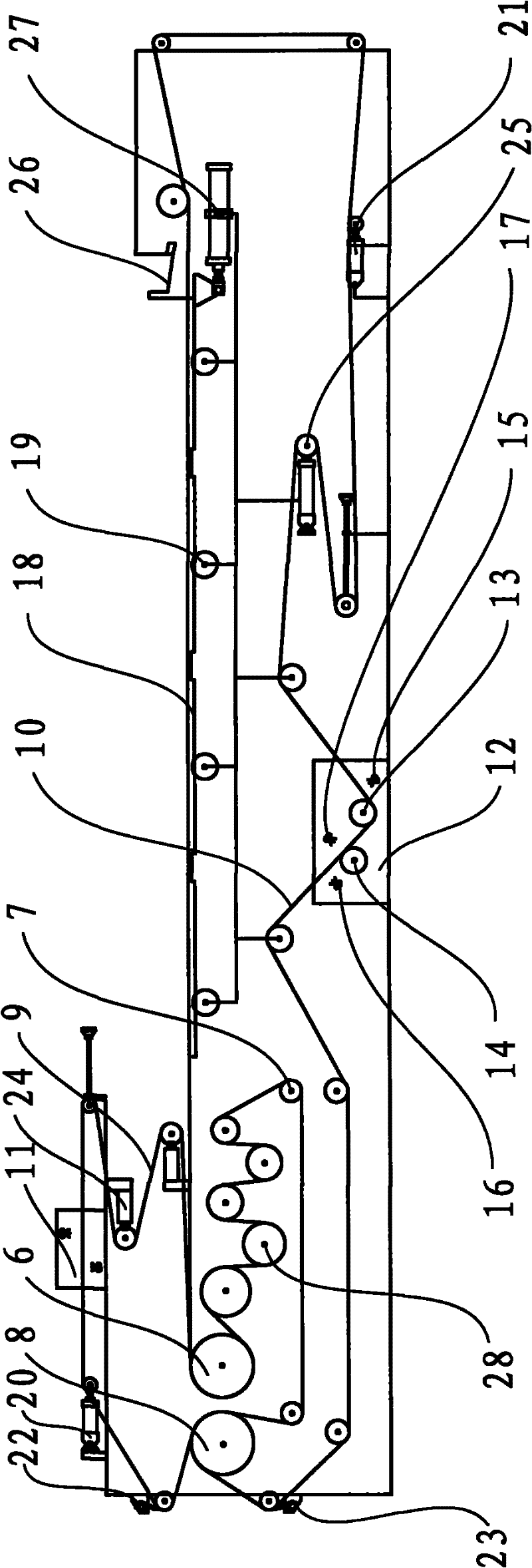

Vehicle-mounted multifunctional snow remover

ActiveCN102094401AImprove snow removal qualityFast snow removalSnow cleaningHydraulic motorSnow removal

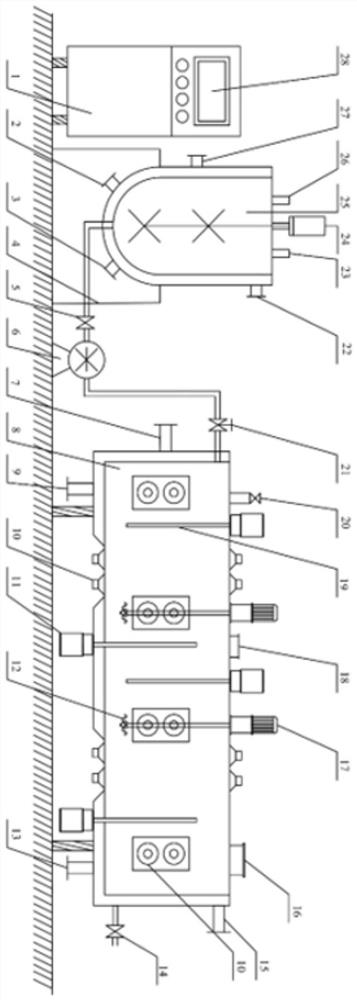

The invention belongs to the technical field of snow removal equipment for removing snow on a road and spreading a snow-melting agent, and in particular to a vehicle-mounted multifunctional snow remover. The vehicle-mounted multifunctional snow remover comprises a vehicle cab, a snow removal shovel device, a vehicle chassis, a hydraulic pump station, a snow-melting agent spreader and a swing ventral shovel device, wherein, the swing ventral shovel device is arranged in the middle part of the vehicle chassis; an ice-breaking roller device is arranged in the front of the swing ventral shovel device, and a snow-sweeping roller brush device is arranged in the back of the swing ventral shovel device; the ice-breaking roller device consists of an ice-breaking roller chute, an ice-breaking roller slide rail, a spring seat, a spring bar, a spring, an ice-breaking roller and an ice-breaking roller lift cylinder; and the snow-sweeping roller brush device consists of a roller brush chute, a roller brush slide rail, a support plate, a support axle, a worm wheel, a roller brush frame, a roller brush assembly, a worm, a roller brush rotating-angle adjustment hydraulic motor and a roller brush lift cylinder. The vehicle-mounted multifunctional snow remover has the advantages of completing the four procedures of pushing snow, breaking ice, sweeping and spreading the snow-melting agent once, improving the snow removal effect, accelerating the snow removal speed and protecting the original asphalt pavement from damage.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

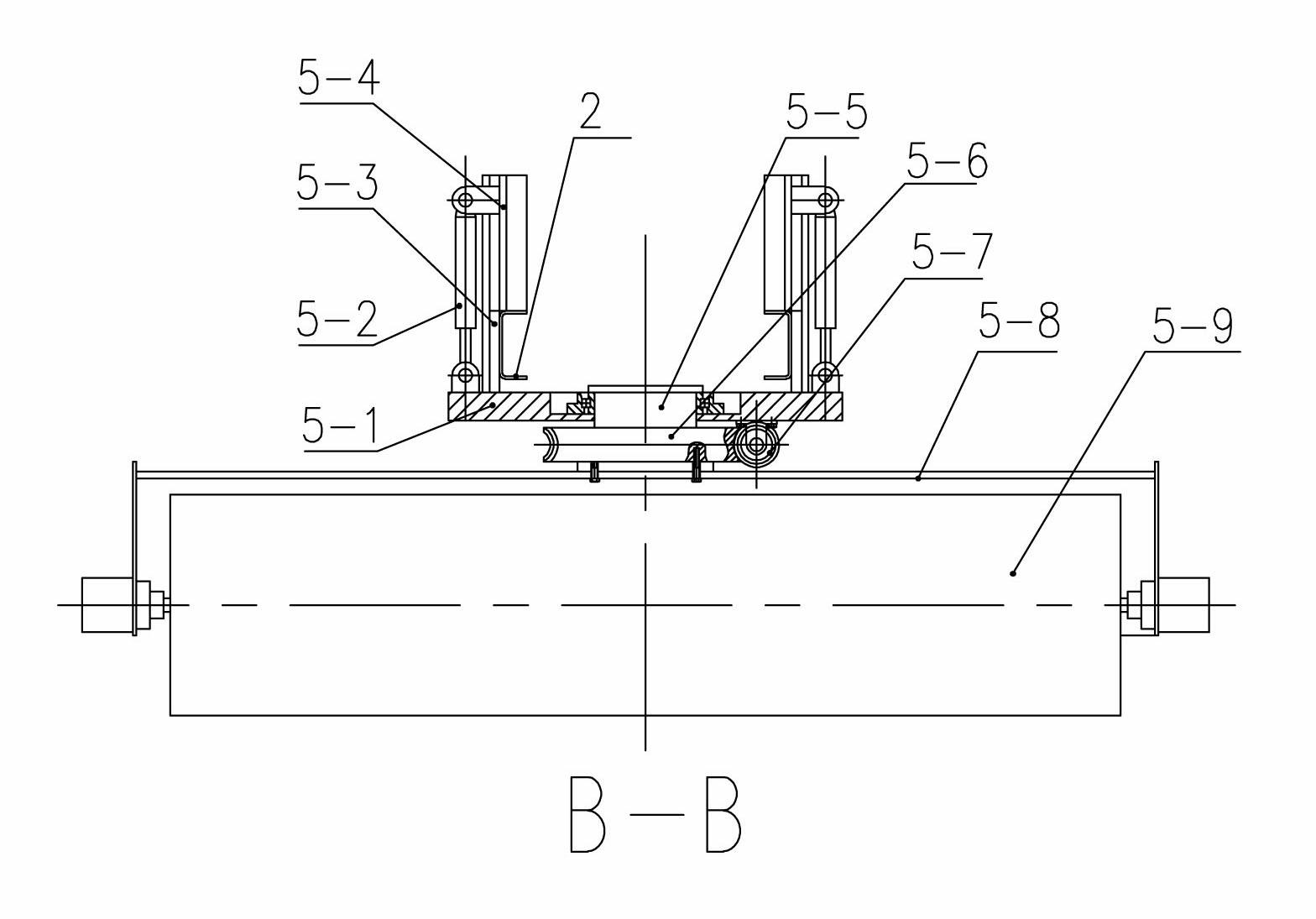

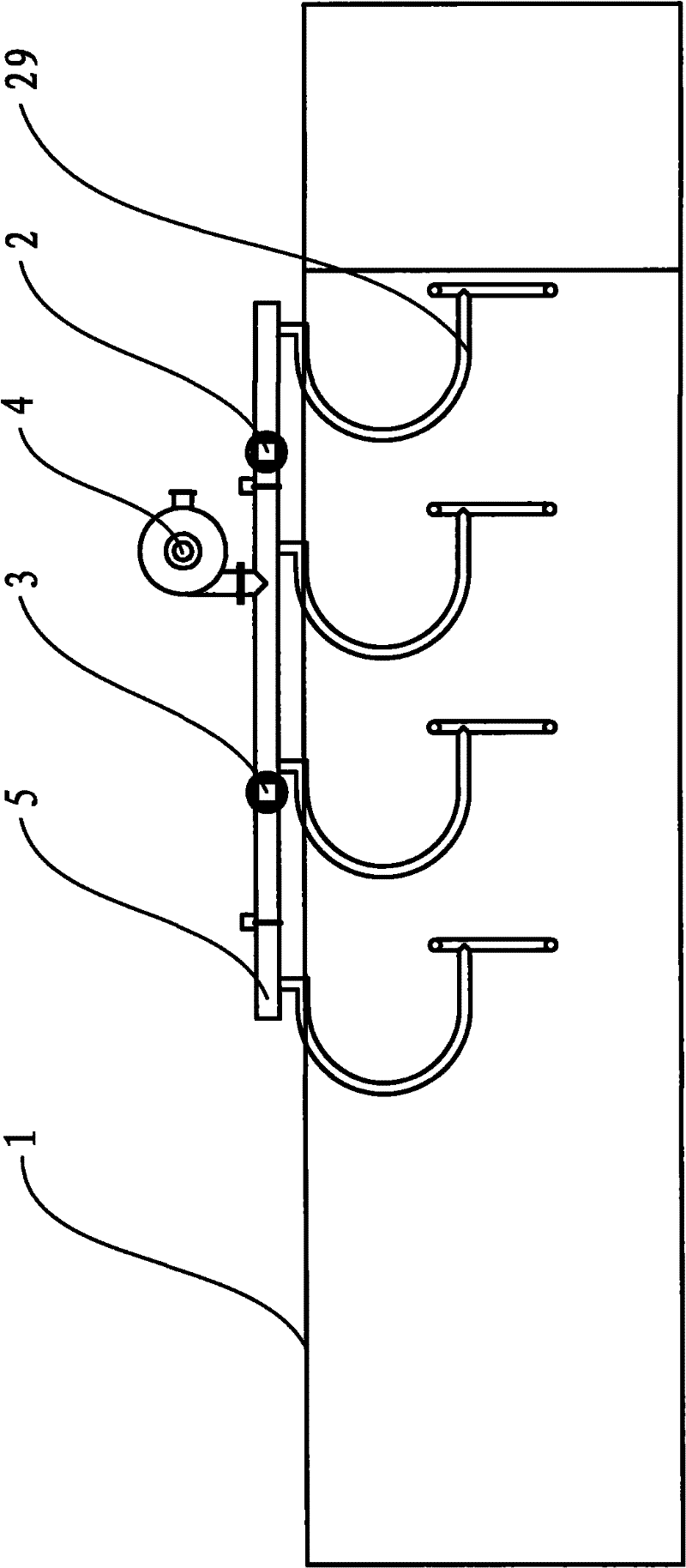

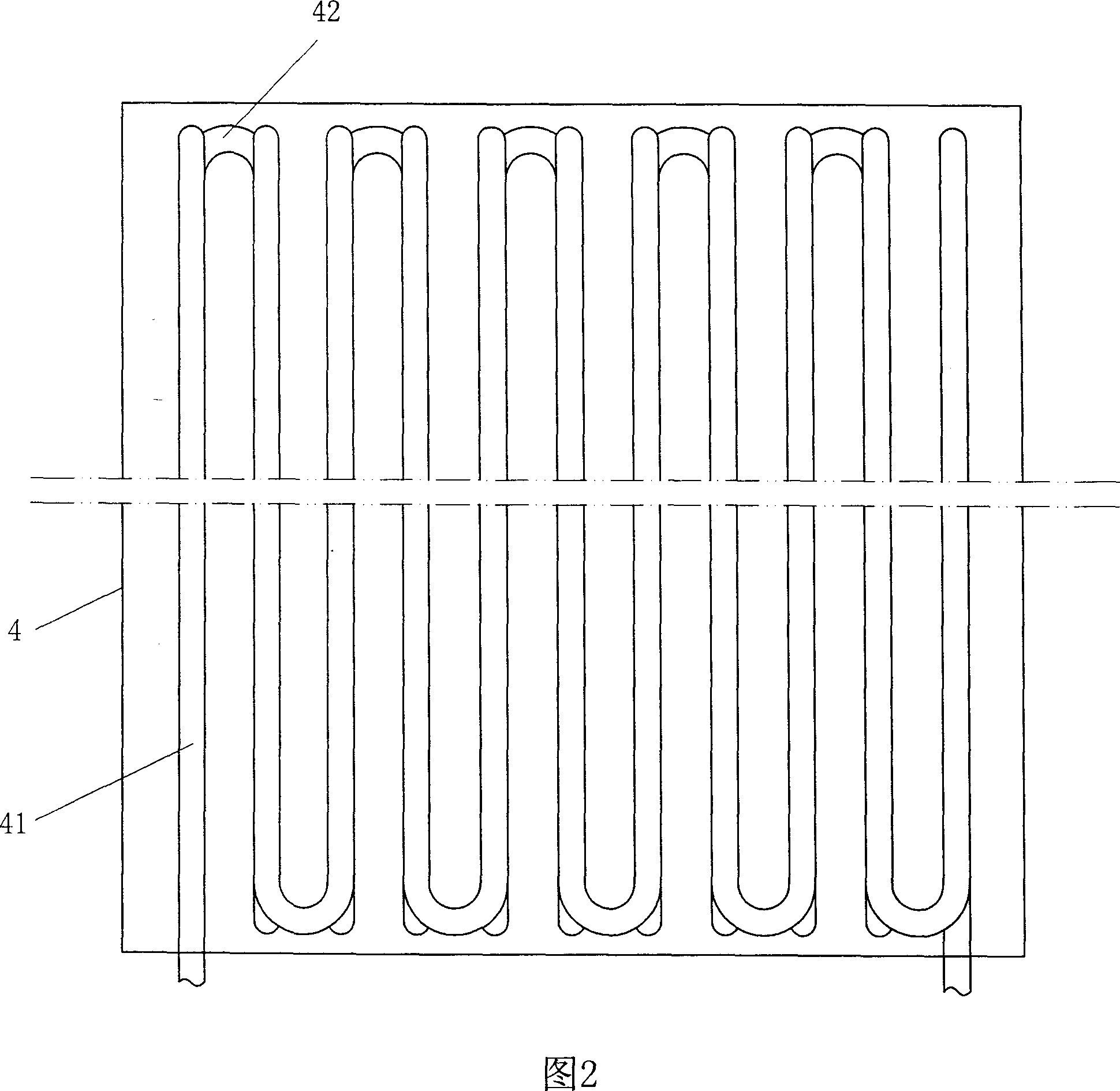

Vacuum belt press filter

InactiveCN101612805AEasy to cleanRealize automatic continuous operationCleaning using liquidsPressesFiltrationPulp and paper industry

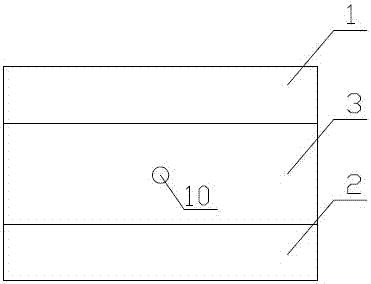

The invention relates to a vacuum belt press filter, comprising a rack, a vacuum filtration assembly, a press assembly and a filtration belt assembly, wherein the filtration belt assembly comprises an upper filtration belt, a lower filtration belt, and a cleaning device A and a cleaning device B which are used for respectively cleaning the upper filtration belt and the lower filtration belt; the cleaning device B comprises a front guide roller and a rear guide roller on the motion direction of the lower filtration belt, the front guide roller is arranged on the upper face the lower filtration belt, closely contacts the lower filtration belt and enables the lower filtration belt to form a V shape, the rear guide roller is arranged on the lower face of the lower filtration belt and is provided with a plurality of pinpricks, the size of each pinprick is matched with the size of a filtration pore of the filtration belt, and the rear guide roller contacts with the lower filtration belt by the pinpricks; and the cleaning device B is provided with a plurality of spray heads, and the spray heads are distributed on the upper face and the lower face of the lower filtration belt. The vacuum belt press filter of the invention has the advantage of favorable cleaning effect of the filtration belts, and belongs to the technical field of press machines.

Owner:HUZHOU HEHONG MACHINERY

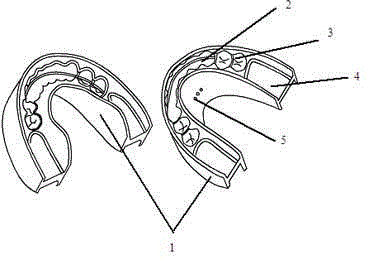

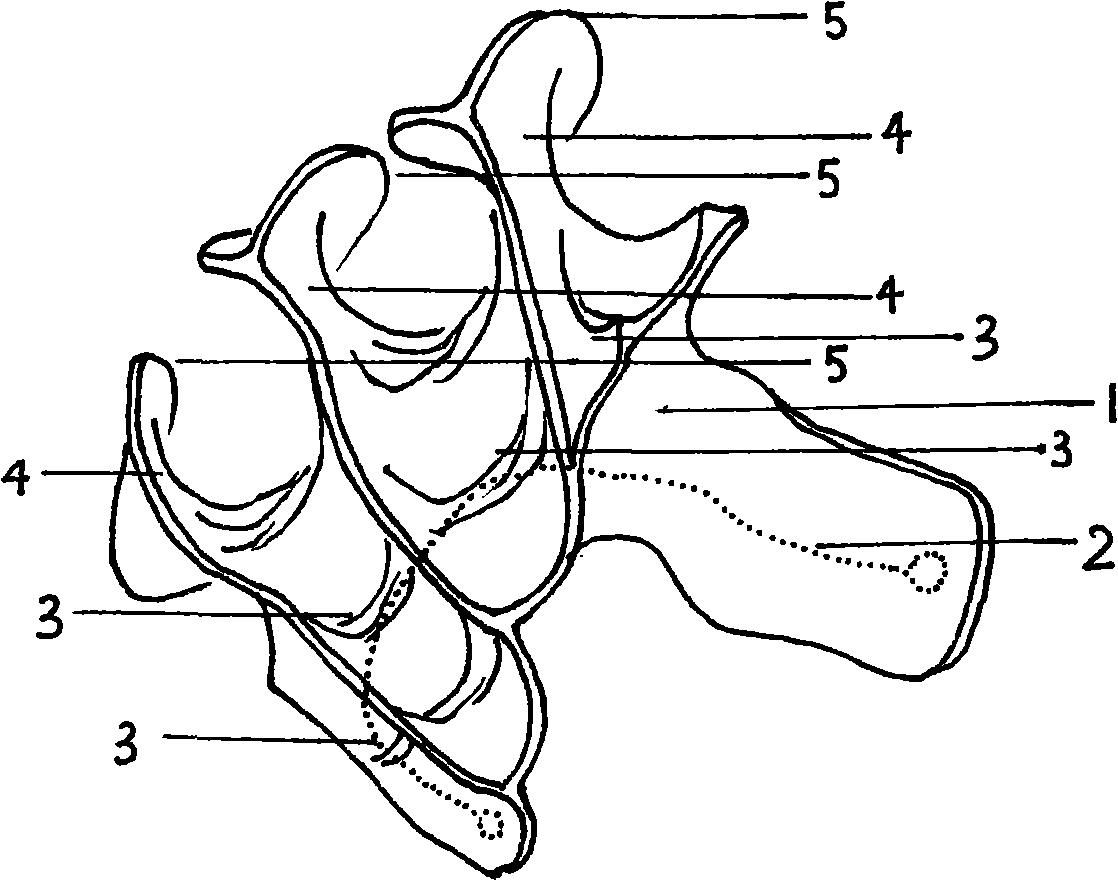

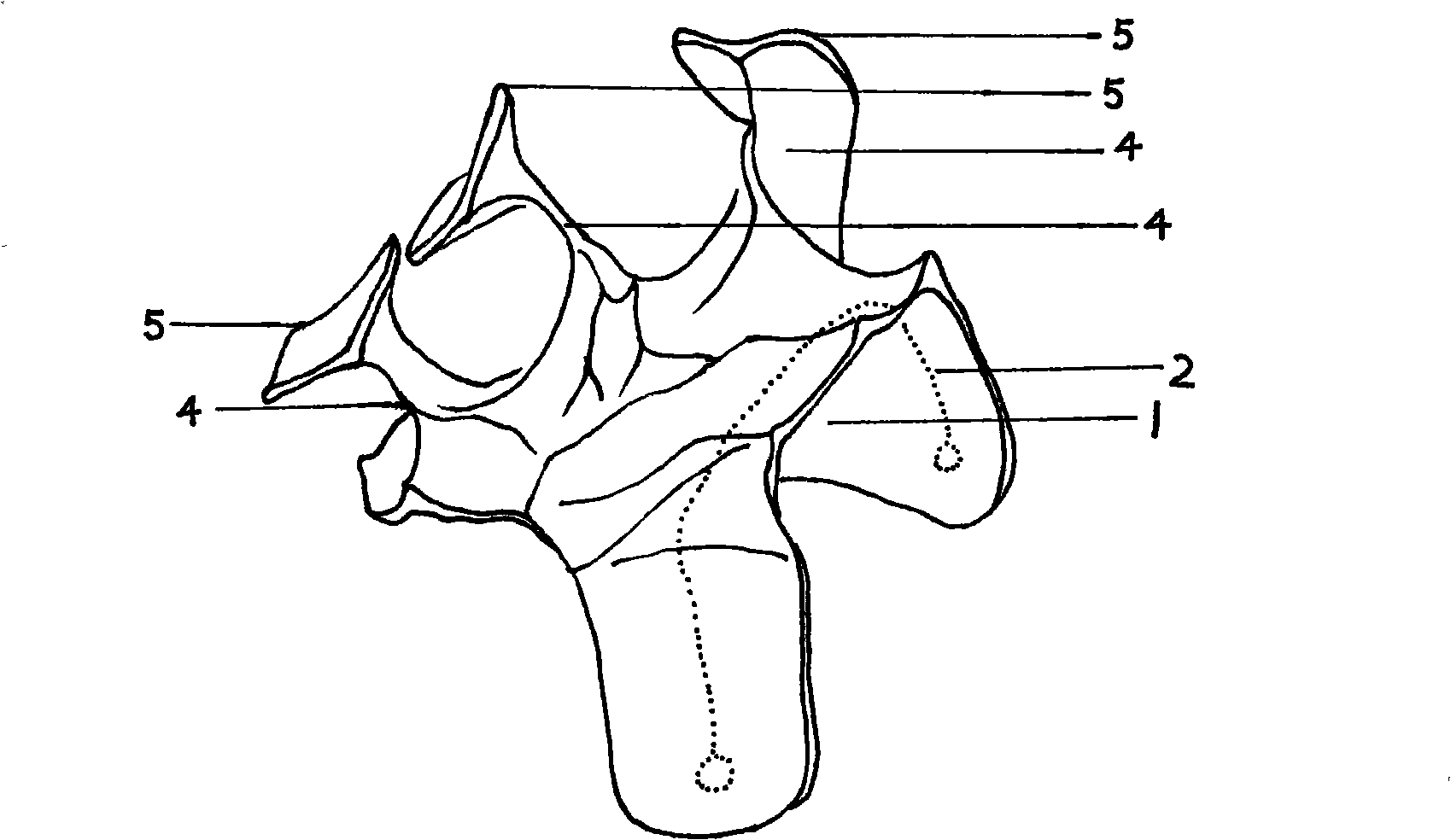

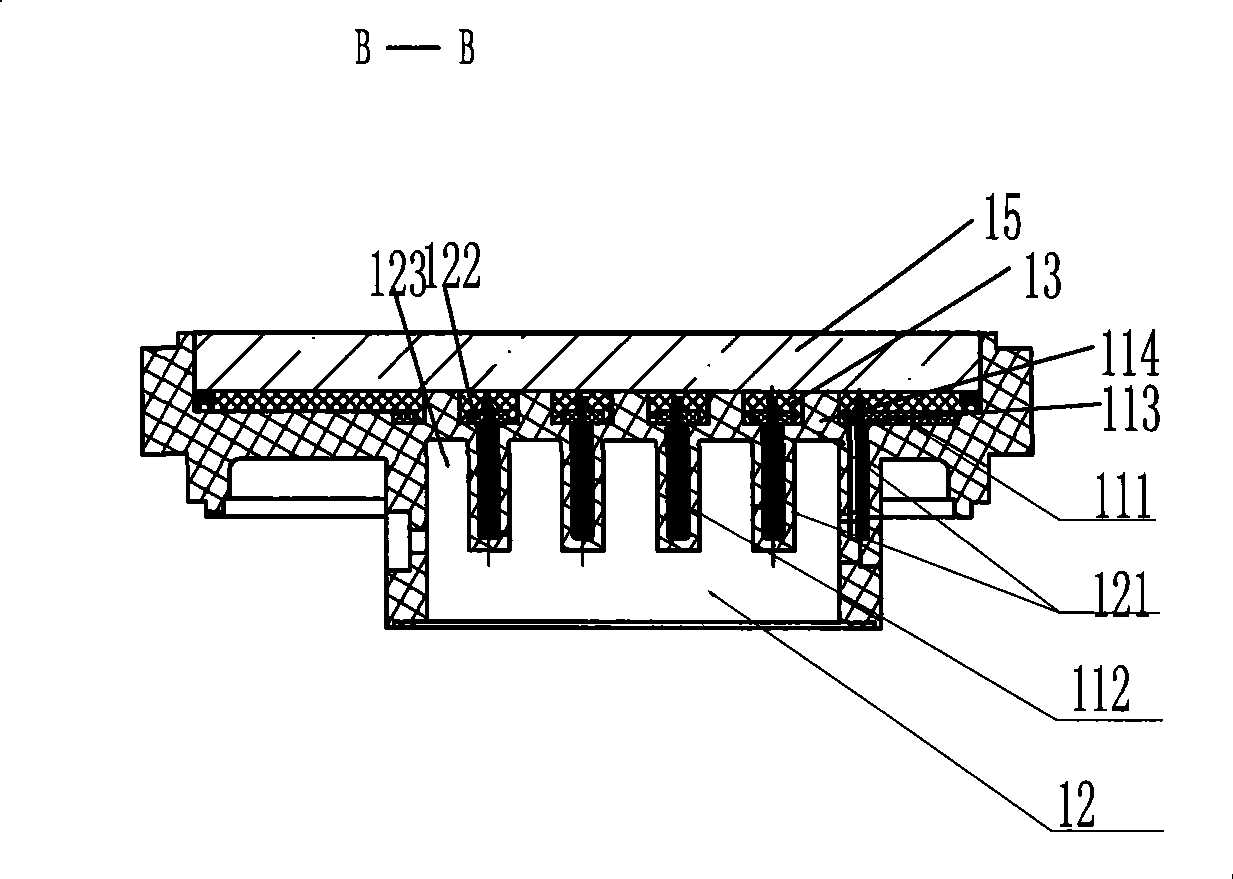

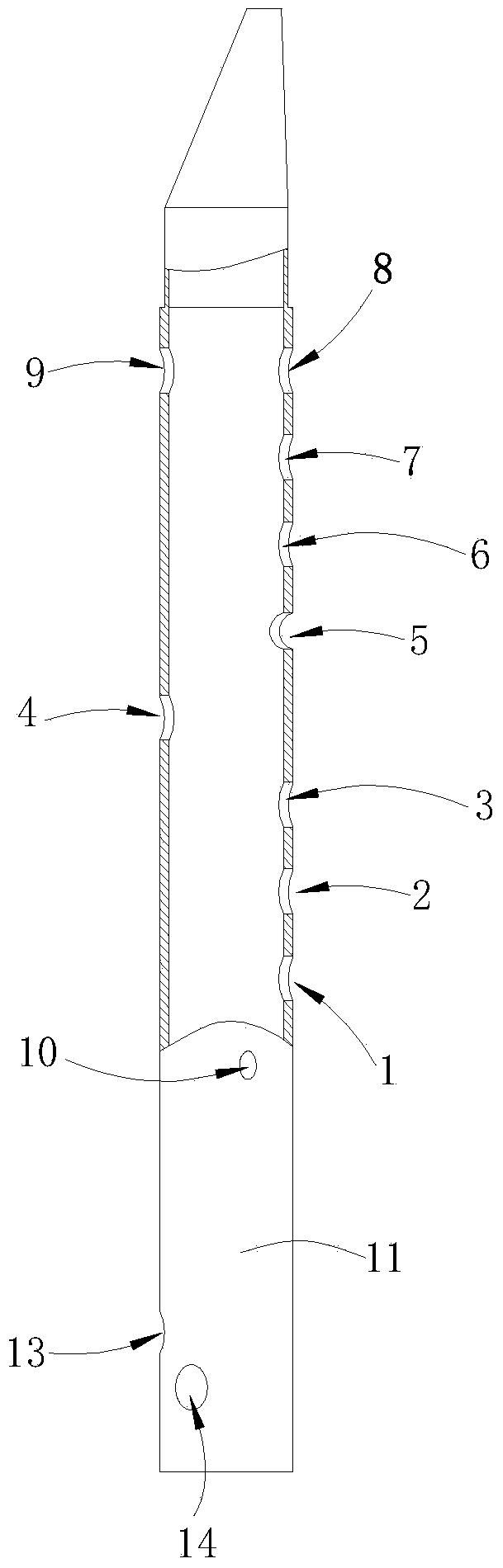

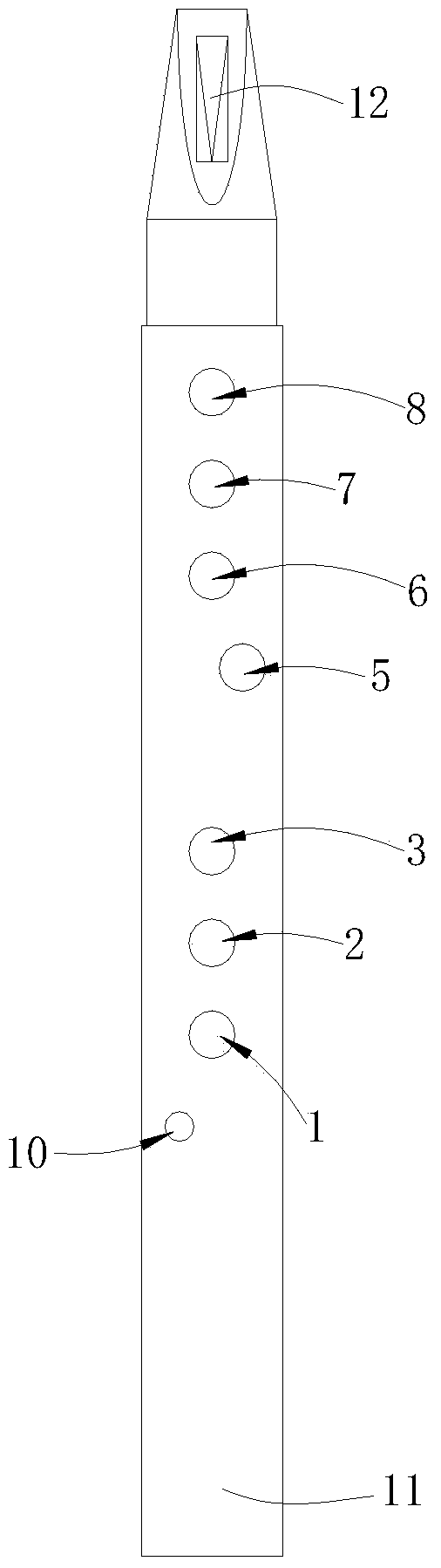

Device for inducing reasonable arrangement of teeth of children and manufacturing method of device

The invention relates to a device for inducing reasonable arrangement of teeth of children and a manufacturing method of the device. Based on a three-dimensional model of a standard upper jaw and a standard lower jaw in a standard occlusal relation and a tooth socket in a dental arch track and form design, the device comprises upper and lower notches, side wall flanges at lip sides and tongue sides and breathing holes, wherein the shapes, the sizes and the spatial arrangement position of the upper and lower notches are designed according to standard tooth jaws; the upper and lower notches are different from teeth to be induced so that the notches generate a certain induction force for the teeth to be induced to induce the teeth to be reasonably arranged in the target direction; and the side wall flanges at the lip sides and the tongue sides are designed according to gums and mucosae of the standard upper jaw and the standard lower jaw in the standard occlusal relation, the oral and perioral soft tissue forms are adjusted so as to achieve the final effect of teeth induction. According to the dental arch line track of a patient, an appropriate tooth socket is selected, the manufacturing cost is reduced, the efficiency is improved, the financial burden is reduced for the patient and meanwhile the purpose of inducing reasonable arrangement of the teeth of the children is achieved.

Owner:何炳蔚 +1

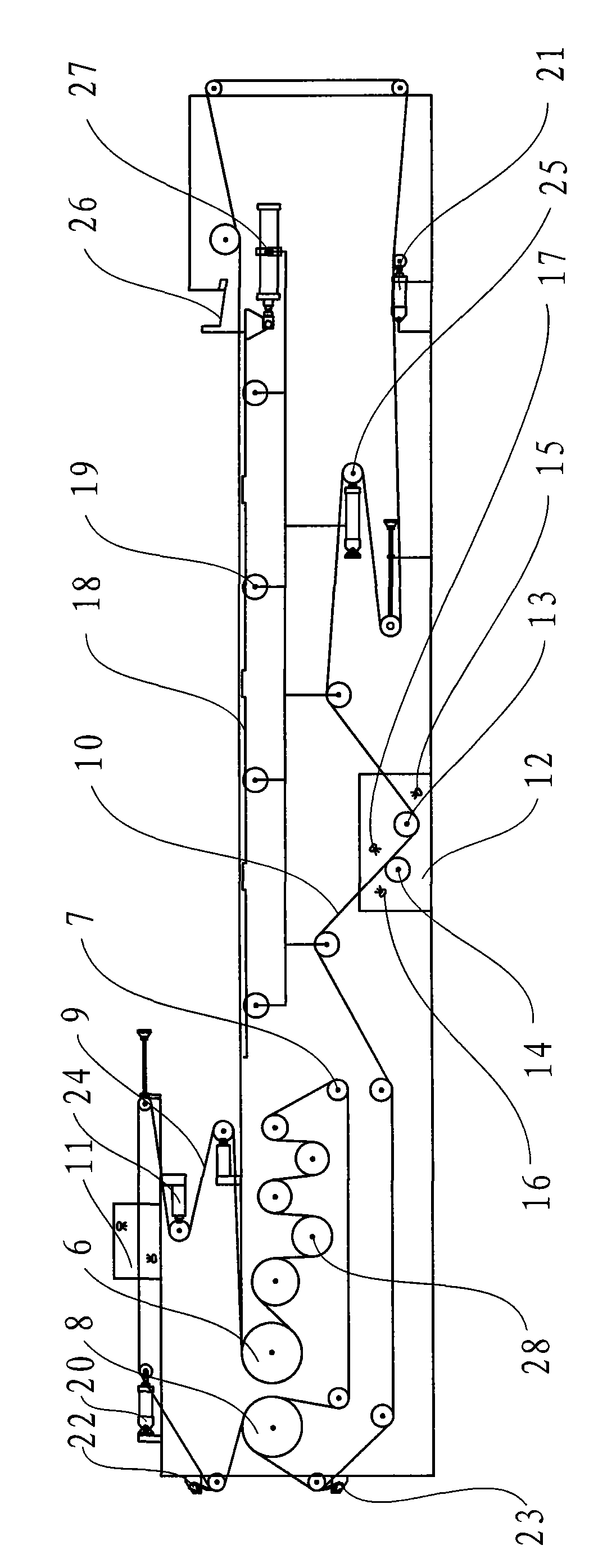

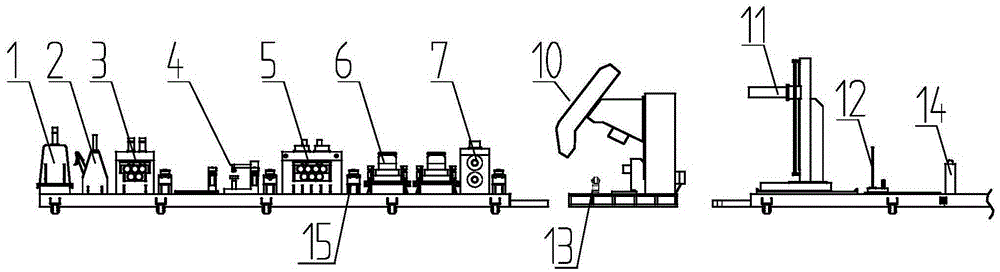

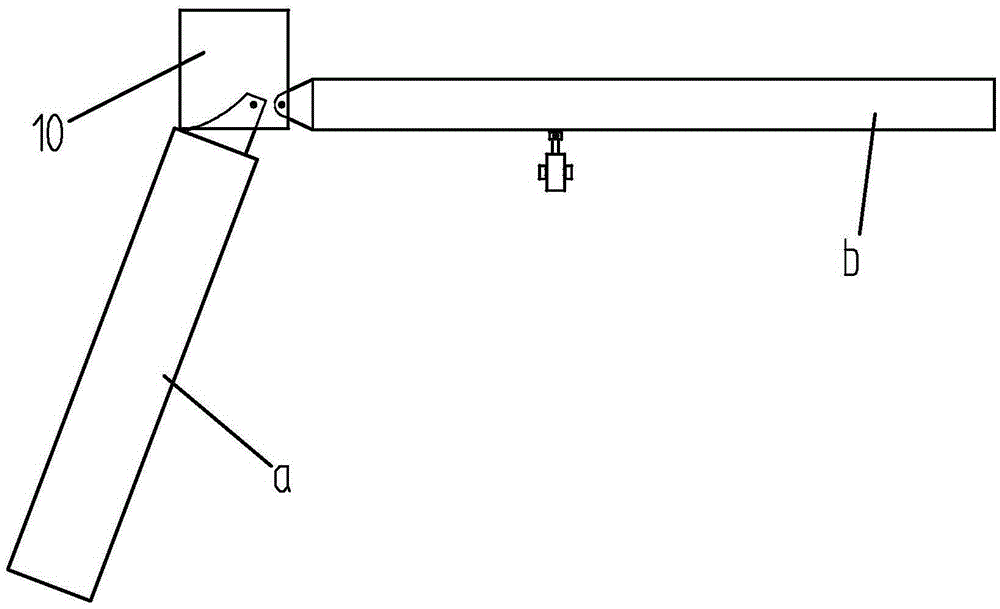

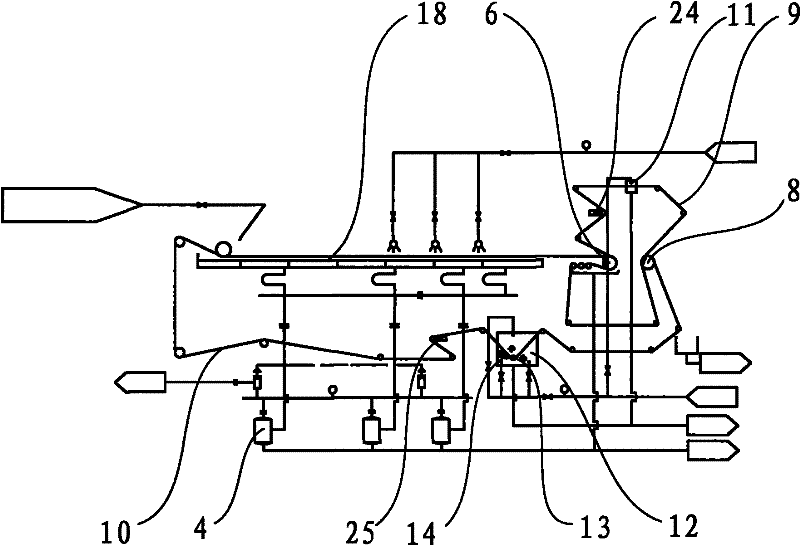

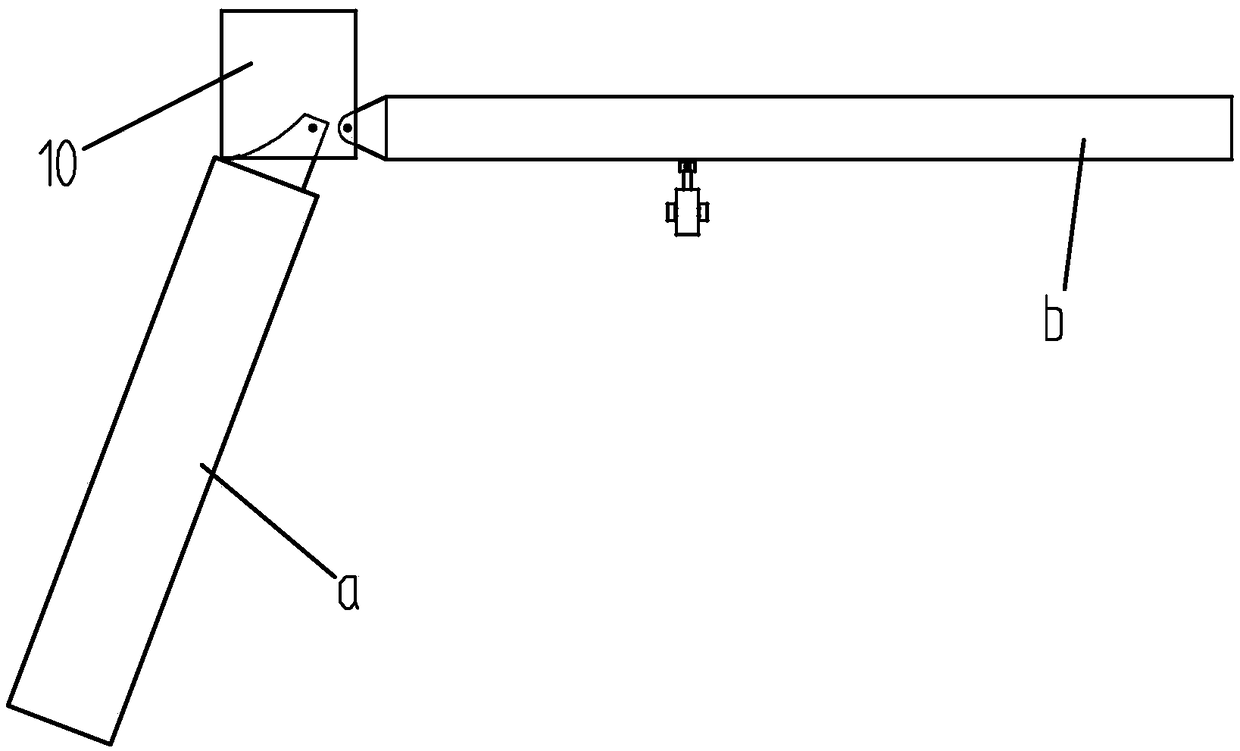

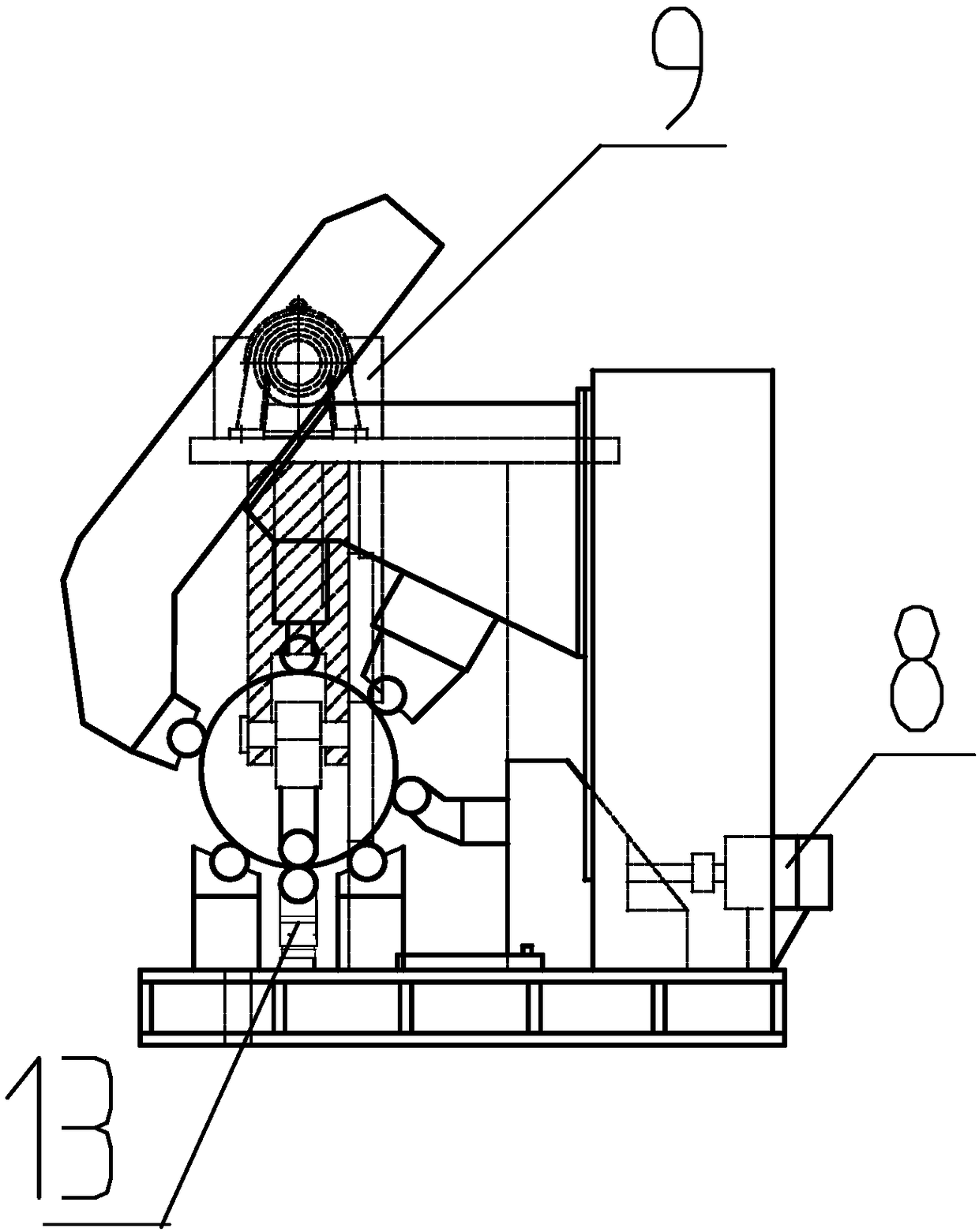

Novel spiral pipe production line

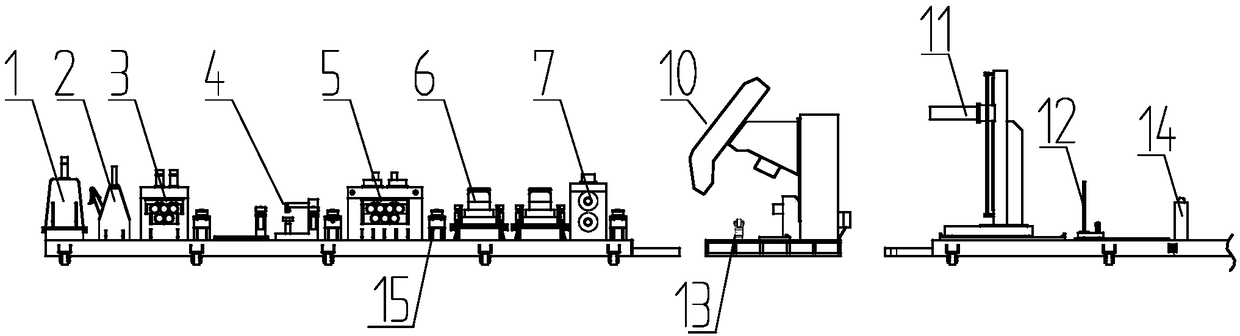

The invention provides a novel spiral pipe production line and belongs to the field of production of spiral pipes. The production line comprises a decoiling device, a shovel head device, a rough leveling device, a fast butt joint device, a fine leveling device, an edge milling device, a traction device, a centering device, a cutting device and a rear axle carrier roller. A molding device comprises a bottom plate, a molding frame, a first roller beam, a second roller beam, a third roller beam, a fourth roller beam, a fifth roller beam, a sixth roller beam, a seventh roller beam and a welding pad roller. A work area used for making steel pipes is reserved in the center of the molding frame. The seven roller beams are arranged in the work area of the molding frame. An included angle is formed between every two roller beams, and the roller beams are spirally arranged. An automatic roller beam vertical sliding device and an automatic roller beam horizontal moving device are further arranged on the bottom plate. The automatic roller beam vertical sliding device is connected with the roller beam right opposite to the welding pad roller. The automatic roller beam horizontal moving device is connected with the roller beam located on the center horizontal plane of the work area. According to the novel spiral pipe production line, the structure of the production line is greatly adjusted, arrangement of the devices is more reasonable, and the yield is higher.

Owner:河北德威钢管有限公司

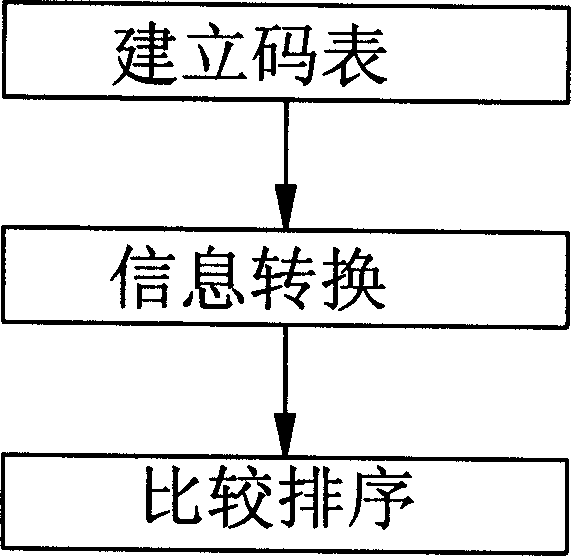

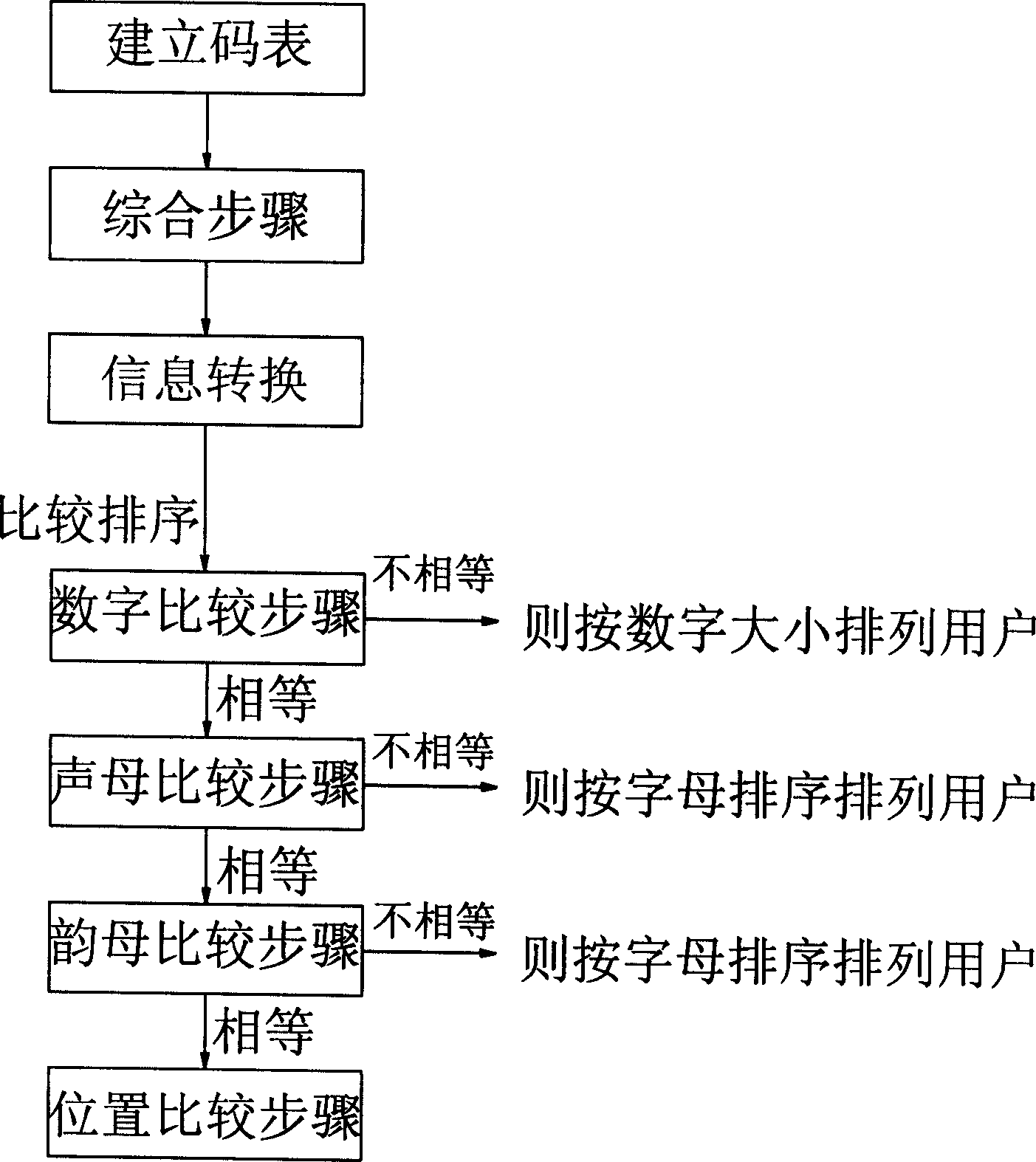

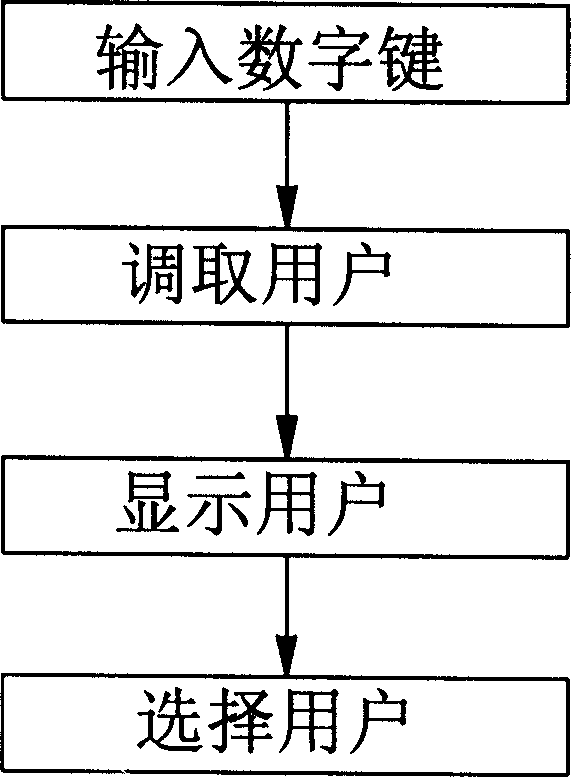

Method for sorting and looking up telephone book of hand held

ActiveCN1728735AReasonably arrangedFind intuitiveSubscriber signalling identity devicesSpecial data processing applicationsTelecommunicationsHand held

The method includes steps: first, building code table; then, information conversion; finally, carrying out comparison sort. Being converted to corresponding number, memory code of name (Unicode) of each user is arranged on phone book according to big and small. Keyboard of number converted from memory code of name (Unicode) is the keyboard the Unicode located at. Method for looking-up phone book of hand held device includes steps: first inputting number key; second, calling and obtaining user; third displaying user, finally, selecting user. Features are: convenience for looking up phone book, and quick.

Owner:AMOI TECH

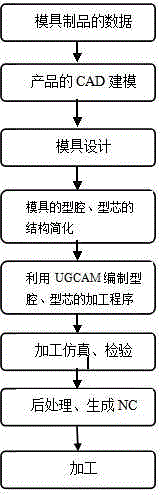

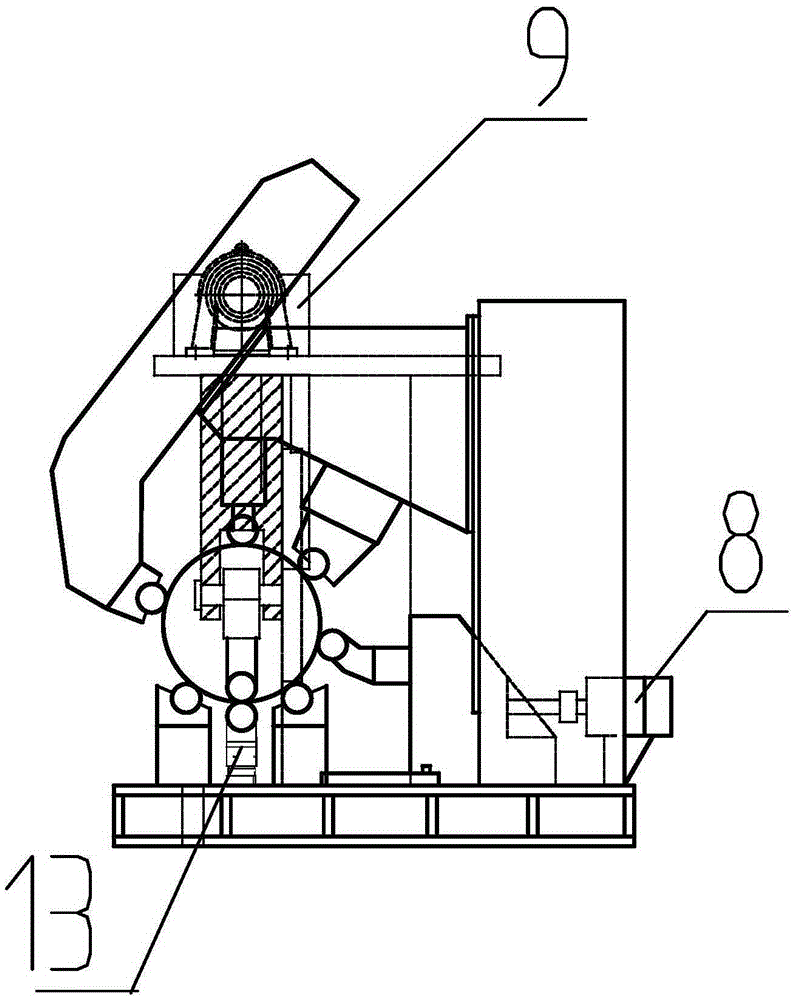

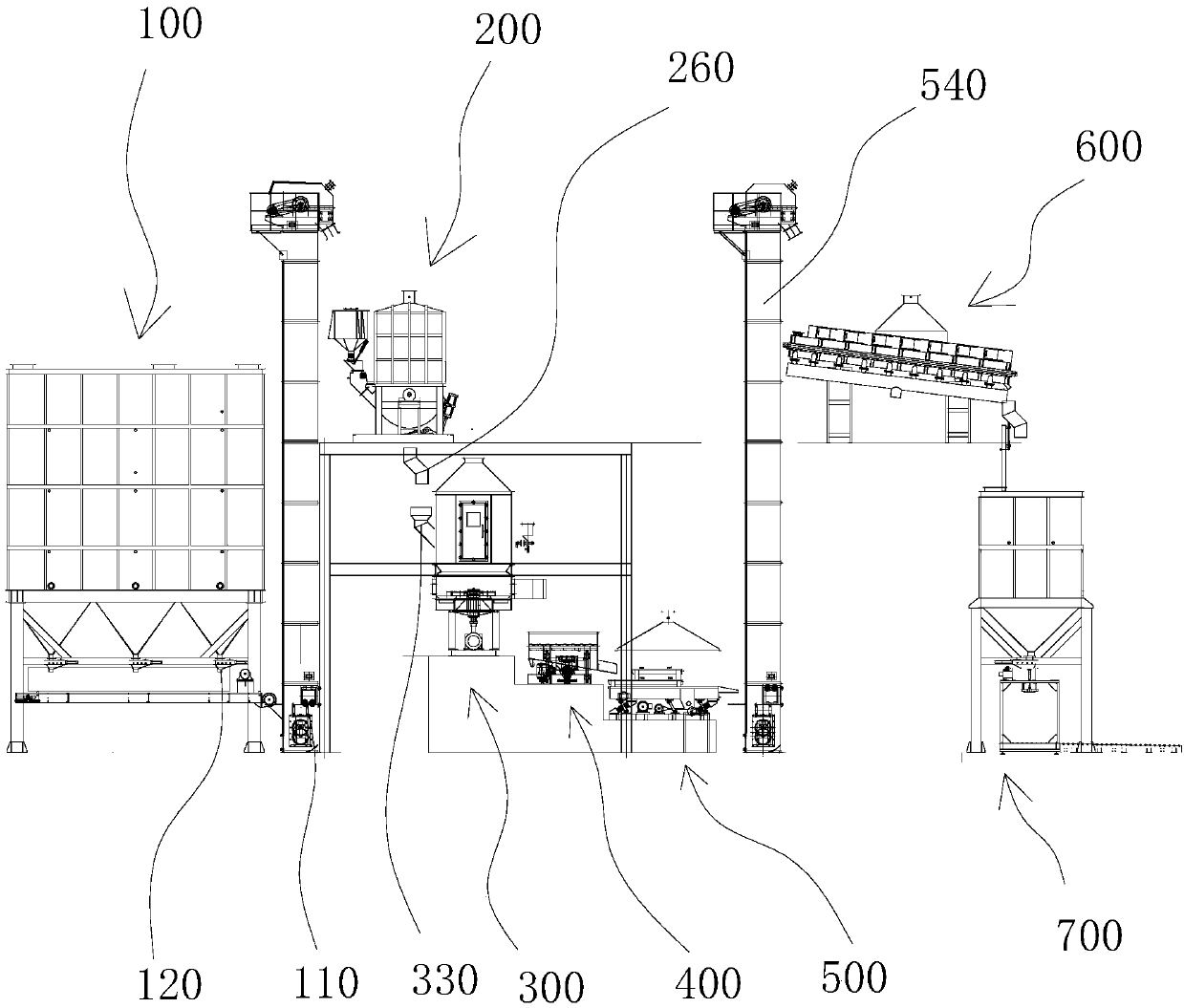

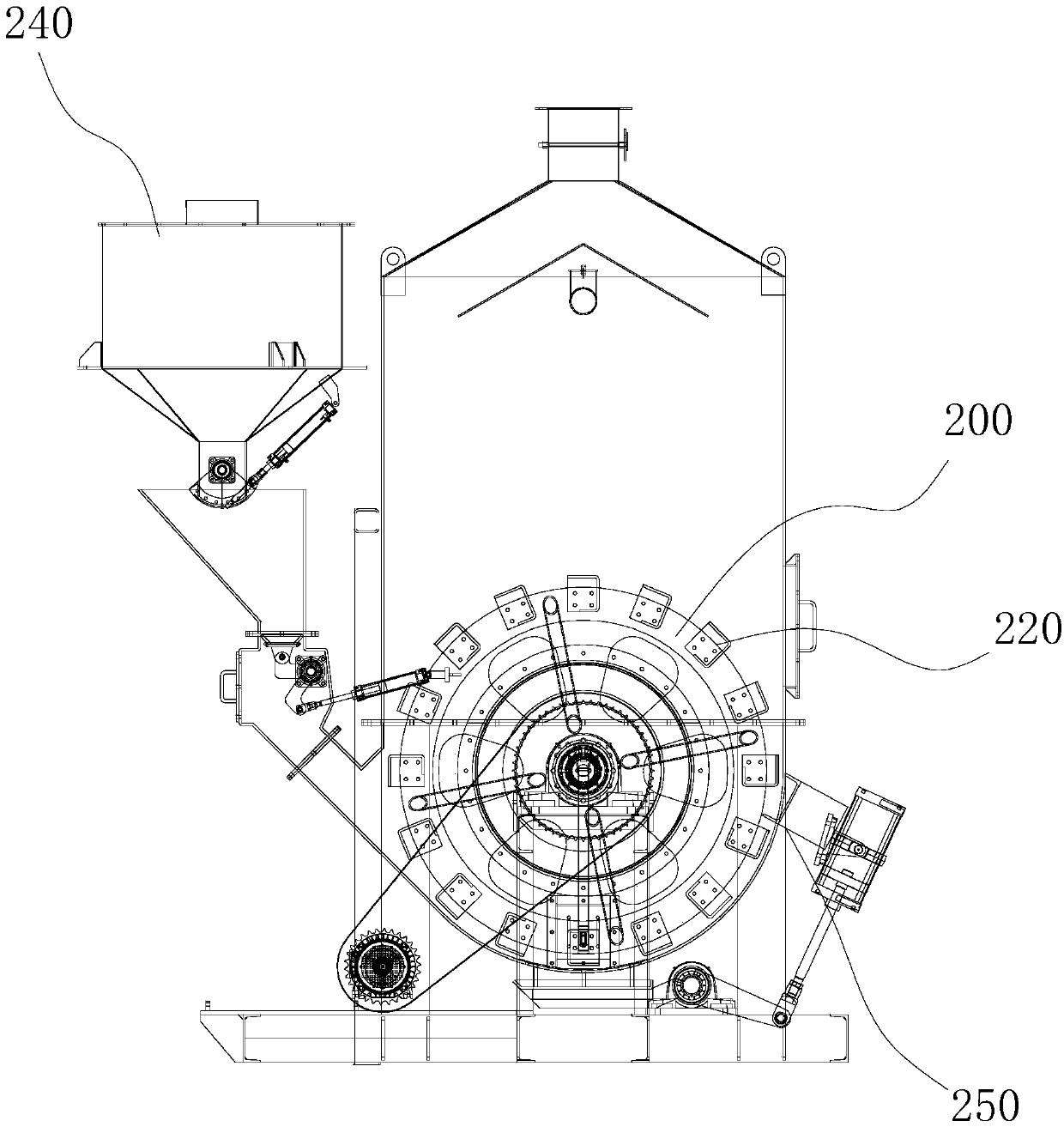

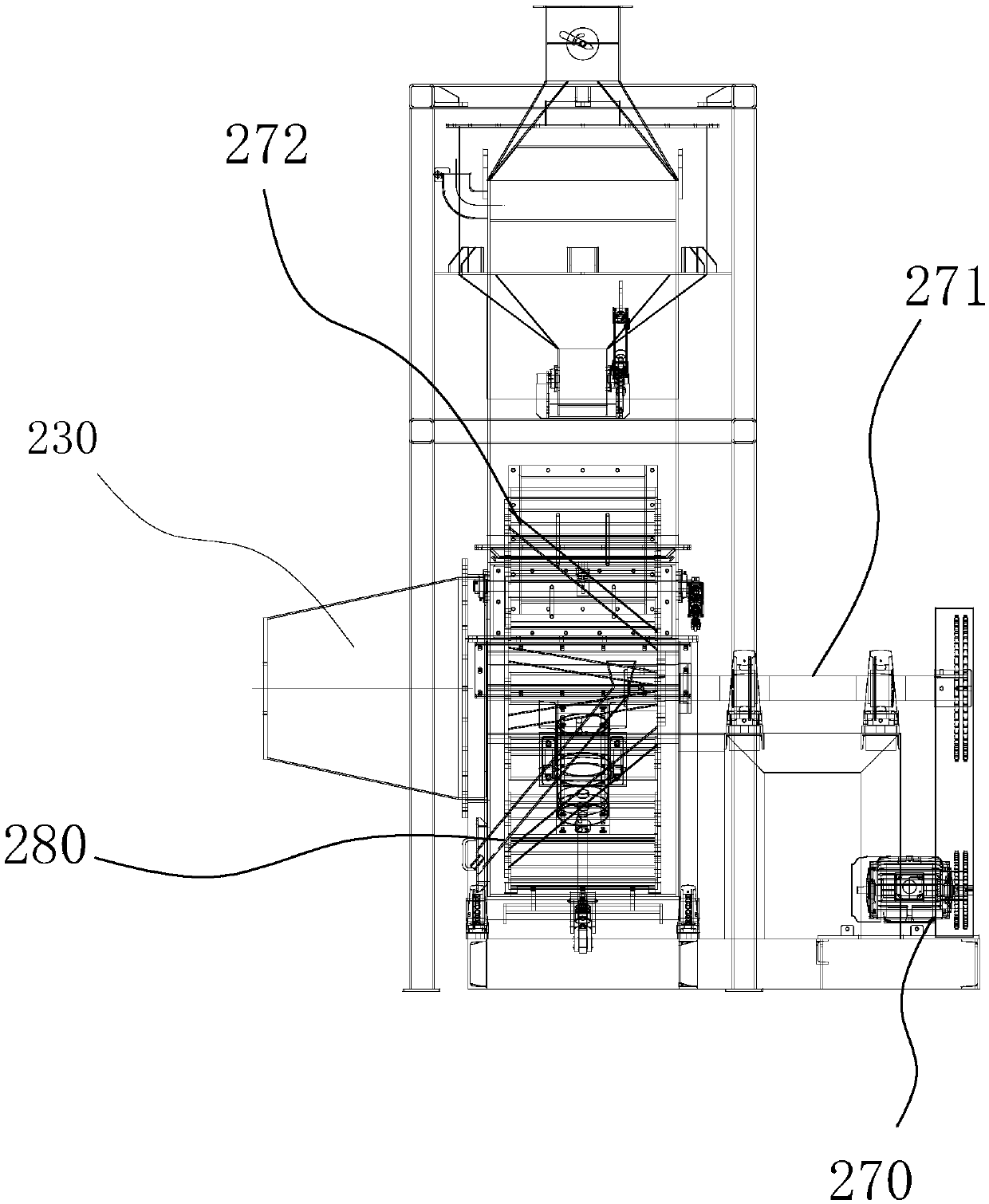

Precoated sand production line

PendingCN109590432AEven and stable heatingGood coating effectMould handling/dressing devicesProduction lineEngineering

The invention belongs to the technical field of precoated sand production and particularly relates to a precoated sand production line. The precoated sand production line comprises a raw sand materialbin, a heating machine, a mixer, a sieve shaker and a finished product material bin. A pair of stirring wheels are arranged inside the heating machine. The edge of each stirring wheel is uniformly provided with multiple sand stirring hoppers. The stirring wheels rotate to drive the sand stirring hoppers to move in the circumferential direction. The side face of the heating machine is provided with a burning machine, wherein the burning machine outputs heat to the rotating centers of the stirring wheels. The mixer is arranged below the heating machine and internally provided with a rotating disc. The rotating disc is provided with a pair of rolling wheels. The sieve shaker is internally provided with a crushing net. According to the precoated sand production line, materials are conveyed from a high position to a low position through gravity flow; a feeding hopper lifter and a discharging hopper lifter are adopted to assist in conveying, from the low position to the high position, of the materials; equipment is reasonable in arrangement, and energy is effectively saved; the heating machine conducts heating stably and uniformly; an eccentric double-grinding wheel of the mixer is goodin film coating effect; sand obtained after mixing is subjected to crushing, screening and cooling; a precoated sand product is excellent in quality; and the work efficiency is high.

Owner:天阳机械设备有限公司

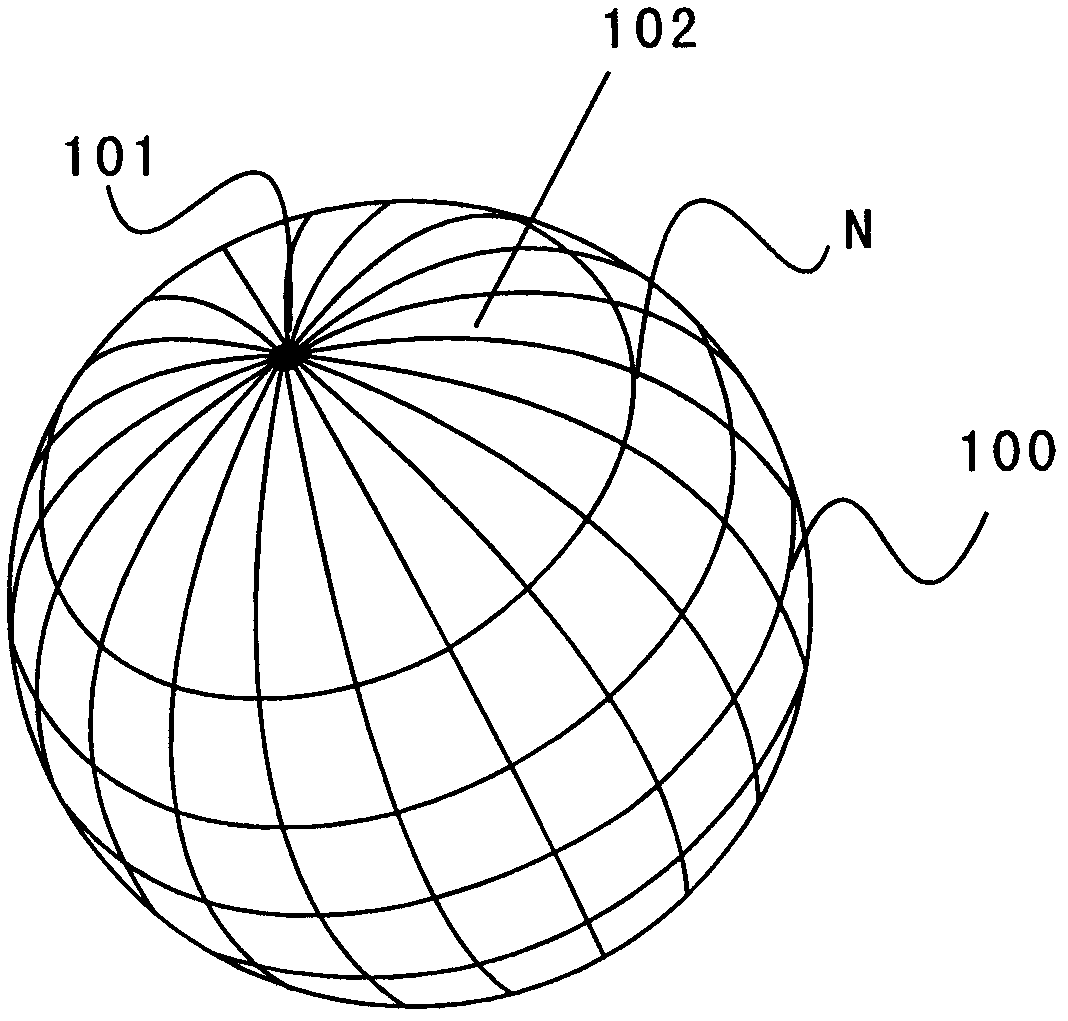

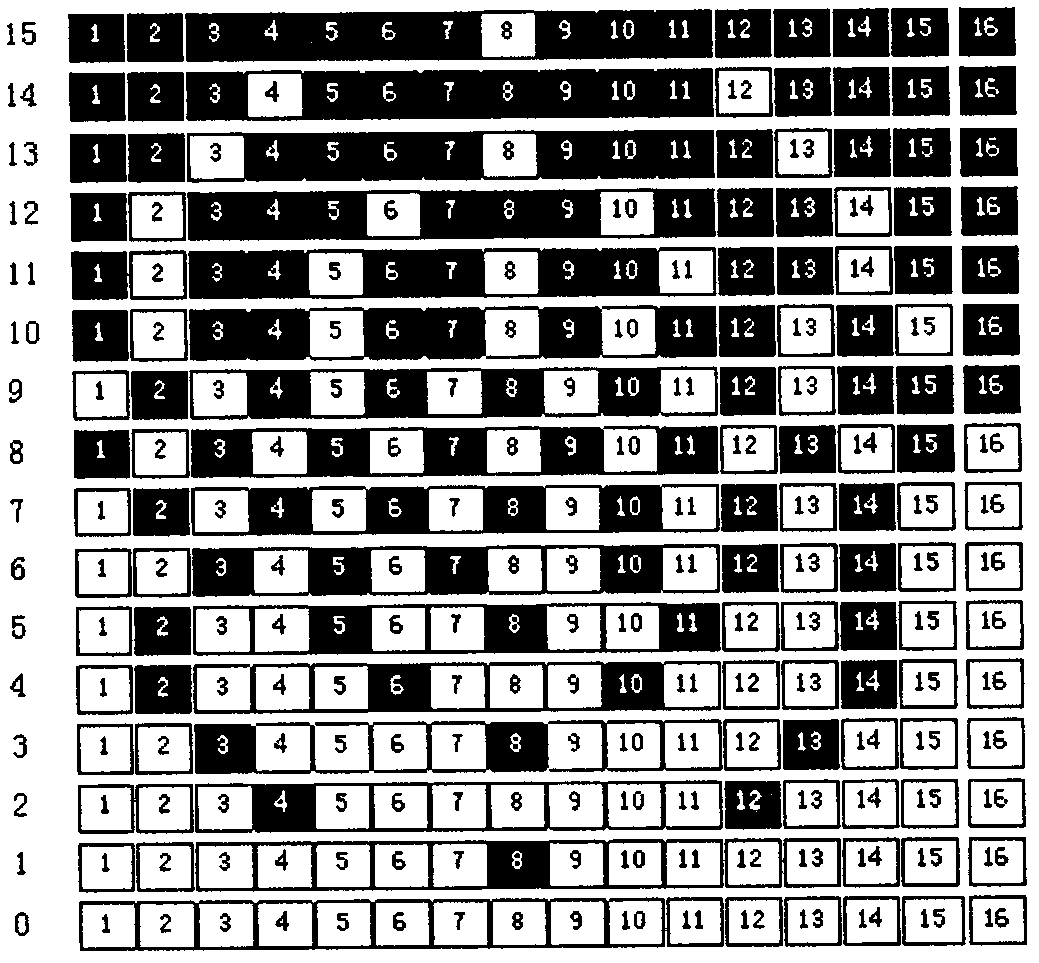

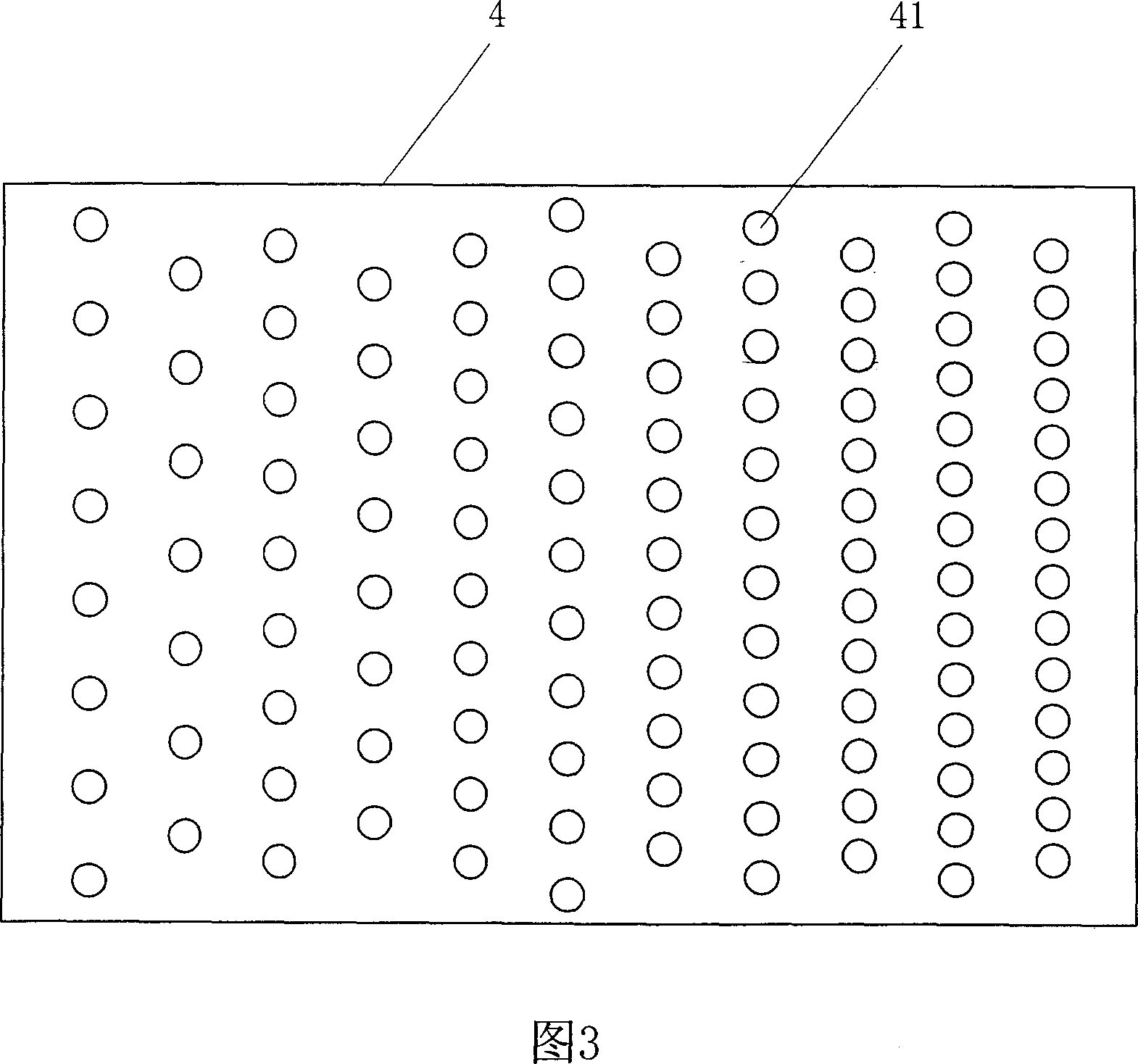

Pixel arrangement structure of spherical LED (Light-Emitting Diode) display screen

The invention provides a pixel arrangement structure of a spherical LED (light-emitting diode) display screen. The invention technically aims to provide the pixel arrangement structure of the spherical LED display screen, which has the advantages that pixels are orderly arranged and are reasonably increased and decreased; an image is complete; and the waste on the pixels cannot be caused. The pixel arrangement structure comprises a spherical body. The numbers of pixels on parallels on the spherical body are gradually decreased from the middle of the sphere to both poles of the sphere. The decreasing numbers of each two adjacent lines of pixels on the parallels meet the following relation: when N / X is less t than A, X-Y, wherein N represents a unit parallel length; X represents a pixel number; Y represents a reduced pixel number; A represents a pixel spacing value; N / X represents a forecast pixel spacing value; and the distances between the pixels on the parallels are consistent. The pixel spacing A on the adjacent parallels is allowed to have an error of A plus and minus A*10%. The display screen disclosed by the invention is uniform to display the image, cannot cause waste and is applicable to use in the spherical display screen.

Owner:SHENZHEN APEXLS OPTOELECTRONICS

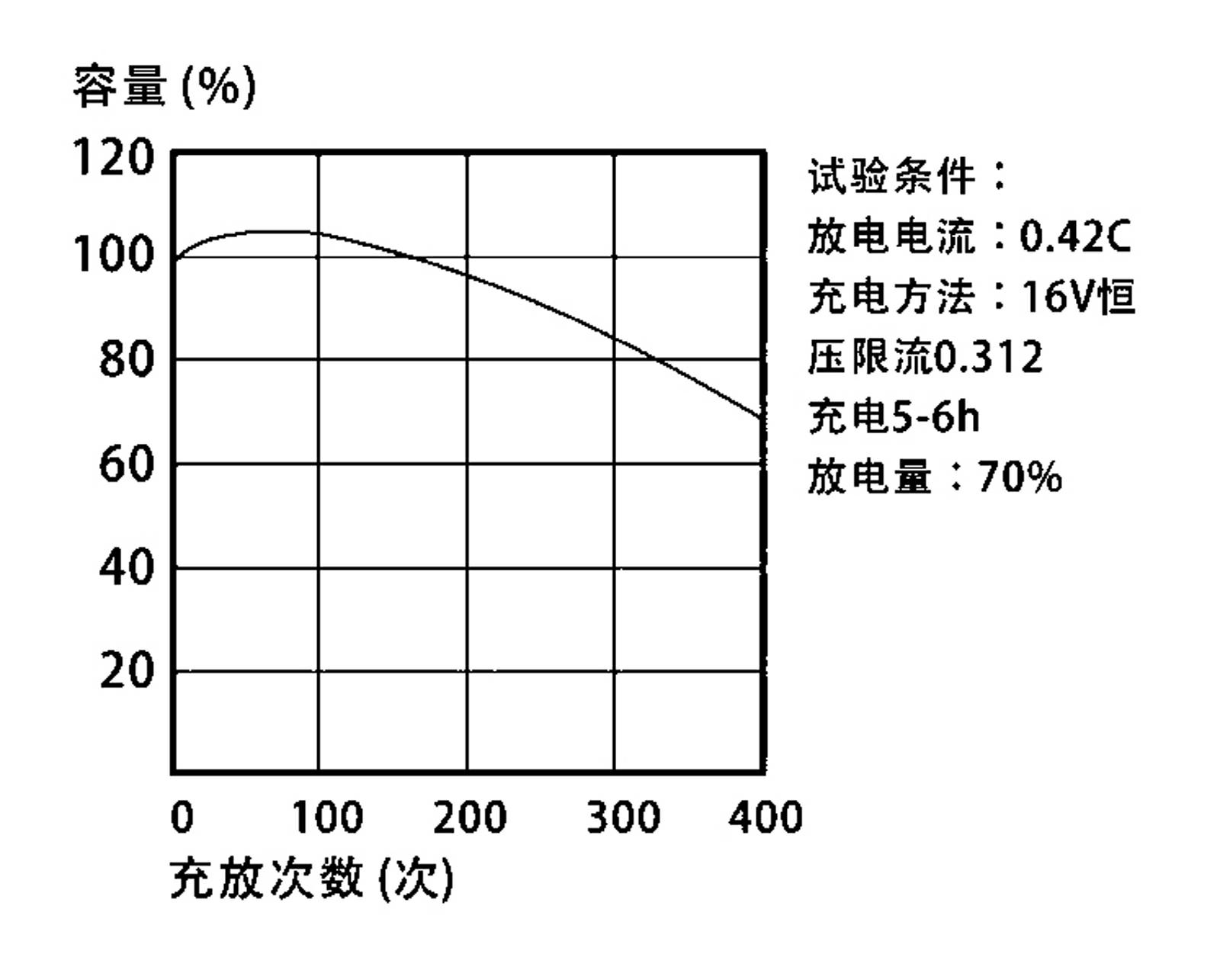

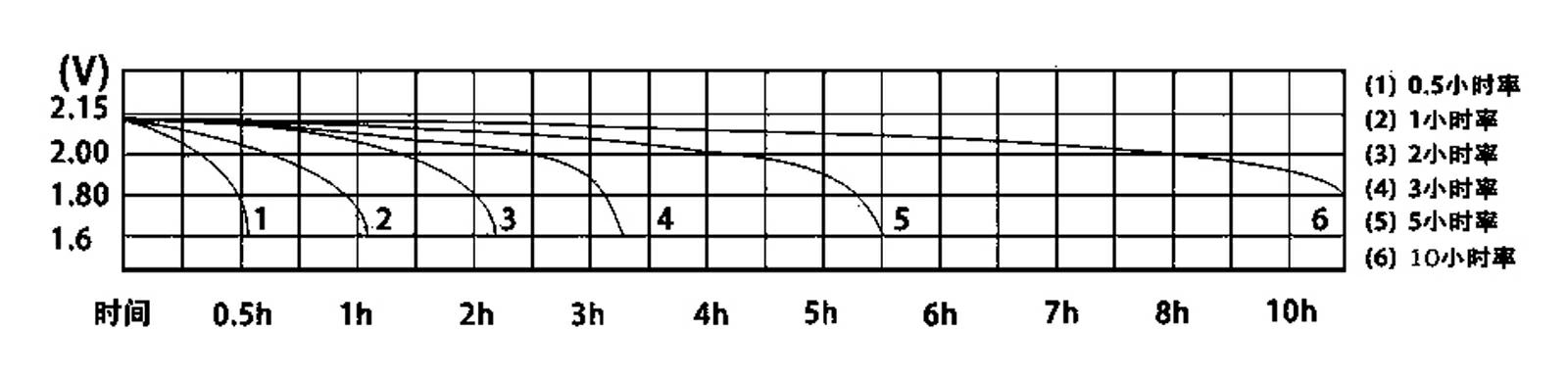

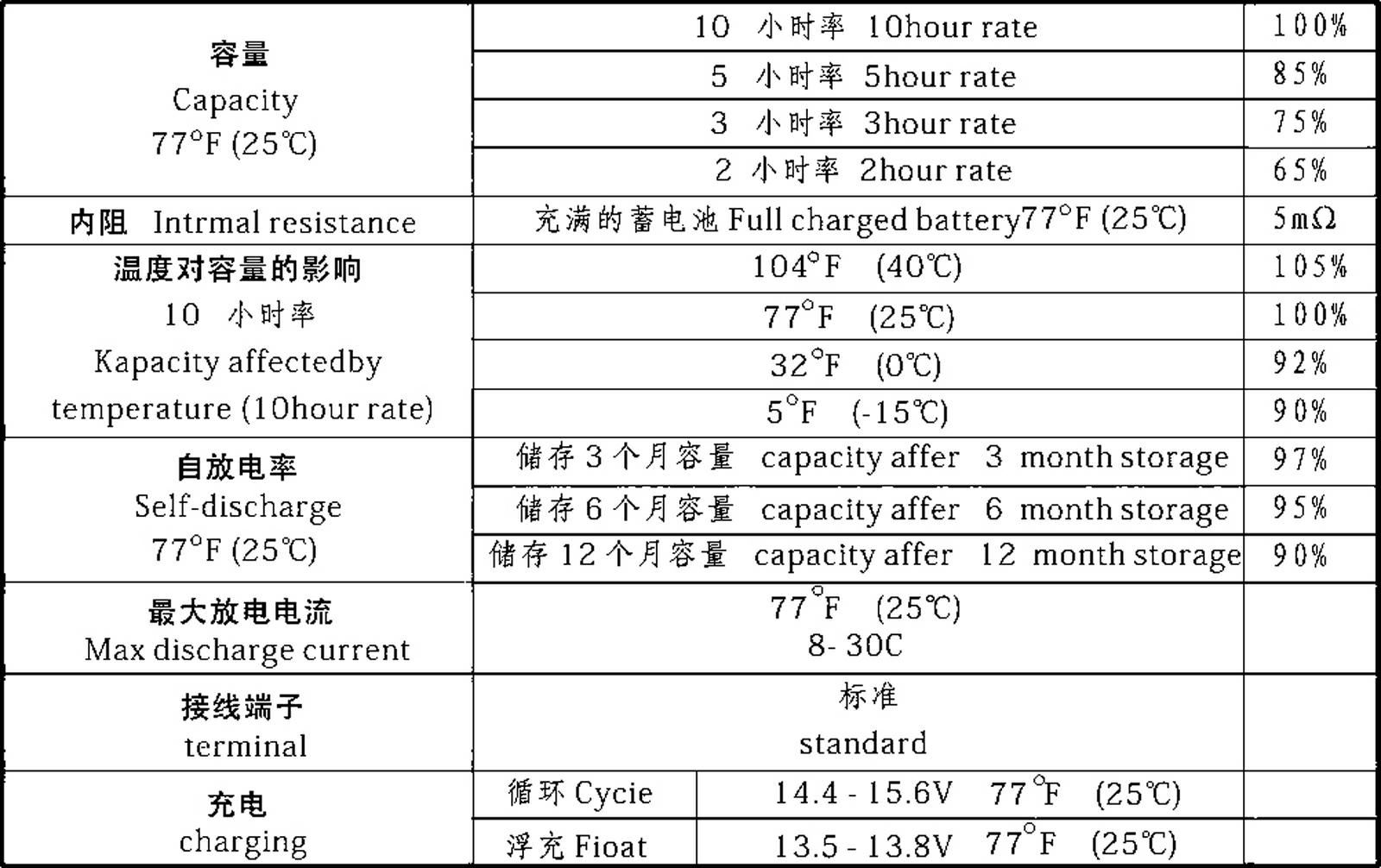

Silicate electrolyte for battery and preparation method thereof

ActiveCN102122730AWill not polluteIncrease oxygen contentLead-acid accumulatorsElectrolytic agentPtru catalyst

The invention discloses a silicate electrolyte for a battery, and the electrolyte comprises the following components by weight percent: 20-45% of sulfuric acid, 1-2% of ammonium phosphate, 10-15% of silicon dioxide, 2-3% of ammonium persulfate, 1-1.5% of sodium sulfate, 1-1.5% of potassium sulfate, 1-2% of polyacrylamide, 1-2% of dispersant, 2-3% of stabilizer, 3-5% of catalyst and the balance ofdeionized water, wherein the catalyst is one of basic salt, silane and silicone oil. The silicate electrolyte has the advantages of good performance, environment friendliness and favorable industrialapplication prospect.

Owner:李海明

Vacuum belt press filter

InactiveCN101612805BEasy to cleanRealize automatic continuous operationCleaning using liquidsPressesFiltrationPulp and paper industry

The invention relates to a vacuum belt press filter, comprising a rack, a vacuum filtration assembly, a press assembly and a filtration belt assembly, wherein the filtration belt assembly comprises an upper filtration belt, a lower filtration belt, and a cleaning device A and a cleaning device B which are used for respectively cleaning the upper filtration belt and the lower filtration belt; the cleaning device B comprises a front guide roller and a rear guide roller on the motion direction of the lower filtration belt, the front guide roller is arranged on the upper face the lower filtrationbelt, closely contacts the lower filtration belt and enables the lower filtration belt to form a V shape, the rear guide roller is arranged on the lower face of the lower filtration belt and is provided with a plurality of pinpricks, the size of each pinprick is matched with the size of a filtration pore of the filtration belt, and the rear guide roller contacts with the lower filtration belt by the pinpricks; and the cleaning device B is provided with a plurality of spray heads, and the spray heads are distributed on the upper face and the lower face of the lower filtration belt. The vacuum belt press filter of the invention has the advantage of favorable cleaning effect of the filtration belts, and belongs to the technical field of press machines.

Owner:HUZHOU HEHONG MACHINERY

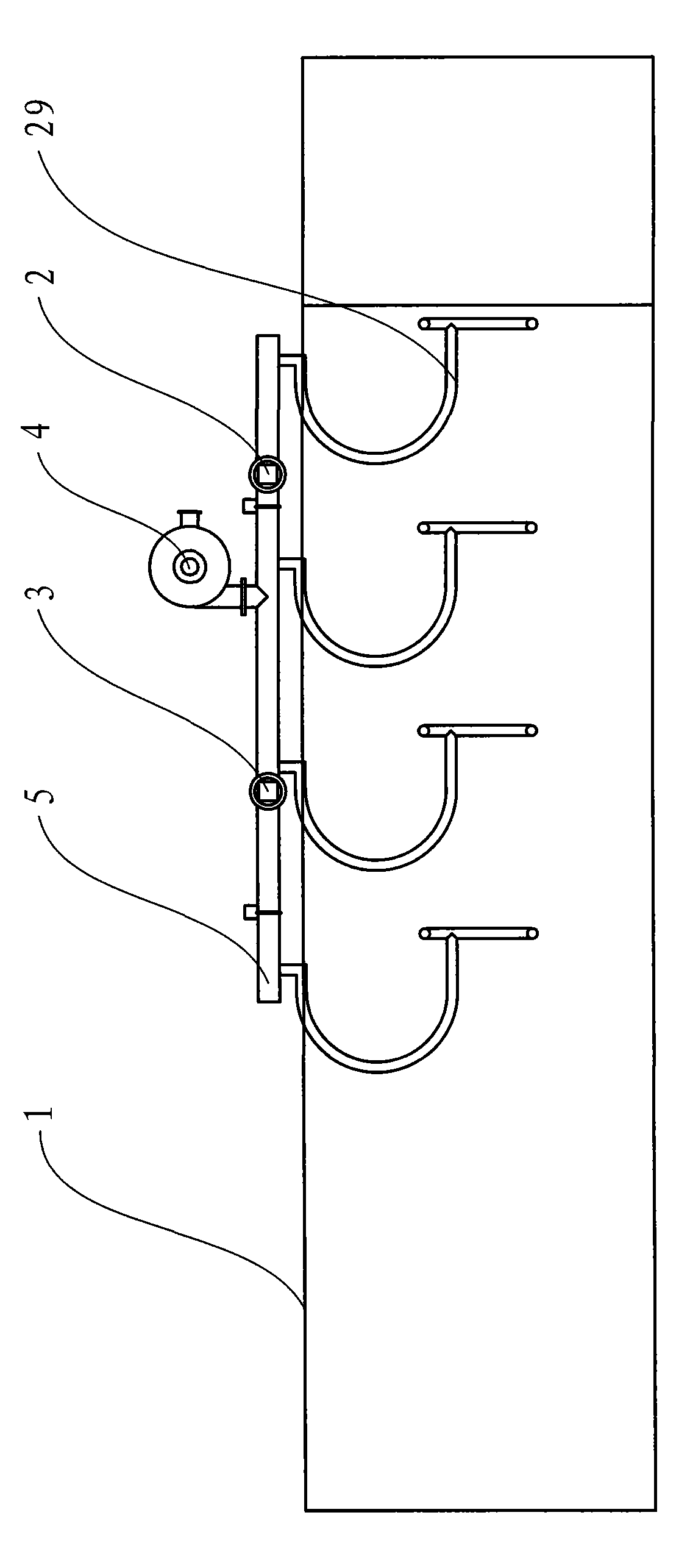

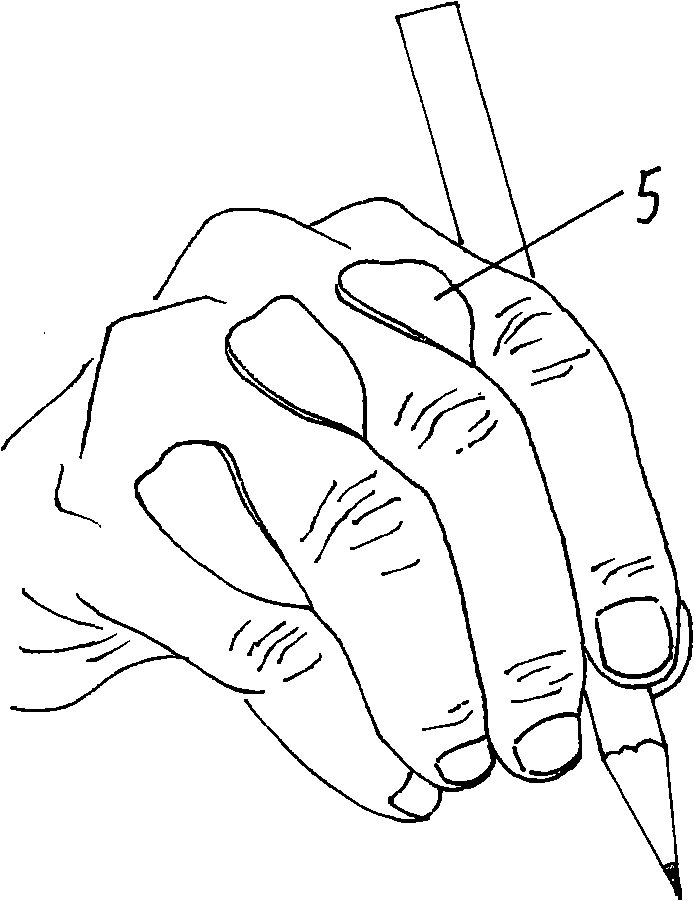

Holding pen appliance for infant and middle and primary school students

A pen holder which is suitable for infants and the students of elementary schools and middle schools to use consists of a circular supporting surface (1) manufactured by silicon rubber by the methods of molding, glue injection, demoulding, internally arranging a steel wire, and the like; a supporting steel wire (2) in the supporting surface; four finger conducting grooves (3) at the back surface of the supporting surface; connection sheets (4) and anti-falling baffles (5) at the top end of the connection sheets; when in use, the back surface of the circular supporting surface is held by right hand palm; the middle finger, the ring finger and the little finger are respectively contacted with the corresponding finger conducting grooves; the connection sheets are respectively clamped between the gaps of the forefinger, the middle finger, the ring finger and the little finger; the anti-falling baffles (5) at the top end of each connection sheet are transversely stuck on the corresponding back of the fingers; the pen is held by the thumb and the forefinger; a pen-holder is arranged at the middle finger and fingernails are exposed; the middle finger, the ring finger and the little finger are arranged in parallel in a ladder overlapping structure to lead the little finger and the edge of the palm to form a spoon shape. The pen holder of the invention has the advantages of simple structure, being easy to manufacture, flexible material and elasticity, which can not generate fatigue when being used for a long time. The pen holder of the invention is beneficial to forming correct pen holding pose and is suitable for infants and the students of elementary schools and middle schools to use.

Owner:曹元平

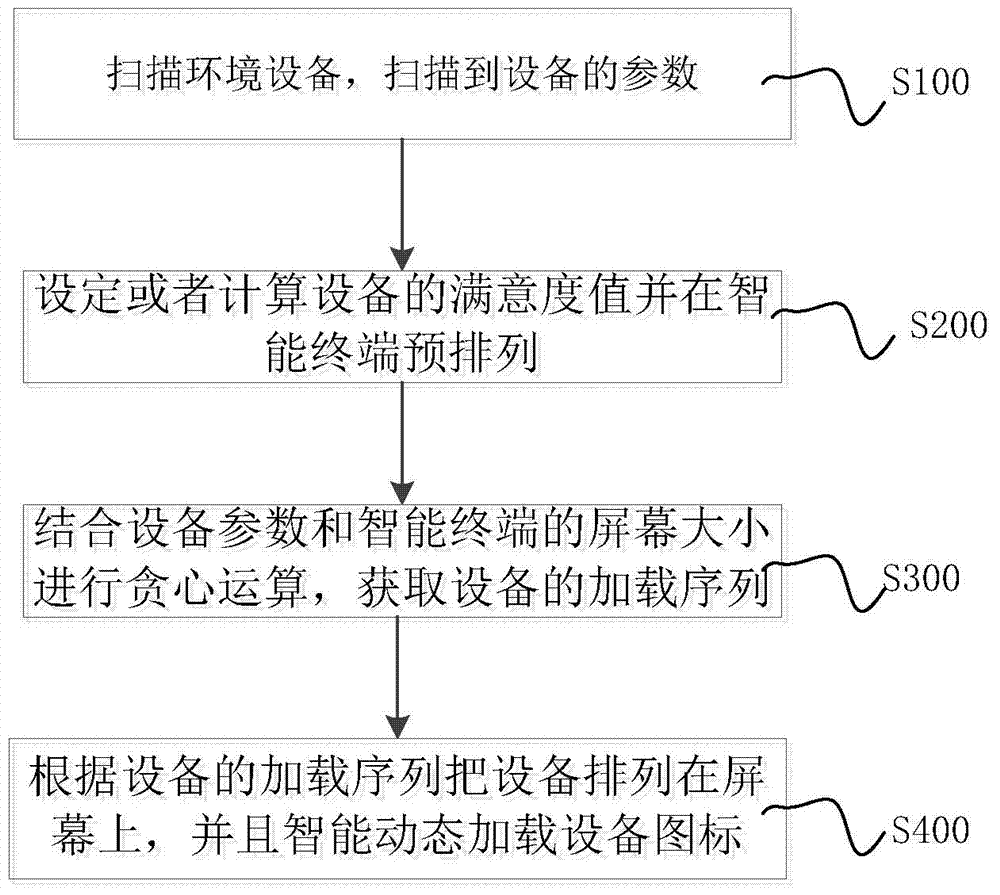

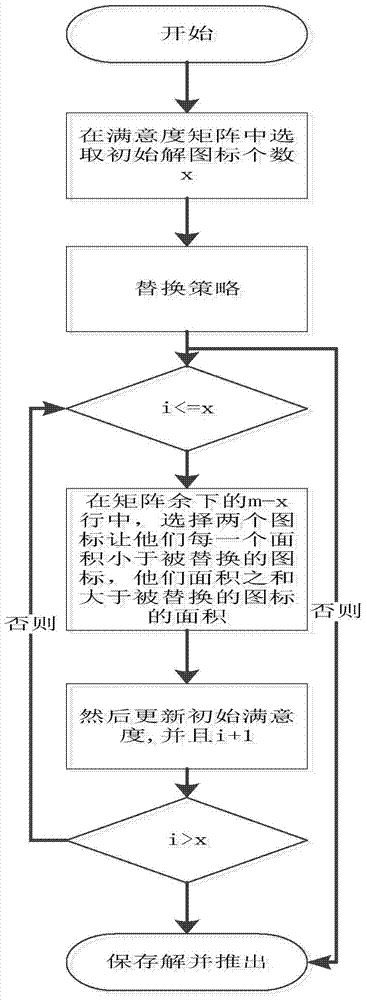

Intelligent terminal complete icon arrangement method and device

ActiveCN104850306AAvoid the disadvantage of easy local convergenceReasonably arrangedInput/output processes for data processingSimulationData complexity

The invention provides an intelligent terminal complete icon arrangement method and device. The method comprises the following steps: an intelligent terminal scans equipment in an intelligent domestic environment to obtain parameters of the equipment and a screen size of the intelligent terminal, wherein the parameters comprise the quantity of the equipment, icons, icon sizes and utilization frequency; satisfaction degree values of the equipment are set and are pre-arrayed on the intelligent terminal; the equipment parameters and the screen size of the intelligent terminal are combined to carry out greedy operation to obtain a loading sequence of the equipment; and the intelligent terminal dynamically loads the equipment icons according to the loading sequence of the equipment. According to the intelligent terminal complete icon arrangement method and device, a plurality of corresponding solutions are provided for complete icon selection and arrangement problems when the data complex rates are different; and the method is simple and rapid, the icons are arrayed reasonably and the user practicability is enhanced.

Owner:济宁高新科达科技项目服务有限公司

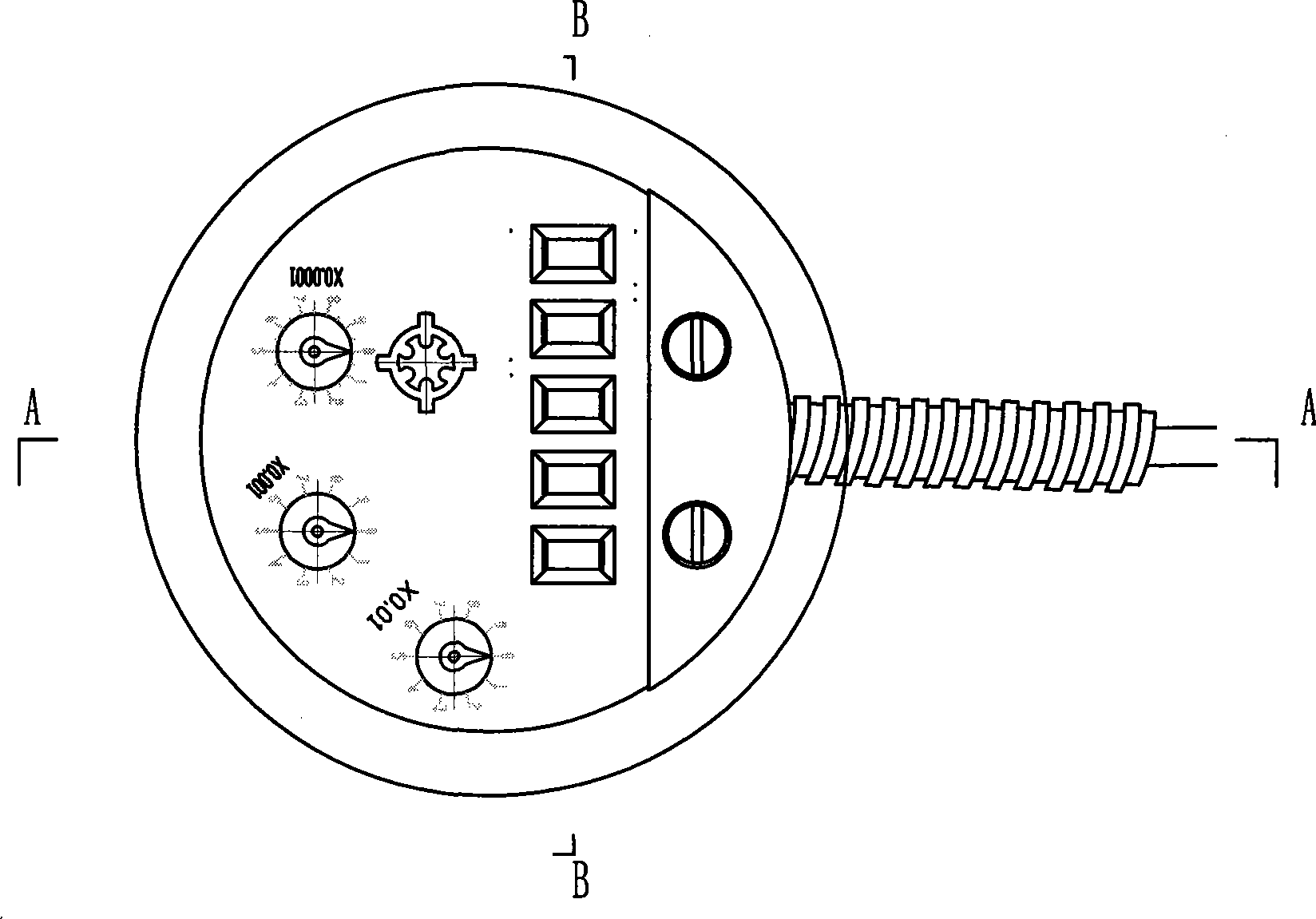

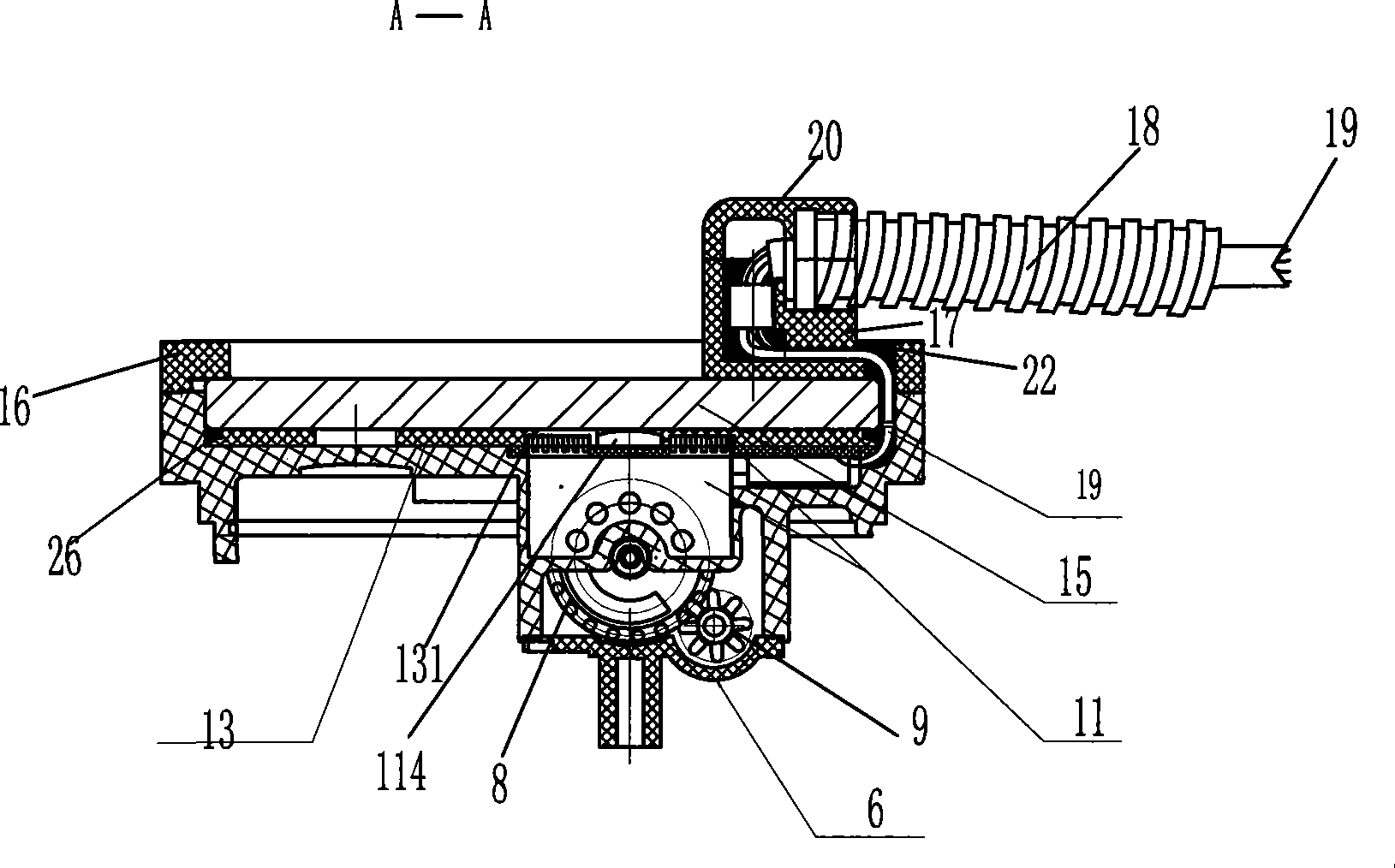

Liquid seal electronic direct-reading water meter

InactiveCN101368832AEffective protectionAvoid Insufficient SealingVolume indication and recording devicesVolume/mass flow by mechanical effectsImpellerEngineering

A liquid sealed electronic direct reading water meter comprises a dial, a photovoltaic module, a counting mechanism of a liquid sealed character wheel box, and an impeller measuring mechanism with upper and lower splints; the photovoltaic module is arranged above the liquid sealed character wheel box and separated from the character wheel by a partition board with interval grooves on both sides; a photovoltaic panel of the photovoltaic module at the upper part and the character wheel at the lower part are respectively positioned at both sides of the partition board and are corresponding to each other; and the corresponding positions on the photovoltaic module corresponding to the figures on the character wheel are provided with openings or are transparent. The liquid sealed electronic direct reading water meter has the advantages of effectively protecting the photovoltaic module and overcoming the disadvantage that the original structure needs to use special glue layer to seal the photovoltaic module, under the premise of ensuring a clear reading; besides, the production of the water meter is simpler, so that the production efficiency can be improved and the production cost is reduced; at the same time, the lead wire of the photovoltaic module can be directly and easily educed out, and has lower sealing requirements. Only a simple sealing at the lead wire position can easily and rapidly solve the sealing problem of the entire photovoltaic module space.

Owner:NINGBO KEYTURE TECH CO LTD

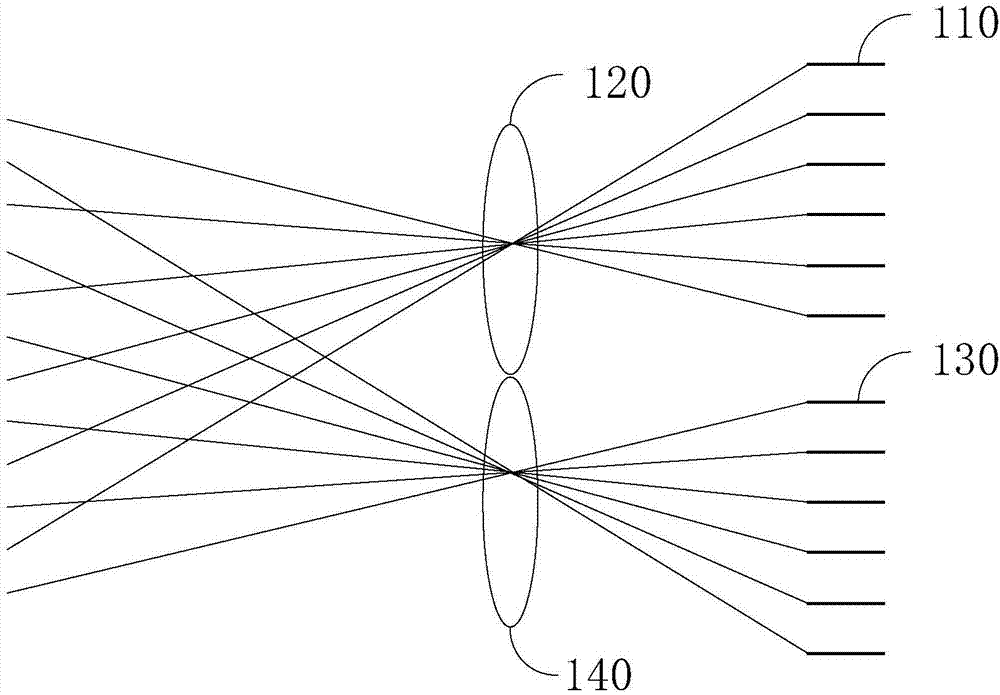

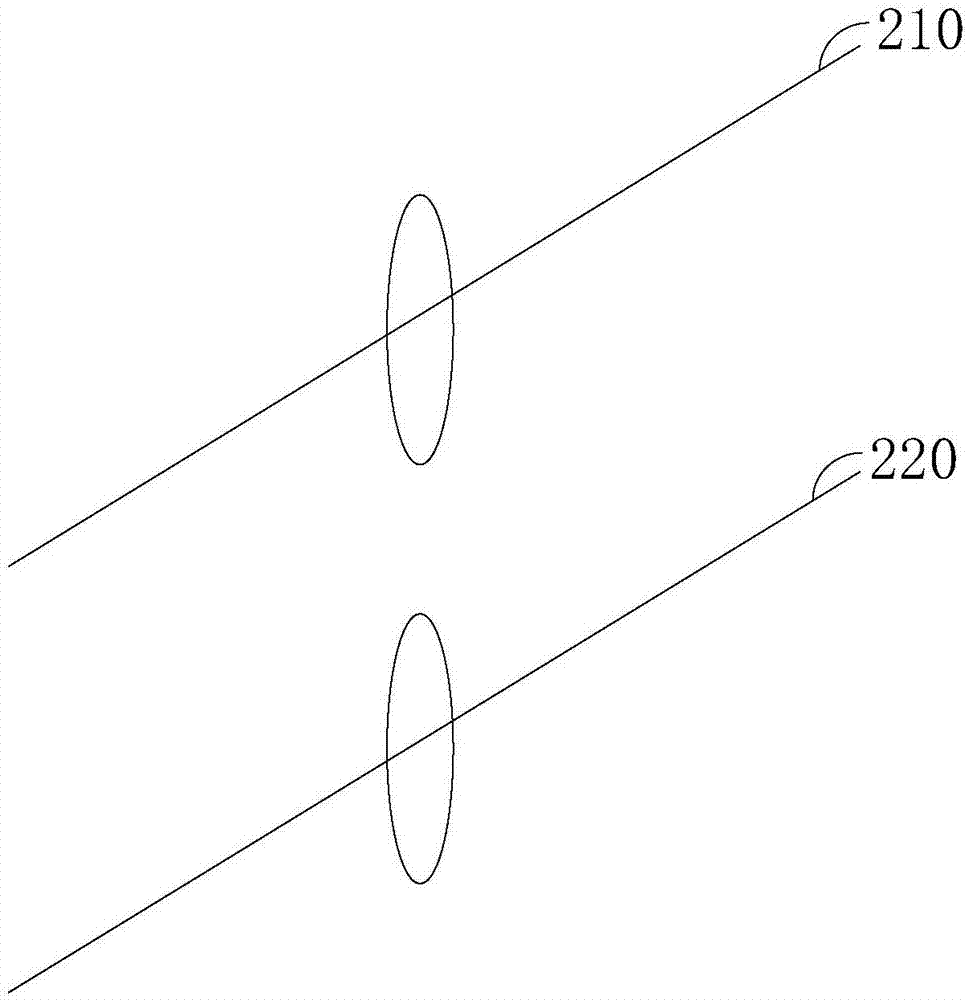

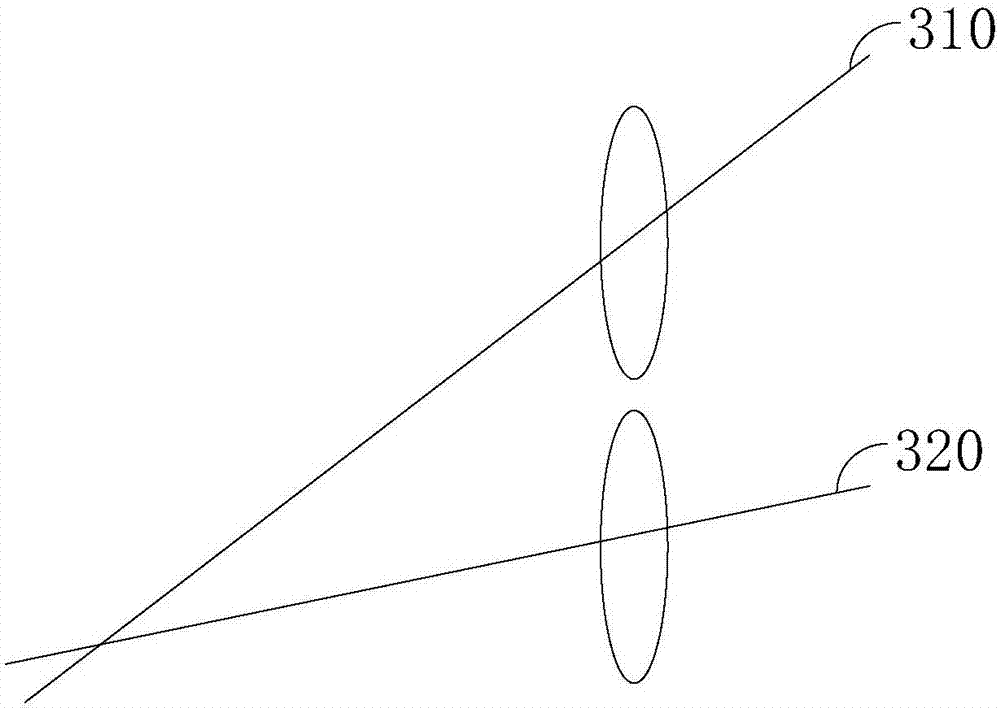

Laser radar and laser radar control method

PendingCN107153182AIncrease vertical resolutionSmall sizeWave based measurement systemsEngineeringMechanical engineering

The embodiment of the invention discloses a laser radar and a laser radar control method. The laser radar comprises a first group of laser emitting units for emitting a first group of emergent laser, a first transmitting end collimating unit for collimating the first group of emergent laser, a second group of laser emitting units for emitting a second group of emergent laser and a second transmitting end collimating unit for collimating the second group of emergent laser. Therefore, the vertical resolution of the laser radar can be improved and the size of the laser radar can be reduced.

Owner:SUTENG INNOVATION TECH CO LTD

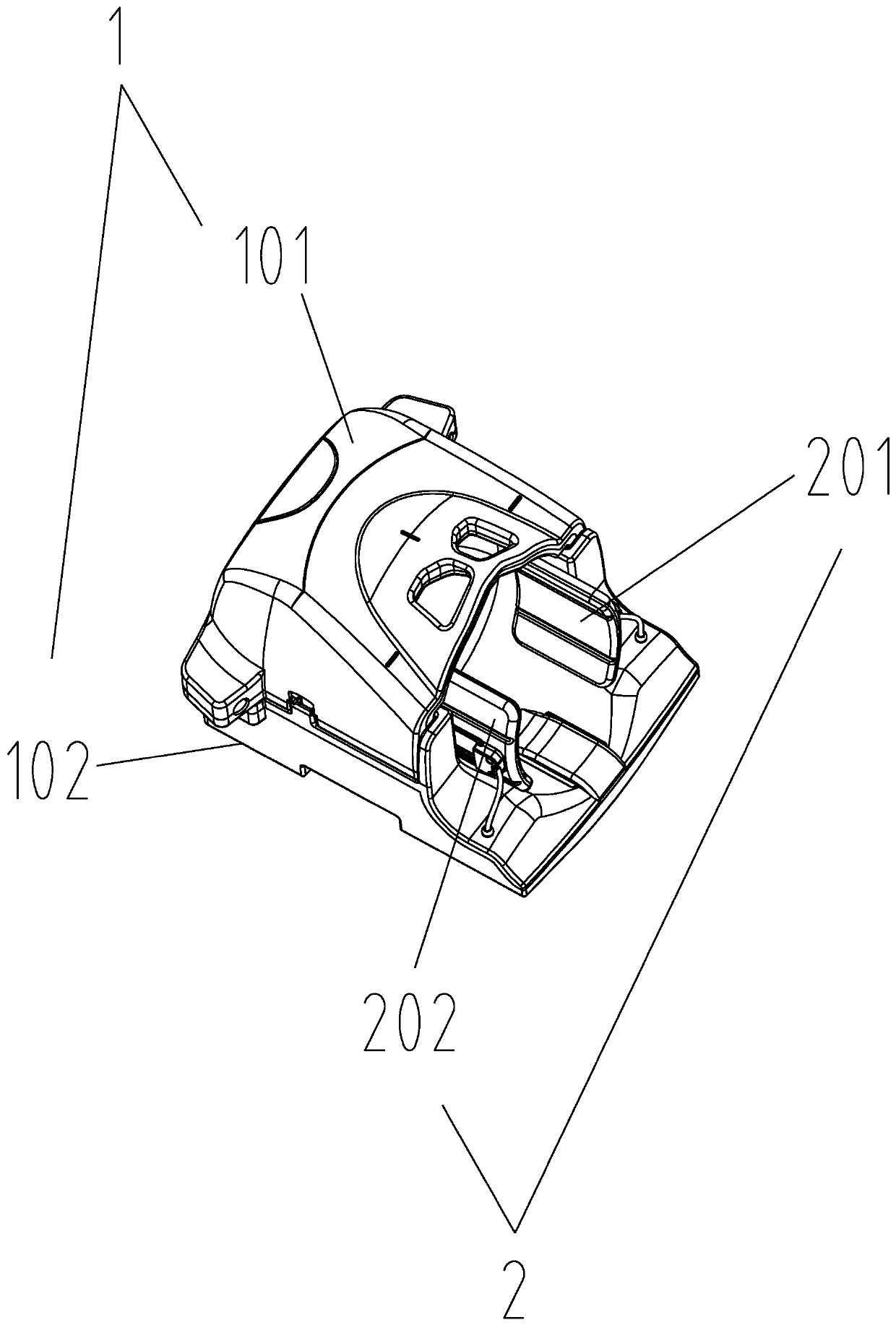

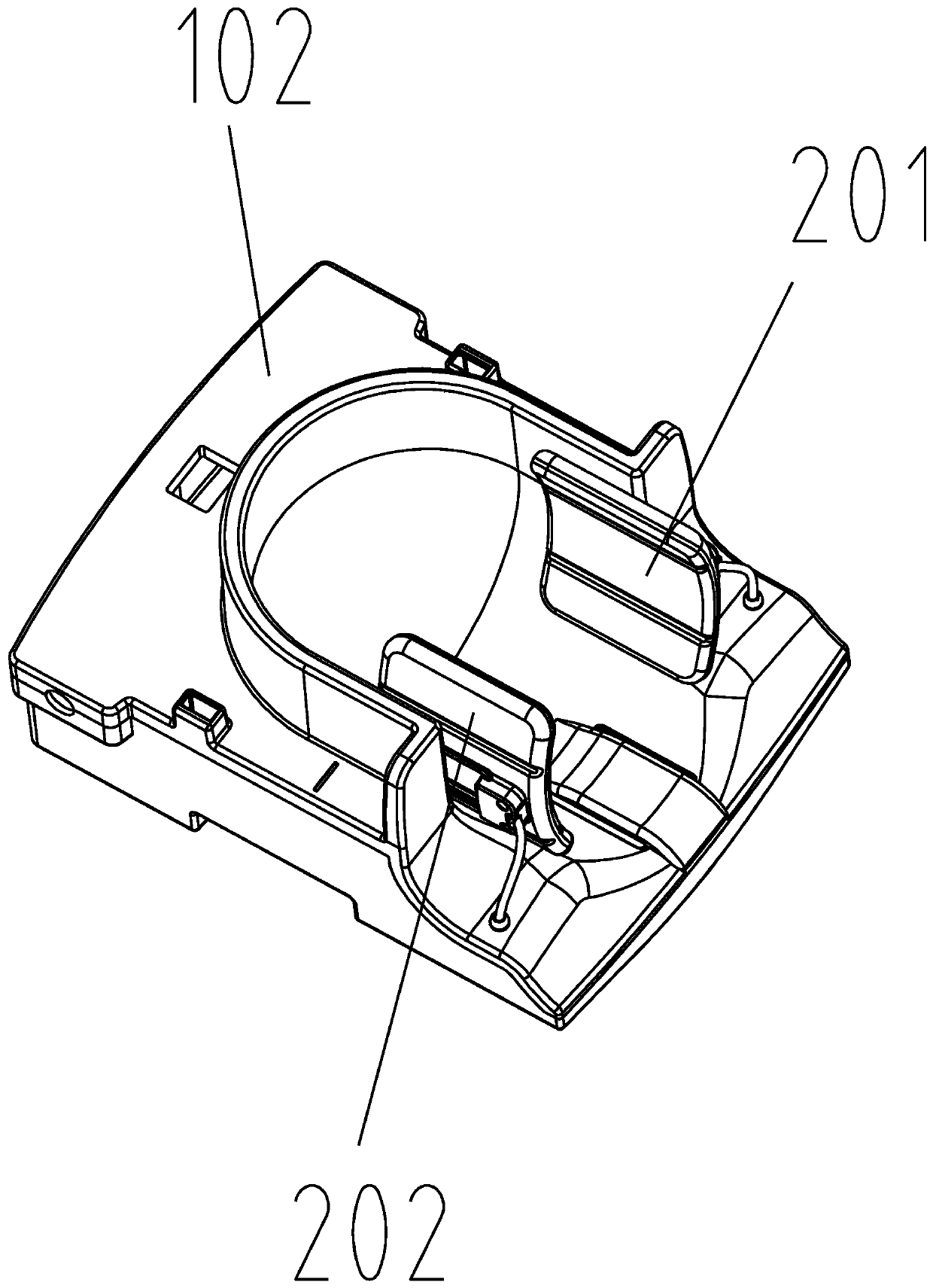

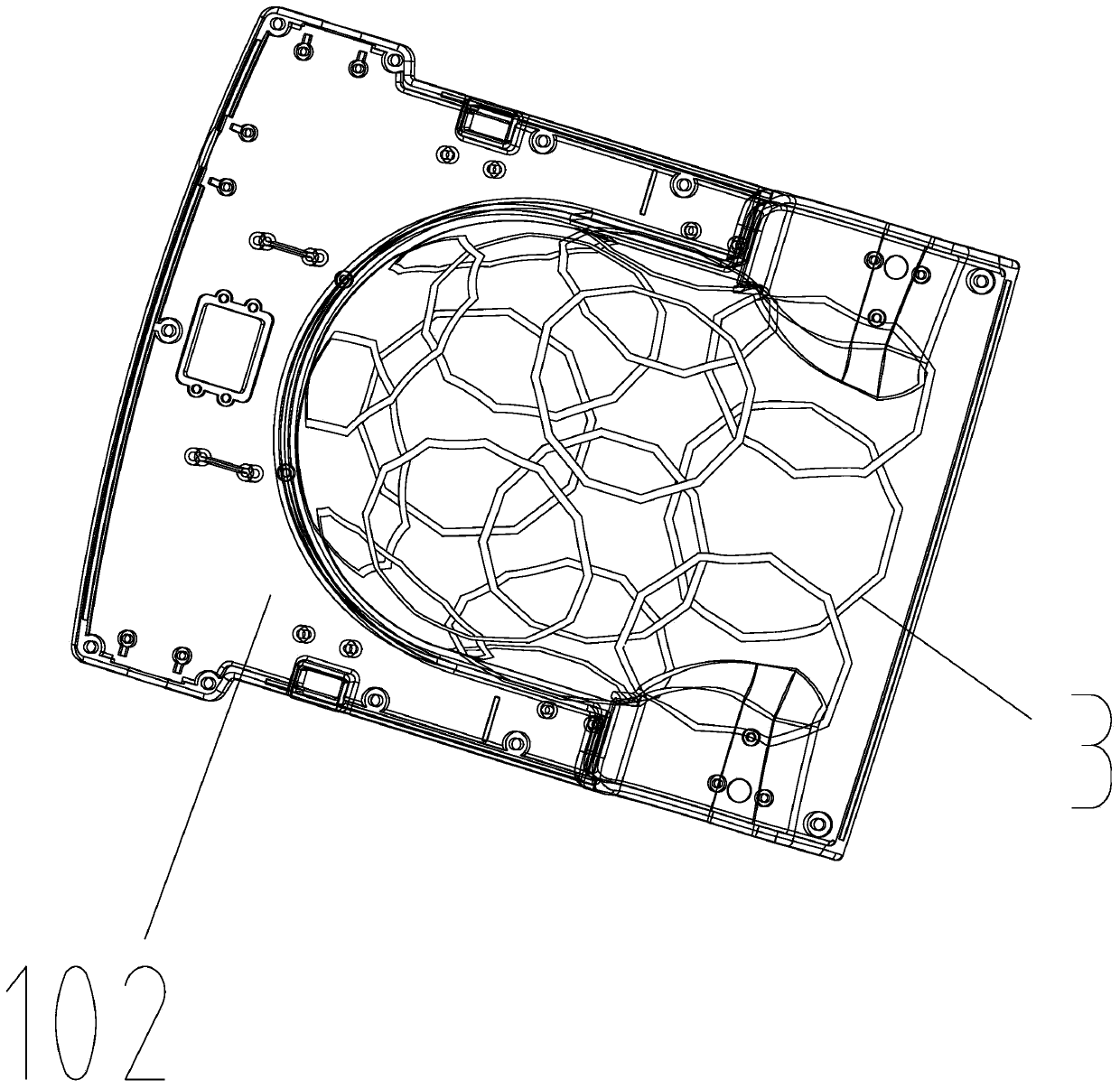

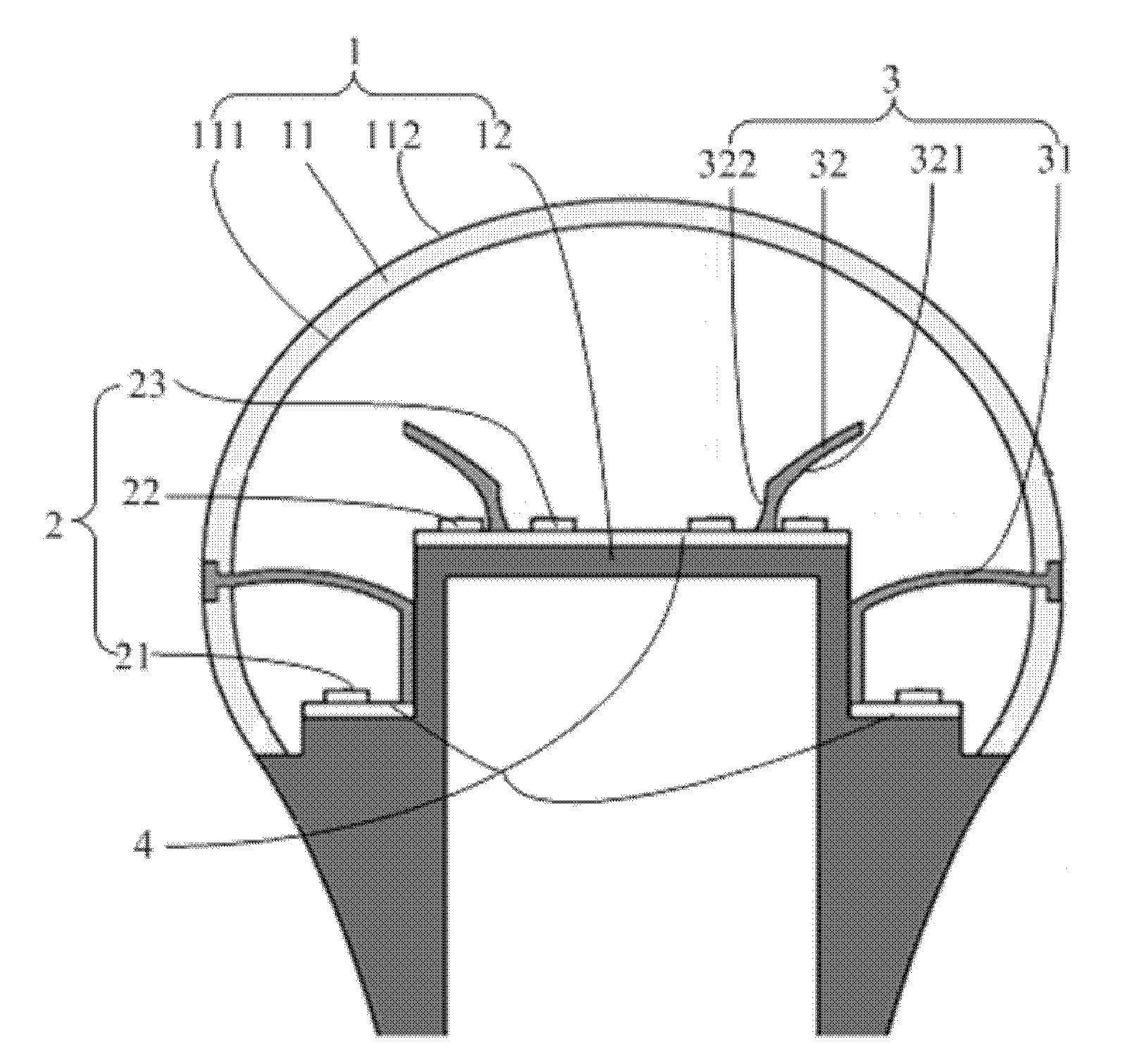

Radio frequency coil device for magnetic resonance head and neck imaging

PendingCN110286342AImprove experienceEasy to wearMeasurements using magnetic resonanceLeft halfResonance

The invention discloses a radio frequency coil device for magnetic resonance head and neck imaging. The radio frequency coil device comprises a coil supporting shell and a plurality of annular coil units fixed onto the shell wall of the coil supporting shell; the coil supporting shell is composed of a head coil supporting shell and a neck coil supporting shell, a head containing cavity being defined in the head coil supporting shell, a neck containing cavity being defined in the neck coil supporting shell; the head coil supporting shell is composed of a front half shell located at the front side of the head of a person to be examined and a rear half shell located at the back side of the head of the person to be examined; the neck coil supporting shell is composed of a left half shell located at the left side of the neck of the person to be examined and a right half shell located at the right side of the neck of the person to be examined; and a plurality of coil elements are fixedly arranged in the shell walls of the front half shell, the rear half shell, the left half shell and the right half shell. The various coil units in the device are reasonable in arrangement and dense in distribution, and therefore, the advantage of partial overlapping decoupling is utilized to the greatest extent, and the effect of the head and neck imaging is improved.

Owner:SUZHOU MEDCOIL HEALTHCARE

Cultivation production process of Hanfu apples

InactiveCN101965793APremature Cultivation and Production TechnologyStable yield cultivation production processCultivating equipmentsFruit treeMain branch

Owner:李茂生 +1

Light emitting diode (LED) full light angle bulb

InactiveCN102563428AExtend your lifeIncrease powerPoint-like light sourceElectric circuit arrangementsDesign spaceLight-emitting diode

The invention provides a light emitting diode (LED) full light angle bulb, which comprises a lamp housing and a light source and a reflecting unit which are arranged in the lamp housing, wherein the light source at least comprises a first light source group, a second light source group and a third light source group; the reflecting unit at least comprises a first reflector and a second reflector; the lamp housing is partitioned into a first area, a second area and a third area by the first reflector and the second reflector; and the first light source group, the second light source group and the third light source group are respectively correspondingly arranged in the first area, the second area and the third area. The heat produced by the light source in the LED full light angle bulb is distributed uniformly, so that the service life of the bulb is prolonged; the design space of a power supply is enlarged, and the power of the bulb can be improved as required; and the contour of the bulb can be made to be as same as that of a classical filament lamp so as to accord with the traditional aesthetic standard.

Owner:SHENZHEN H & T INTELLIGENT LIGHTING CO LTD

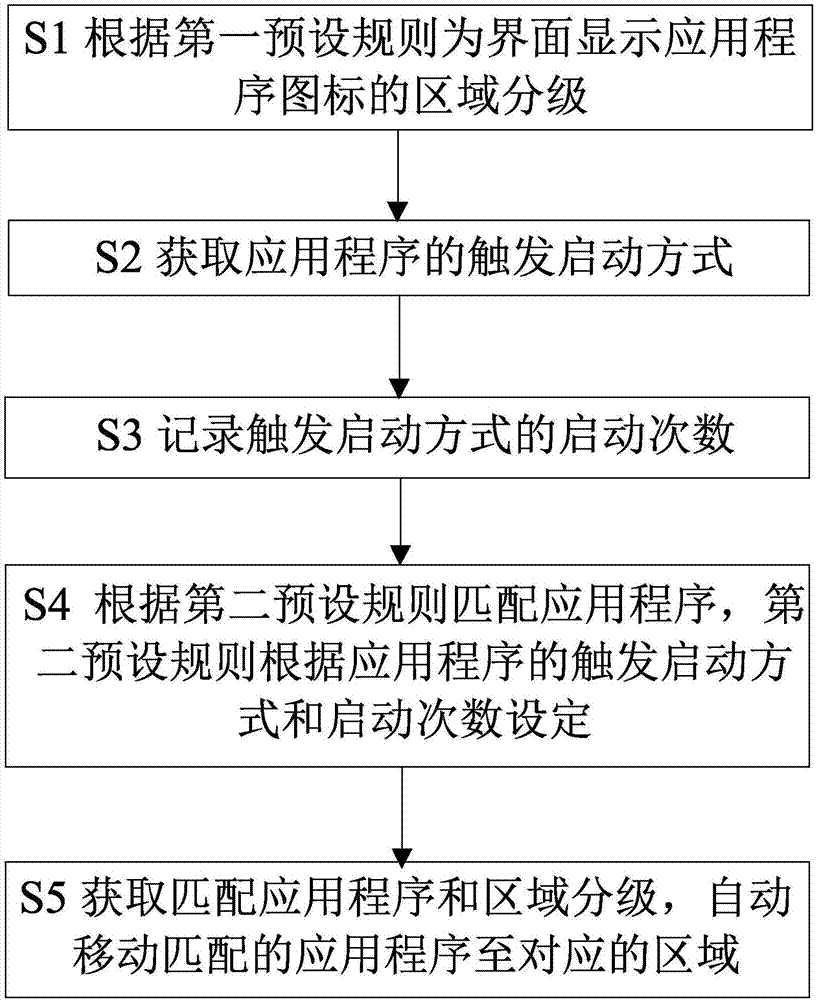

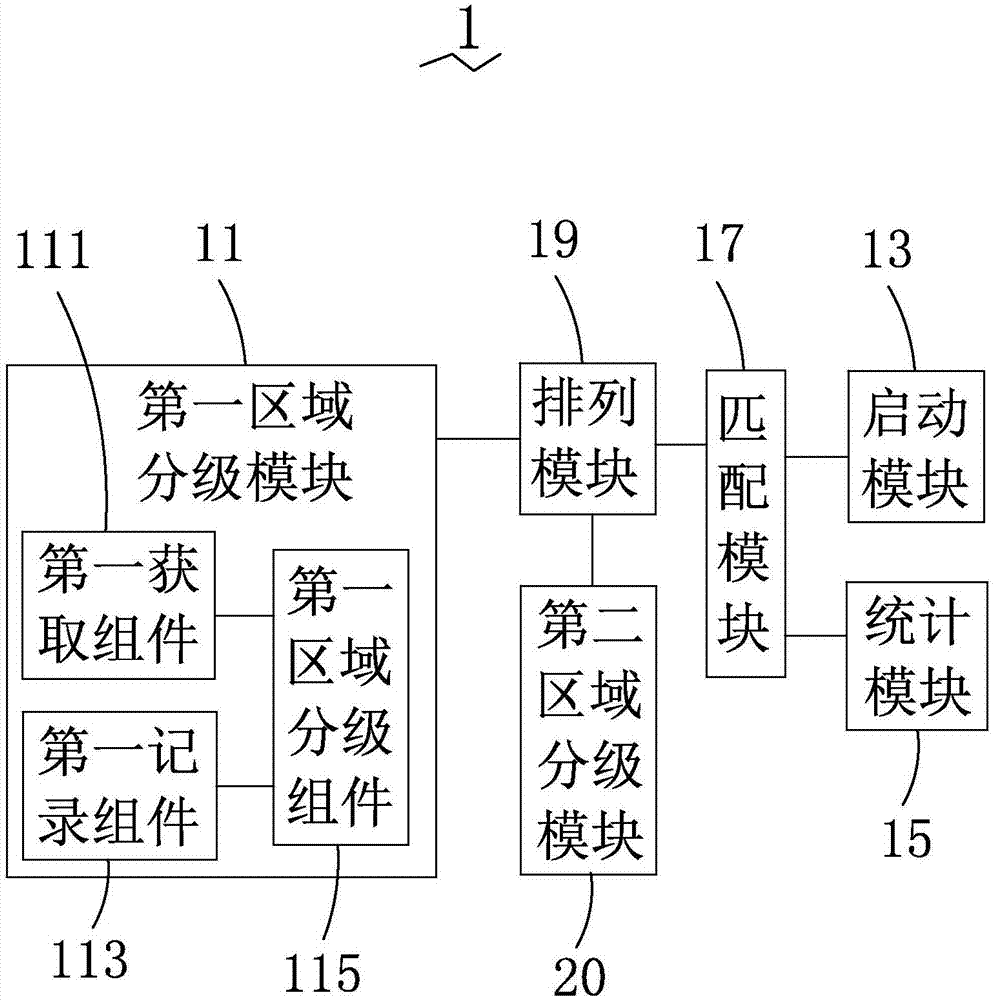

Method and terminal for arranging application icons

PendingCN107220068AGood for arrangementReasonably arrangedSpecific program execution arrangementsInput/output processes for data processingStart timeComputer hardware

The invention provides a method and terminal for arranging application icons. The method for arranging application icons comprises the following steps: S1, carrying out area classification on interface display application icons according to a first preset rule; S2, acquiring a triggering starting mode of applications; S3, recording the starting times of the triggering starting mode; S4, matching the applications according to a second preset rule which is set according to the triggering starting mode of the applications and the starting times; and S5, acquiring matched applications and area classification, and automatically moving the matched applications to corresponding regions. The terminal for arranging the application icons comprises a first area classification module, a starting module, a statistic module, a matching module, an arranging module and a second area classification module. The method and terminal for arranging the application icons have the advantage that integral classification is carried out according to interface diversity and different regions of an interface.

Owner:YUNNEX TECH

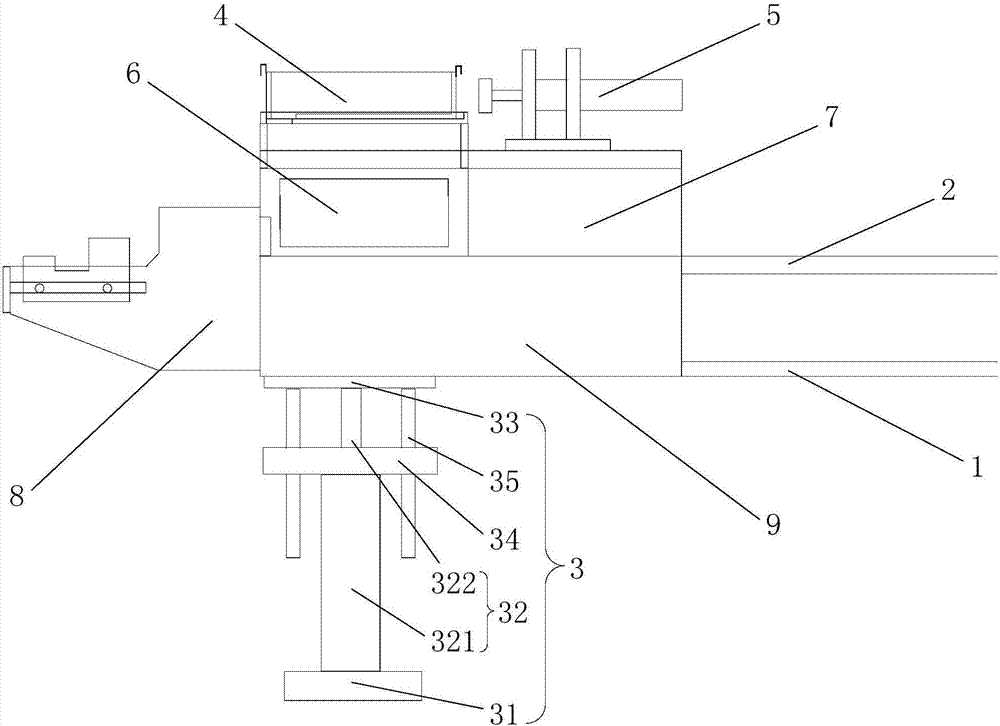

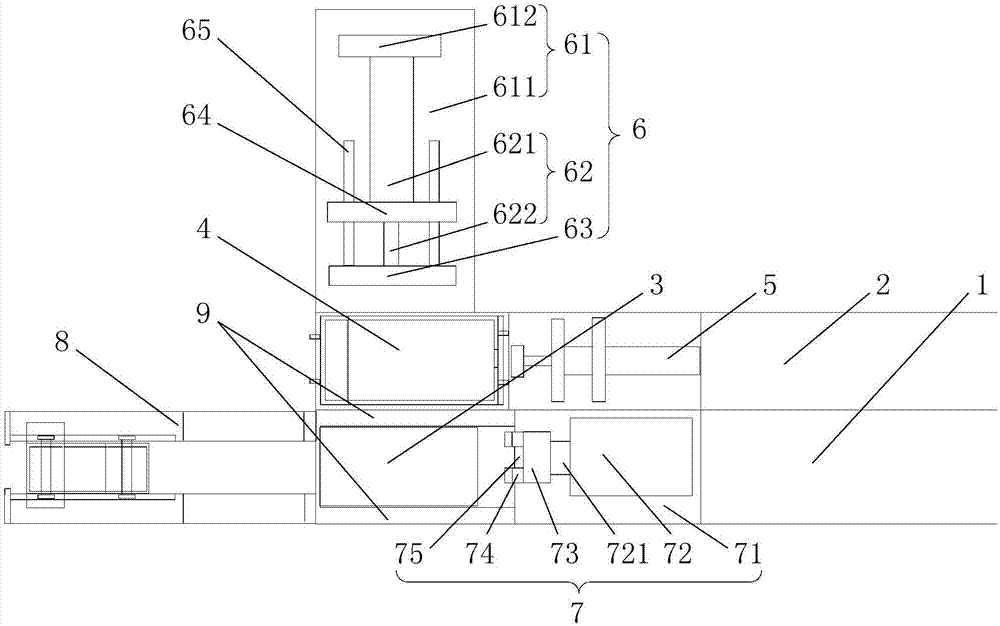

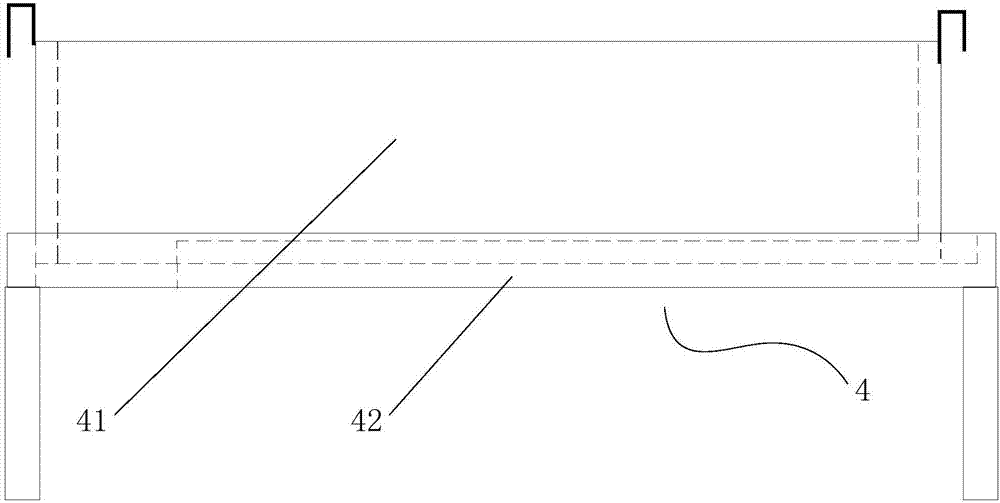

Car coupler buffer device assembling system and using method thereof

ActiveCN107116362AReasonably arrangedReasonable structureAssembly machinesCompression deviceMechanical engineering

The invention relates to a car coupler buffer device assembling system and a using method thereof. The system comprises a hook tail frame conveying line, a buffer unit conveying line arranged adjacent to the hook tail frame conveying line in parallel, a hook tail frame jacking device installed below a conveying plane of the operating end of the hook tail frame conveying line, a slave plate supporting device fixedly arranged above the conveying plane of the operating end of the buffer unit conveying line, a slave plate pushing device fixedly arranged above the conveying plane of the buffer unit conveying line, a buffer unit pushing device fixedly arranged on the side, opposite to the hook tail frame conveying line, of the operating end of the buffer unit conveying line, a compression device fixedly arranged above the conveying plane of the hook tail frame conveying line, and a car hook component supporting device fixedly connected with the operating end of the hook tail frame conveying line. The conveying plane of the buffer unit conveying line is at least one hook tail frame higher than the conveying plane of the hook tail frame conveying line. The operating end of the buffer unit conveying line is flush with the end face of the operating end of the hook tail frame conveying line.

Owner:CRRC QIQIHAR ROLLING CO LTD

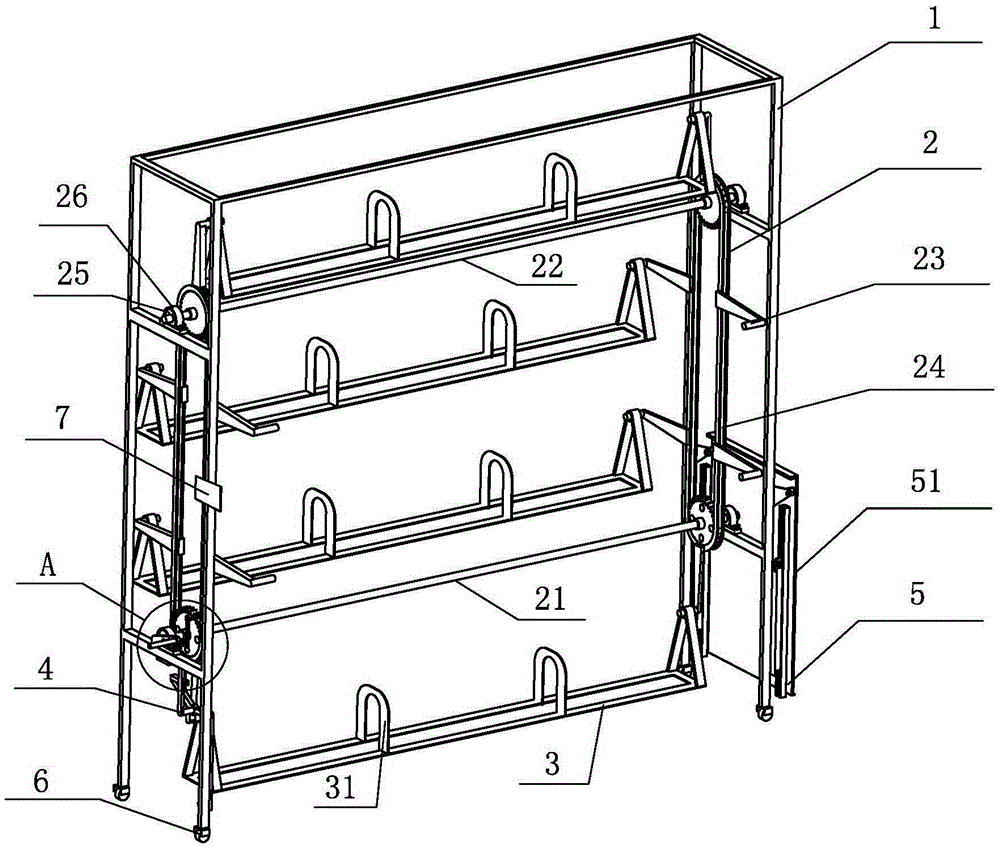

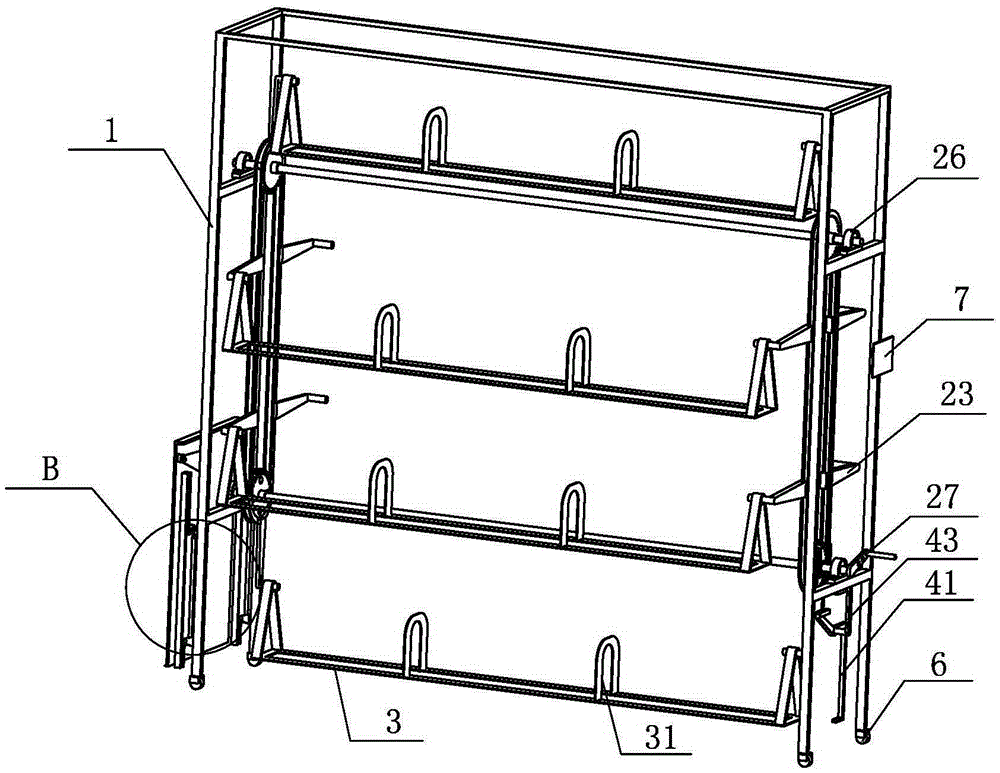

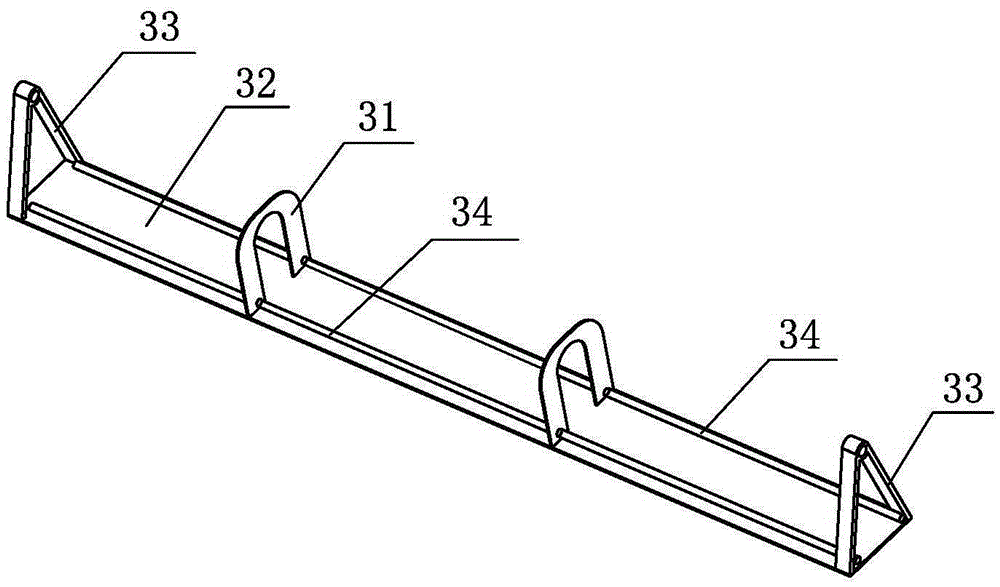

Vertical circulating drawing sorting-out combined shelf

Owner:STATE GRID SHANDONG ELECTRIC POWER

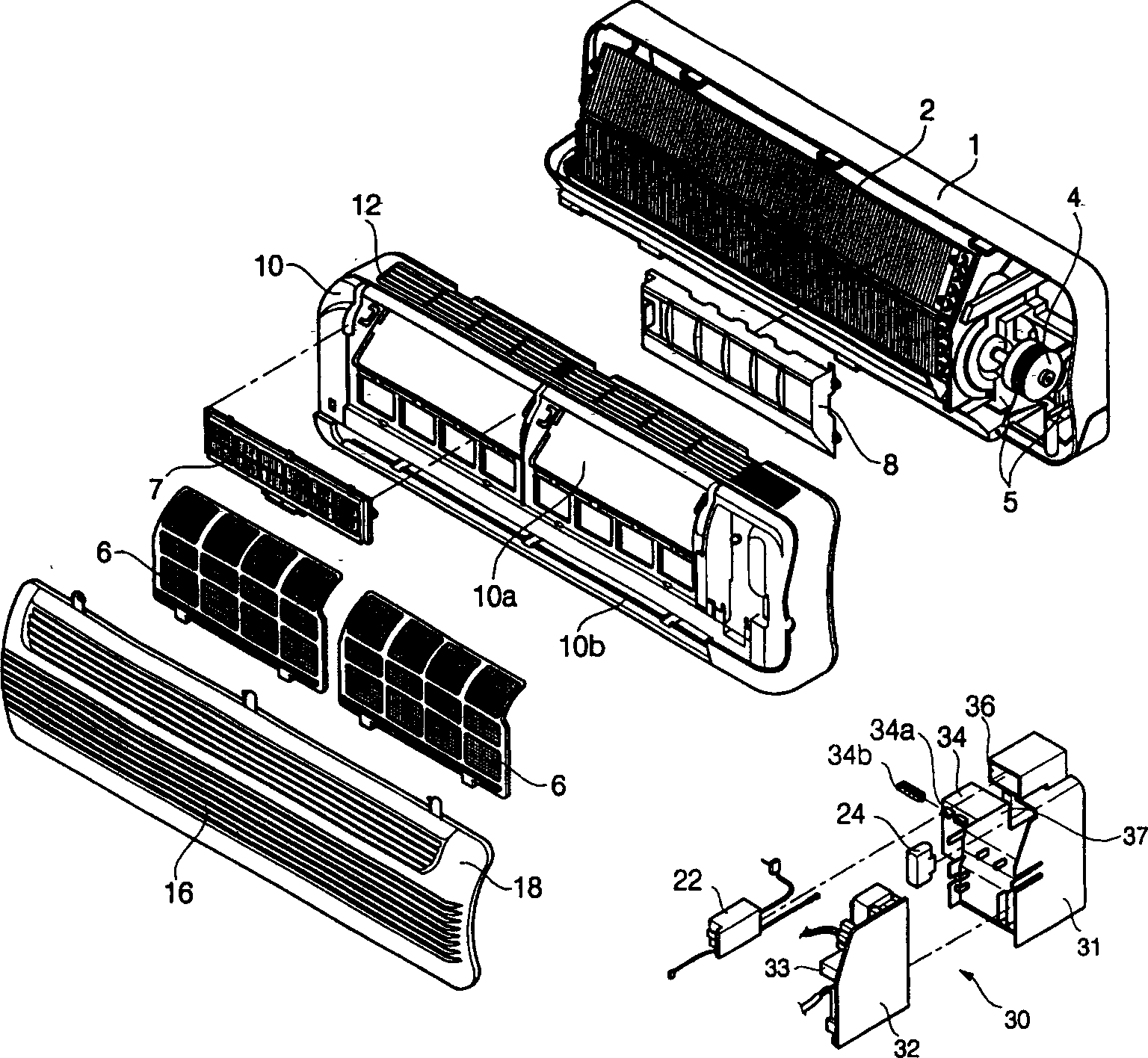

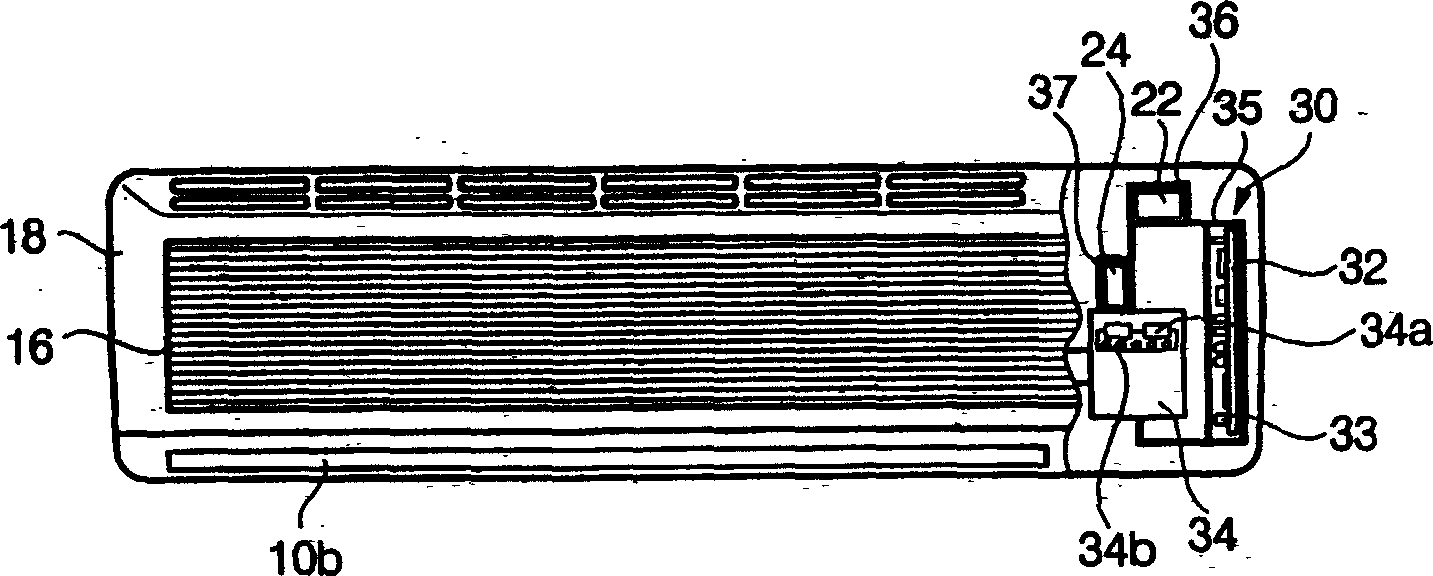

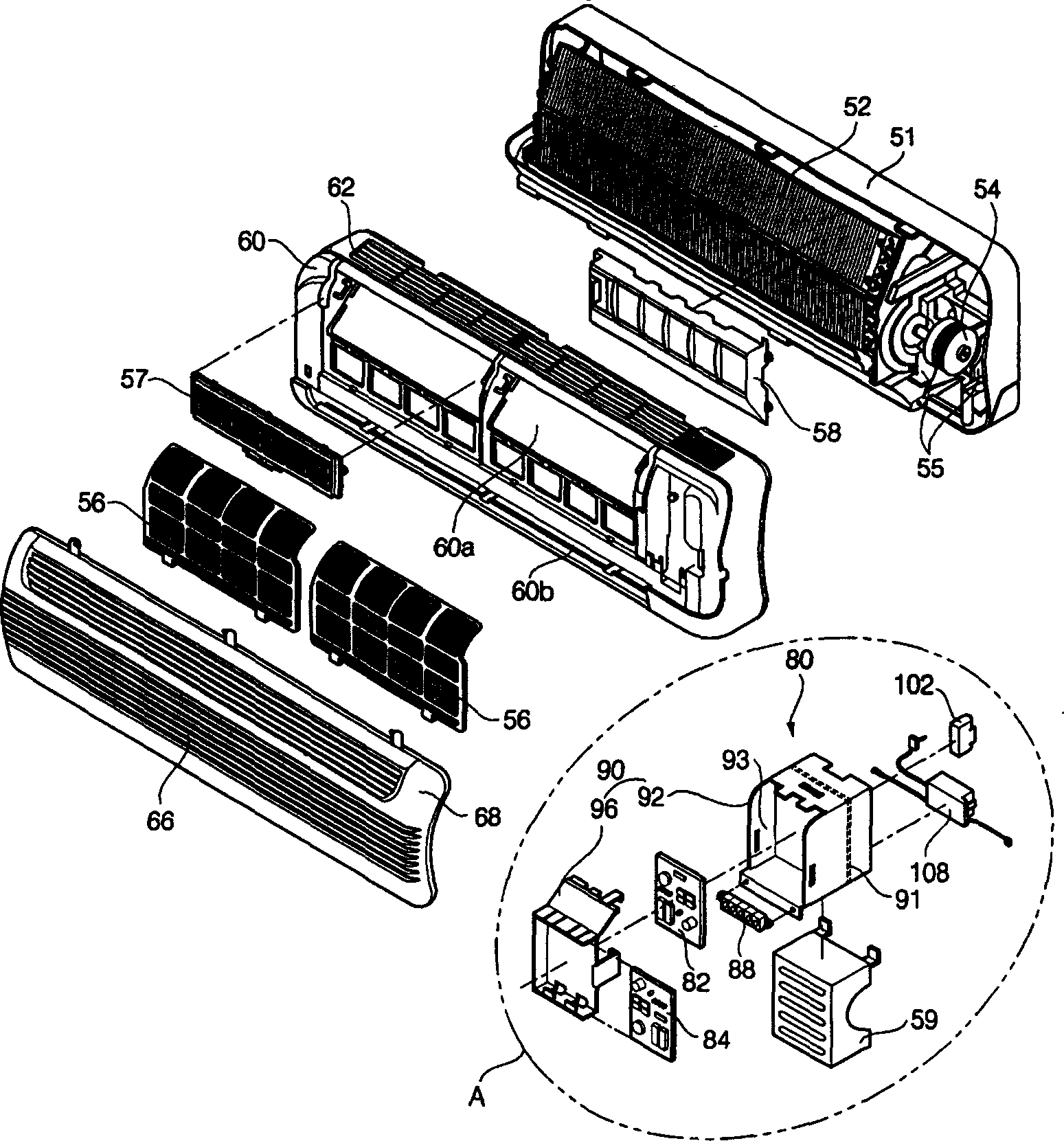

Control box assembly for air conditioner

InactiveCN1502900AReduce volumeEasy to assembleSpace heating and ventilation safety systemsLighting and heating apparatusElectronic componentAir conditioning

The present invention relates to a control box component of air conditioner. It includes control box casing, printed circuit base boards on which the electronic elements are mounted in the casing and mounting plate for mounting electronic device. In the invented control box component AC electric elements and DC electronic elements are respectively mounted on the different printed circuit base boards, and respectively mounted on the different positions. The capacitor and high-voltage generator are respectively mounted on the panels of different two sides in the rear portion of the control box.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

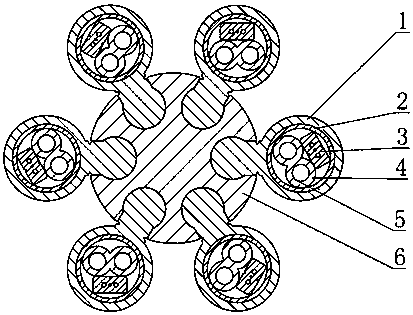

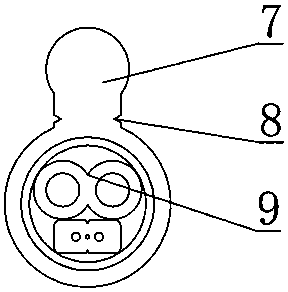

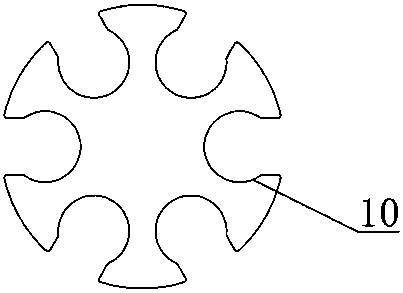

Indoor optical power composite cable capable of full-routing divergency

ActiveCN107945925AEasy to makeEasy to deployFlat/ribbon cablesPower cables including optical transmission elementsOptical powerEngineering

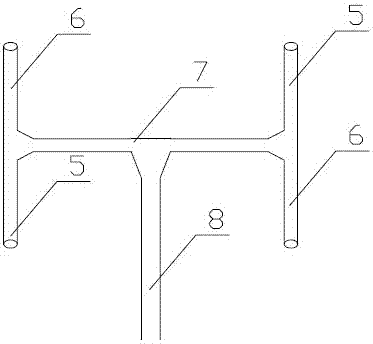

The invention relates to an indoor optical power composite cable capable of full-routing divergency. The indoor optical power composite cable is characterized by comprising a center bundling piece andbranched optical power composite cables connected with the center bundling piece, wherein inlaid connecting grooves are formed in the center bundling piece along the periphery at intervals; each branched optical power composite cable comprises an inlaid hoisting belt; the lower part of each inlaid hoisting belt is connected to an outer sheath; each outer sheath is internally coated with an optical cable and a metal wire; and the upper end of each inlaid hoisting belt is provided with a flange to be in inlaid connection with the corresponding inlaid connecting groove. The indoor optical powercomposite cable is convenient to manufacture and flexible to use and lay, different quantities and different lengths of the branched optical power composite cables can be installed according to actually laid conditions, and when the indoor optical power composite cable is used, diverged extraction can be realized as the circumstances may require from vertical wiring of vertical shafts to indoor laid installation, so that full-routing divergency is realized; the indoor optical power composite cable is reasonable in structure arrangement and high in protective performance and reliability, the bundling structure can protect the optical cables inside the vertical shafts and pipelines, the optical cables can be arranged in order, the space is saved, and the cable is convenient to lay and manage.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

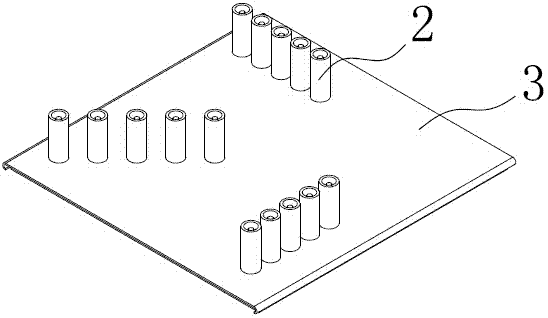

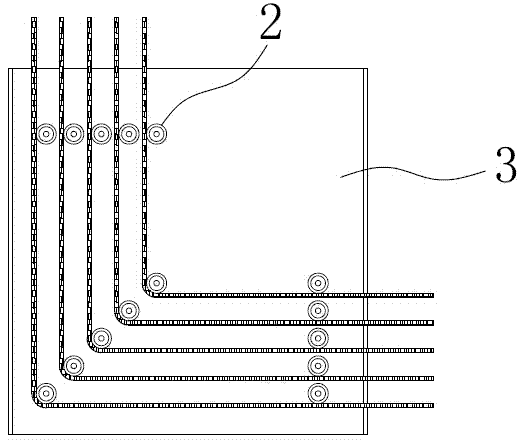

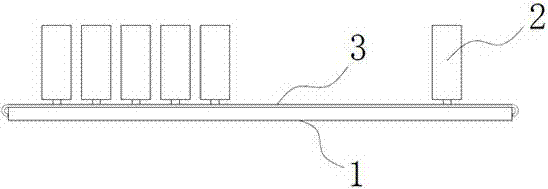

Yarn guide table

The invention discloses a yarn guide table comprising a bottom plate. There rows of comb teeth are arranged on the bottom plate. Every two rows of comb teeth have an included angle of 45 degrees. Each comb tooth comprises a support post and a rolling sleeve; the rolling sleeve is connected with the support post through a bearing. The yarn guide table is reasonable in structural design, rolling action of the bearings helps decrease static electricity generated by friction of yarns, the reasonable arrangement of the comb teeth in each row helps decrease tangling of the yarns, productivity is improved, safety hazards are avoided, and cost is lowered.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

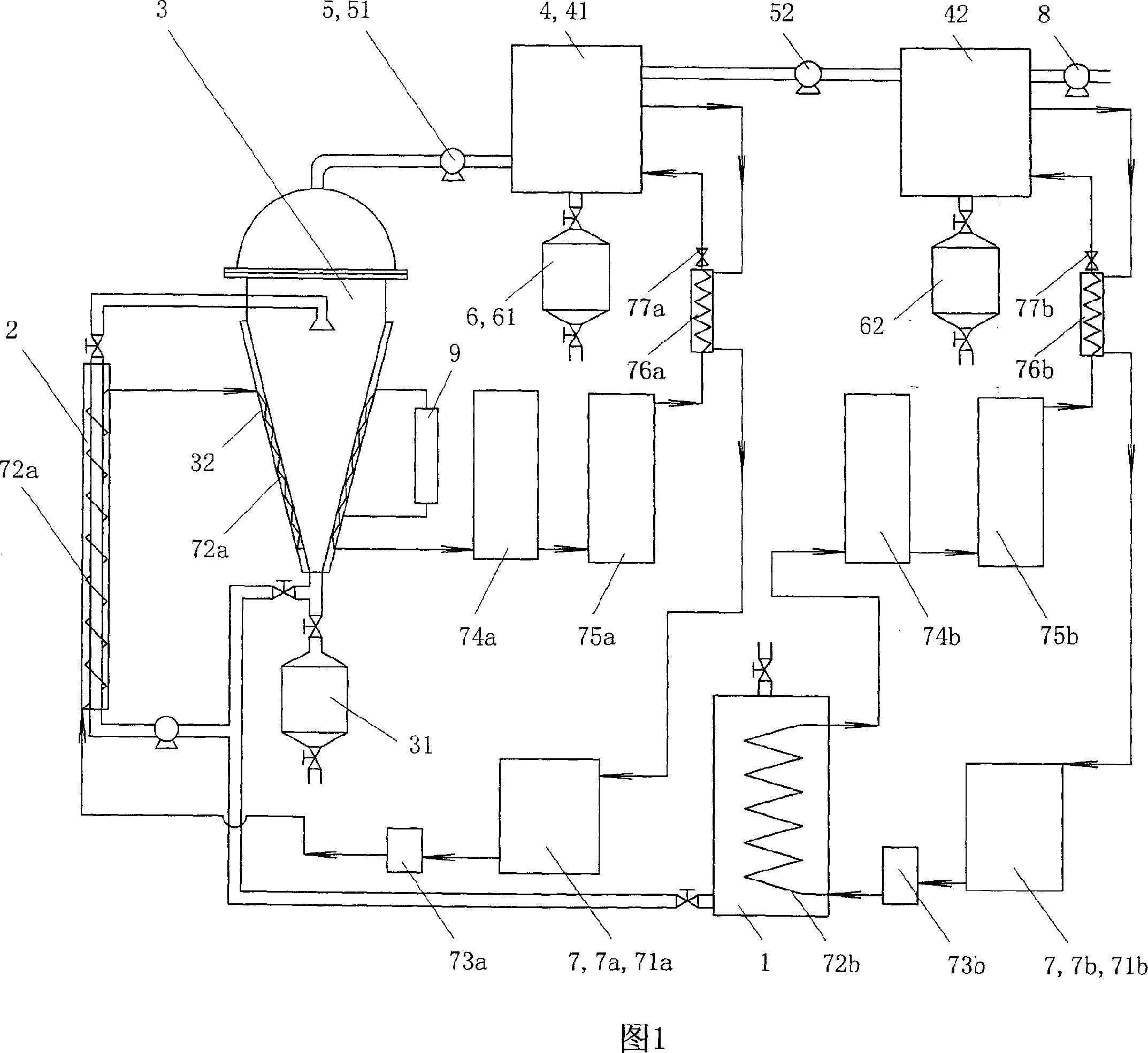

Fractional distillation apparatus

InactiveCN101024128AReasonably arrangedRapid pressure reductionBoiling apparatus with condenserDistillation separationRotary pumpVaporization

The invention relates to a rectify device. It has raw material cans,raw material pump and Jacket vacuum vaporization tank; Also with at least two vapor condensation catchers, Roots pumps set in the intake manifold of the vapor condensation catcher, and condensing collection link the bottom of the vapor condensation catcher, each of the vapor condensation catcher with the refrigerator, heat exchangers and the expansion valve composed cooling circulatory system, the out trachea of first-class vapor condensation catcher connected with the Roots pump of second-class vapor condensation catcher, out trachea of the final one vapor condensation catcher connected with rotary pump, heat exchanger in the different cooling circulatory system installed in a vacuum evaporation tank jacket or installed in raw materials in the tank. This invention's advantages are lower power consumption, simple structure, smaller volume, the distilled production with many varieties, high purity.

Owner:李志平 +1

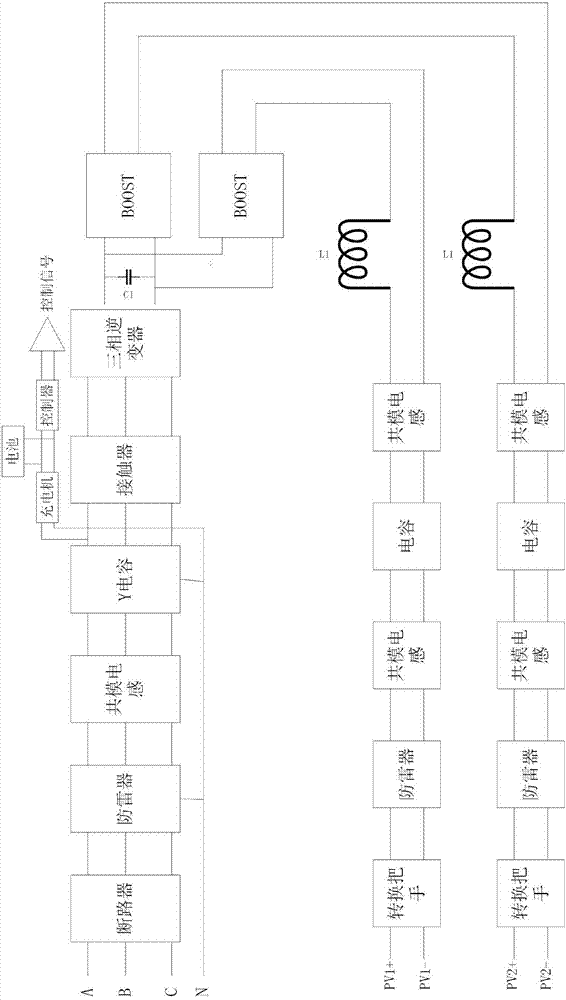

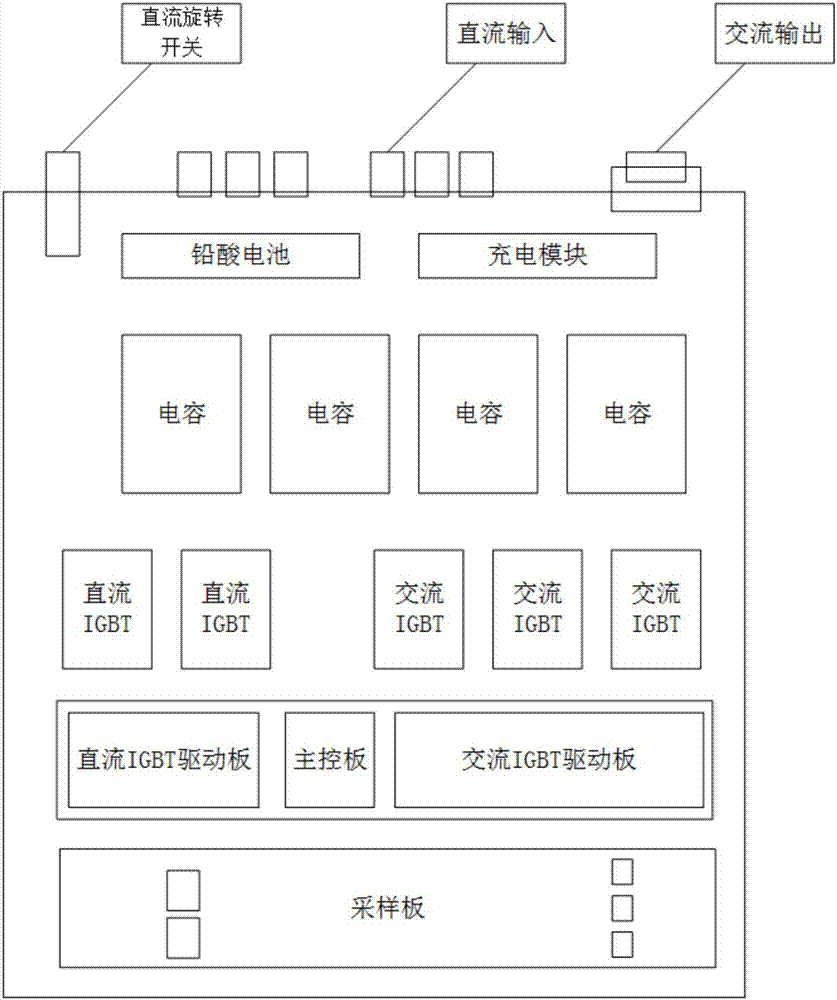

Photovoltaic inverter

PendingCN107040148AAchieve high efficiencyReasonably arrangedConversion constructional detailsPhotovoltaic energy generationPower inverterMiniaturization

The present invention provides a photovoltaic inverter. The photovoltaic inverter comprises a direct current interface piece, a power module, a capacitor module, an IGBT module, a power panel and a sampling plate. According to the internal structure arrangement of the photovoltaic inverter, the sizes of required elements are reasonably selected on the premise of satisfying the functions of the photovoltaic inverter, optimization arrangement of each part is performed in the inverter according to the size of each element, the internal devices are reasonably arranged, the heat radiation efficiency is high, and a fan is not needed, so that the installation cost and the maintenance cost are reduced, and the high efficiency and the miniaturization of the photovoltaic inverter are realized.

Owner:北京群菱能源科技有限公司

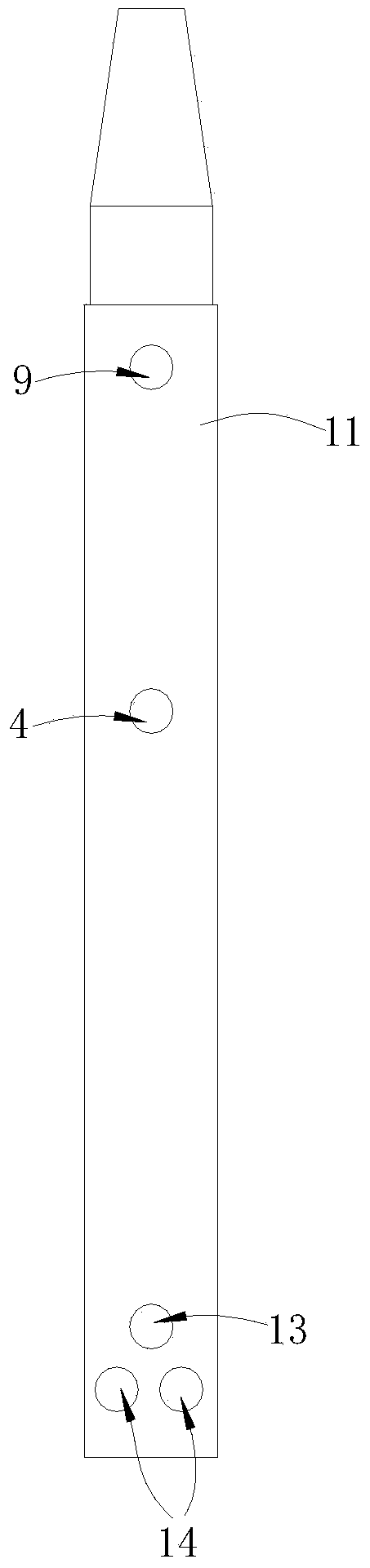

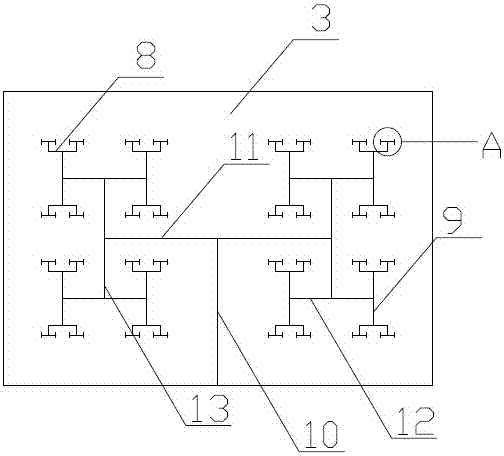

Vertically-blown Ba-wu flute wider in range

The invention provides a vertically-blown Ba-wu flute wider in range. A main pipe is provided with a reed and ten pressed sound holes. Seven pressed sound holes, namely, the first pressed sound hole, the second pressed sound hole, the third pressed sound hole, the fifth pressed sound hole, the sixth pressed sound hole, the seventh pressed sound hole and the eighth pressed sound hole, are distributed in the front face of the main pipe. A little-finger bass pressed hole is additionally formed in the side face of the lower portion of the main pipe. Two pressed sound holes, namely, the fourth pressed sound hole and the ninth pressed sound hole, are distributed in the back face of the main pipe. The interval of the fourth pressed sound hole is two degrees higher than that of the third pressed sound hole, and the interval of the fourth pressed sound hole is also two degrees higher than that of the fifth pressed sound hole. According to the vertically-blown Ba-wu flute, the ten sound holes can be controlled by ten fingers, the aim of widening the range can be achieved without adding control keys, the unique glissando effect of the national wind music can be achieved through playing, modulation is easier due to the interval arrangement relation of the vertically-blown Ba-wu flute, the playing range is expanded to 15 degrees or 16 degrees from the original 11 degrees, and therefore the requirements of players are better met, and the music expressive force of the vertically-blown Ba-wu flute is greatly enriched.

Owner:李凯

Micro-channel reactor for producing nano sulfate

InactiveCN107281983AAvoid reunionWell mixedChemical/physical/physico-chemical microreactorsChemical reactionSulfate

The invention relates to a micro-channel reactor for producing nano sulfate and belongs to the technical field of chemical reaction equipment. The micro-channel reactor provided by the invention has the benefits that through the arrangement of a three-layer structure and a multistage reaction unit, feeding is more accurate, and reaction materials are more uniformly mixed, and the laminar flow phenomenon of feed liquid occurring in the collision reaction process is overcome, so that the reaction is closer to a flow state, the contact in the reaction process is more full, and the reaction is more thorough; the re-agglomeration of nano sulfate generated by collision reaction can be effectively avoided, so that a product is kept in a nanometer form and is uniform in particle size, and further, a high-quality nano sulfate product is prepared.

Owner:YIBIN GRACE GROUP CO LTD

Continuous ultrasonic emulsification device for water-based resin and using method of continuous ultrasonic emulsification device

InactiveCN113181784AWell mixedSolving Mixing ProblemsShaking/oscillating/vibrating mixersTransportation and packagingUltrasonic emulsificationUltrasonic generator

The invention provides a water-based resin continuous ultrasonic emulsification device and a using method of the continuous ultrasonic emulsification device. The device comprises an emulsification cavity and a premixing cavity, wherein a first feeding port and a second feeding port are formed in the top of the premixing cavity, a material mixing and stirring device is arranged in the premixing cavity, a discharging port in the bottom of the premixing cavity is connected with a feeding port of the emulsification cavity through a feeding pump, energy-gathered ultrasonic generators are arranged at the top and the bottom of the emulsification cavity, ultrasonic probes of the energy-gathered ultrasonic generators extend into the emulsification cavity, a high-speed dispersion machine is arranged at the top of the emulsification cavity, a dispersion disc of the high-speed dispersion machine is arranged in the emulsification cavity, multiple sets of divergent ultrasonic generators are arranged on the outer wall of the emulsification cavity, and a discharge port valve is arranged at the discharge port of the emulsification cavity. According to the invention, a violent effect between particles is formed between two materials by utilizing a mechanical effect and a cavitation effect of ultrasonic waves, the emulsification process of the materials is completed in a very short time, the continuity of an ultrasonic emulsification device is improved, and the yield and the output efficiency of an emulsified product are improved.

Owner:SHAANXI UNIV OF SCI & TECH

A spiral pipe production line

Owner:河北德威钢管有限公司

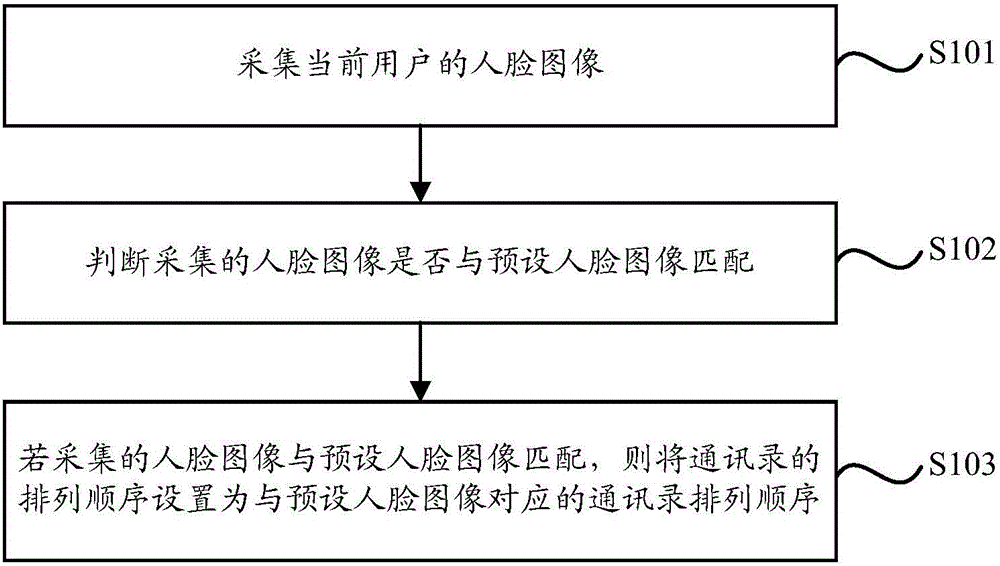

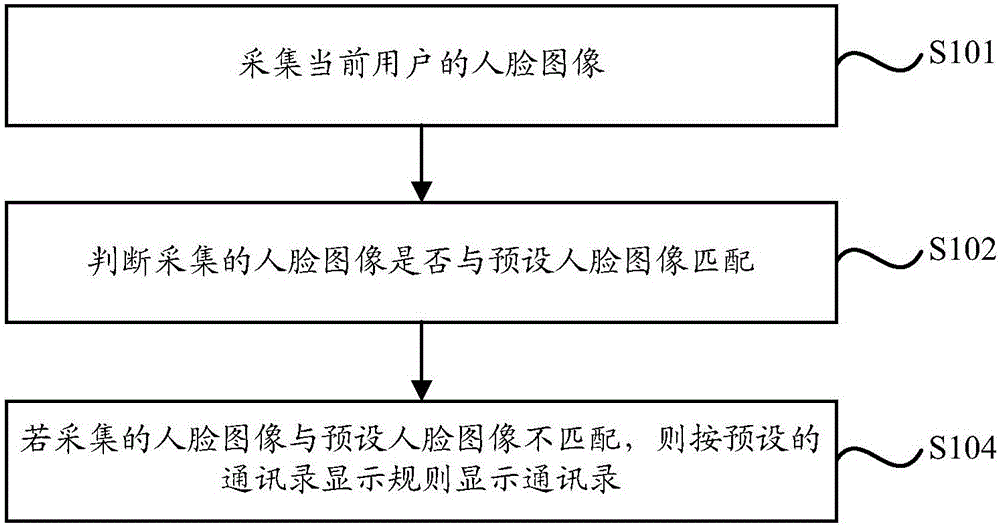

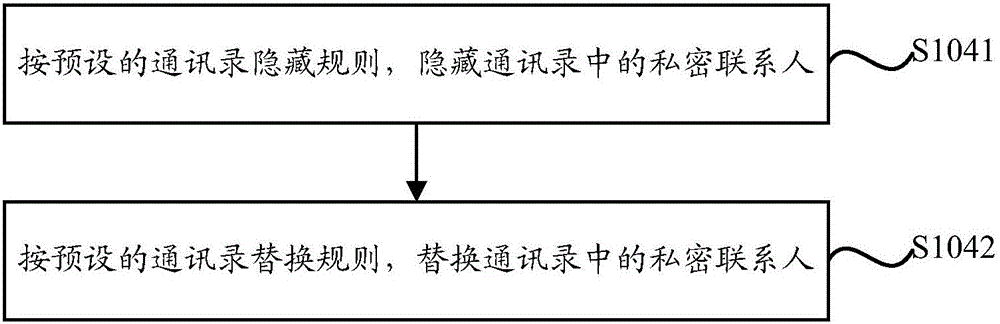

Terminal and processing method and system thereof

The invention discloses a terminal and a processing method and system thereof. The processing method comprises that a face image of a present user is collected; whether the face image matches a preset face image is determined; and if YES, the sequence of a contact list is set to be ordered according to a contact list ordering rule corresponding to the preset face image. The identity of the present user is identified by matching the face image of the present user with the preset face image, the ordering sequence of the contact list is set according to the user identity, the sequence of the contact list of the terminal changes with present users, the present user can use the contact list of the terminal more conveniently, and the user experience is improved.

Owner:TCL COMM NINGBO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com