A spiral pipe production line

A production line and spiral pipe technology, applied in the field of new spiral pipe production lines, can solve the problems of long production cycle, cost reduction, and inability to accurately control the diameter and accuracy of steel pipes, and achieve the effect of liberating manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

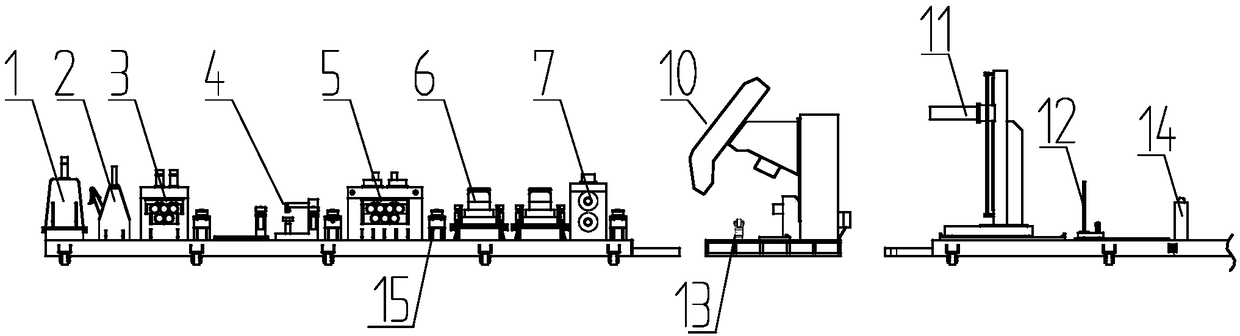

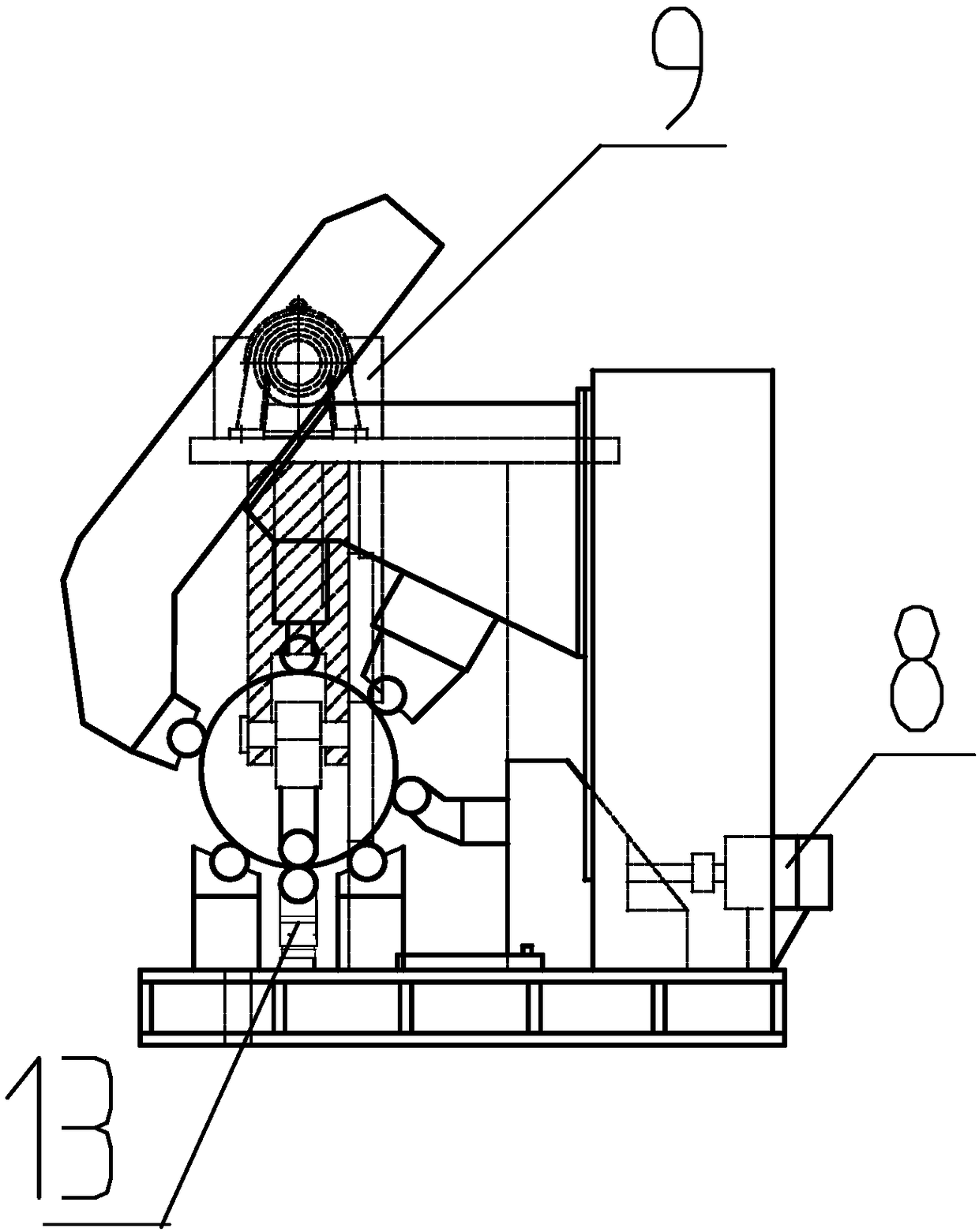

[0040] The following is attached Figure 1-8, the present invention is further described:

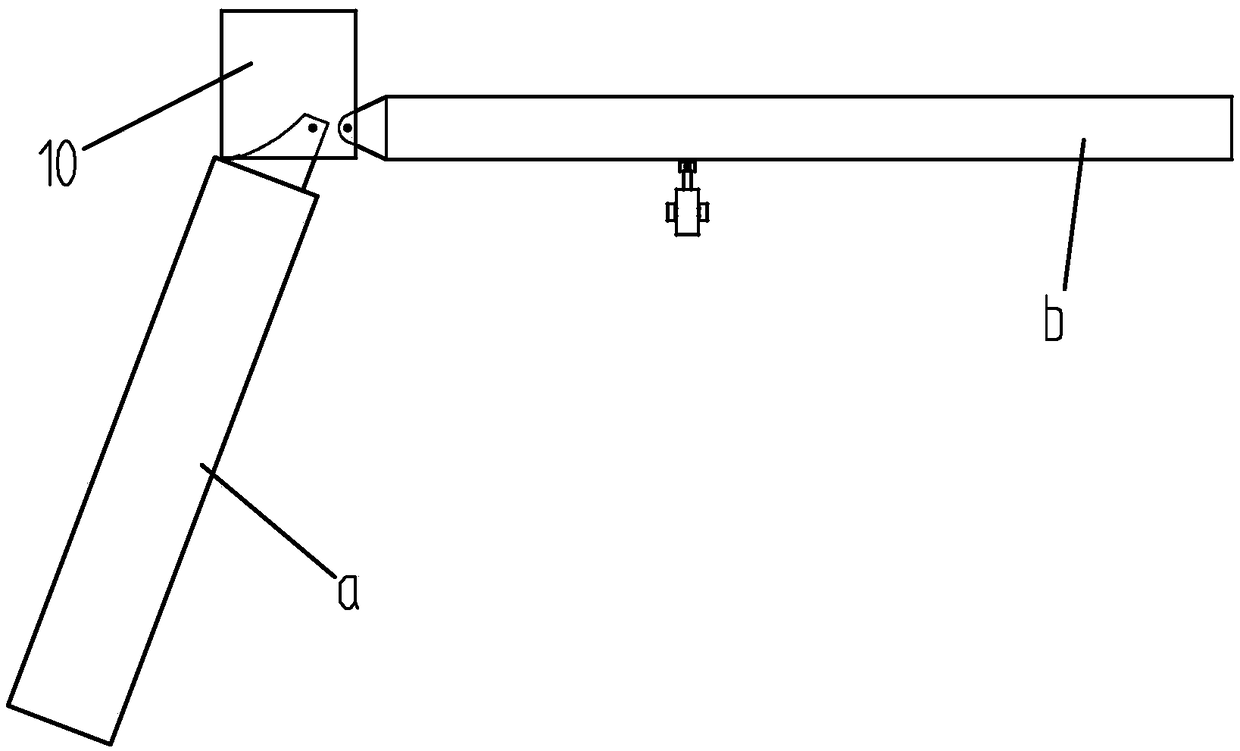

[0041] Such as figure 1 , figure 2 As shown, a novel spiral pipe production line is provided, which includes successively connected front axle forming frames a, molding equipment 10, and rear axle forming frames b, with clips between the front axle forming frames a and the rear axle forming frames b. horn;

[0042] On the front axle forming frame a, there are arranged in sequence,

[0043] The uncoiling device 1 is used to rotate and limit the coiled plate and also guide the coiled plate joint to the subsequent device;

[0044] The shovel head device 2 is used to preliminarily flatten the arc-shaped head of the coiled plate and transport it to subsequent equipment.

[0045] Coarse flattening device 3, used to flatten the coiled plate for the first time;

[0046] The quick docking device 4 is used to quickly dock the tail end of the preceding steel plate and the head end of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com