Micro-channel reactor for producing nano sulfate

A technology of microchannel reactor and sulfate, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve incomplete reaction, poor product quality, raw material mixing Inhomogeneity and other problems, to avoid re-agglomeration, complete reaction, accurate feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

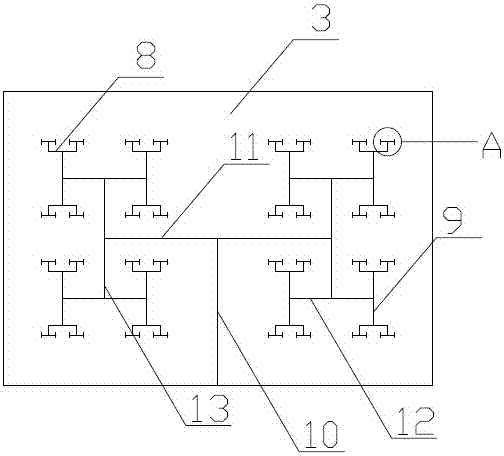

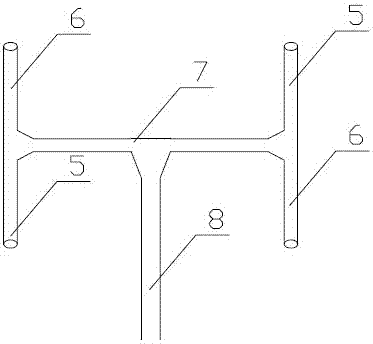

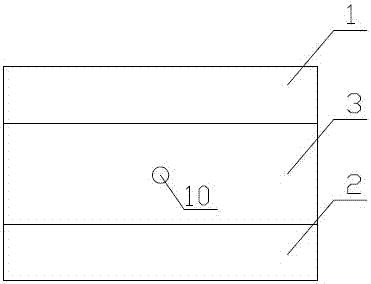

[0040] A microchannel reactor for producing nano-sulfate, comprising an upper feed layer 1, a lower feed layer 2 and a middle reaction layer 3; both the upper feed layer 1 and the lower feed layer 2 are provided with feed holes 4; The middle reaction layer 3 is a network branch structure, and the chloride salt feed channel 5 is communicated with the sodium sulfate feed channel 6 to form a feed unit, and the two described feed units are arranged oppositely, and pass through the primary channel at the same time. 7 is connected, and the feeding unit and the primary channel 7 form a primary reaction unit; the two primary reaction units are arranged opposite each other, and are communicated through the secondary channel 8 at the same time to form a secondary reaction unit; Said secondary reaction units are relatively set up and communicated through tertiary channel 9 at the same time to form a tertiary reaction unit; according to the above composition method, every two N-stage react...

Embodiment 2

[0044] A microchannel reactor for producing nano-sulfate, comprising an upper feed layer 1, a lower feed layer 2 and a middle reaction layer 3; both the upper feed layer 1 and the lower feed layer 2 are provided with feed holes 4; The middle reaction layer 3 is a network branch structure, and the chloride salt feed channel 5 is communicated with the sodium sulfate feed channel 6 to form a feed unit, and the two described feed units are arranged oppositely, and pass through the primary channel at the same time. 7 is connected, and the feeding unit and the primary channel 7 form a primary reaction unit; the two primary reaction units are arranged opposite each other, and are communicated through the secondary channel 8 at the same time to form a secondary reaction unit; Said secondary reaction units are relatively set up and communicated through tertiary channel 9 at the same time to form a tertiary reaction unit; according to the above composition method, every two N-stage react...

Embodiment 3

[0047] A microchannel reactor for producing nano-sulfate, comprising an upper feed layer 1, a lower feed layer 2 and a middle reaction layer 3; both the upper feed layer 1 and the lower feed layer 2 are provided with feed holes 4; The middle reaction layer 3 is a network branch structure, and the chloride salt feed channel 5 is communicated with the sodium sulfate feed channel 6 to form a feed unit, and the two described feed units are arranged oppositely, and pass through the primary channel at the same time. 7 is connected, and the feeding unit and the primary channel 7 form a primary reaction unit; the two primary reaction units are arranged opposite each other, and are communicated through the secondary channel 8 at the same time to form a secondary reaction unit; Said secondary reaction units are relatively set up and communicated through tertiary channel 9 at the same time to form a tertiary reaction unit; according to the above composition method, every two N-stage react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com