Precoated sand production line

A production line and technology of coated sand, which is applied in casting molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. Reasonable, excellent product quality, good lamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

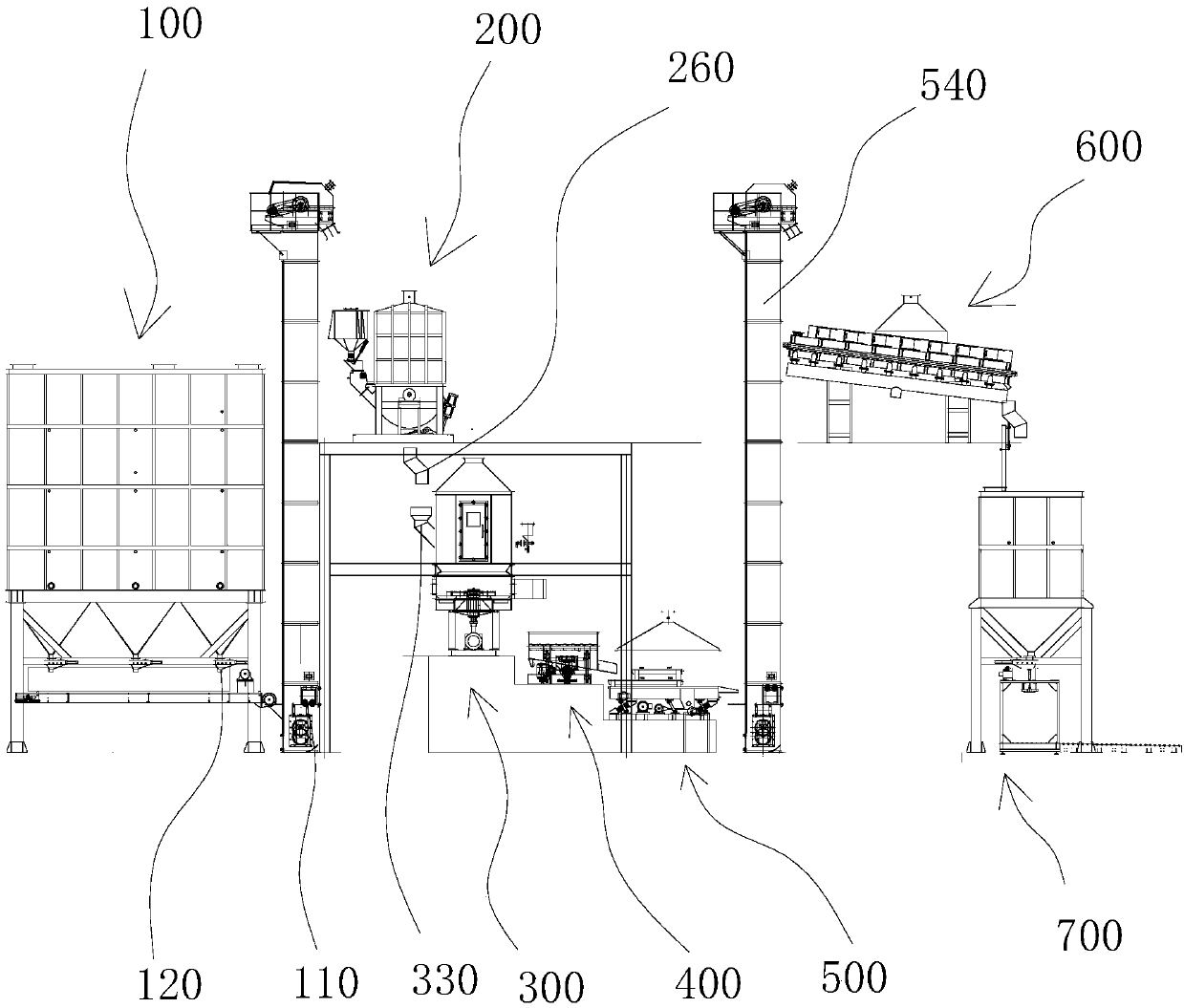

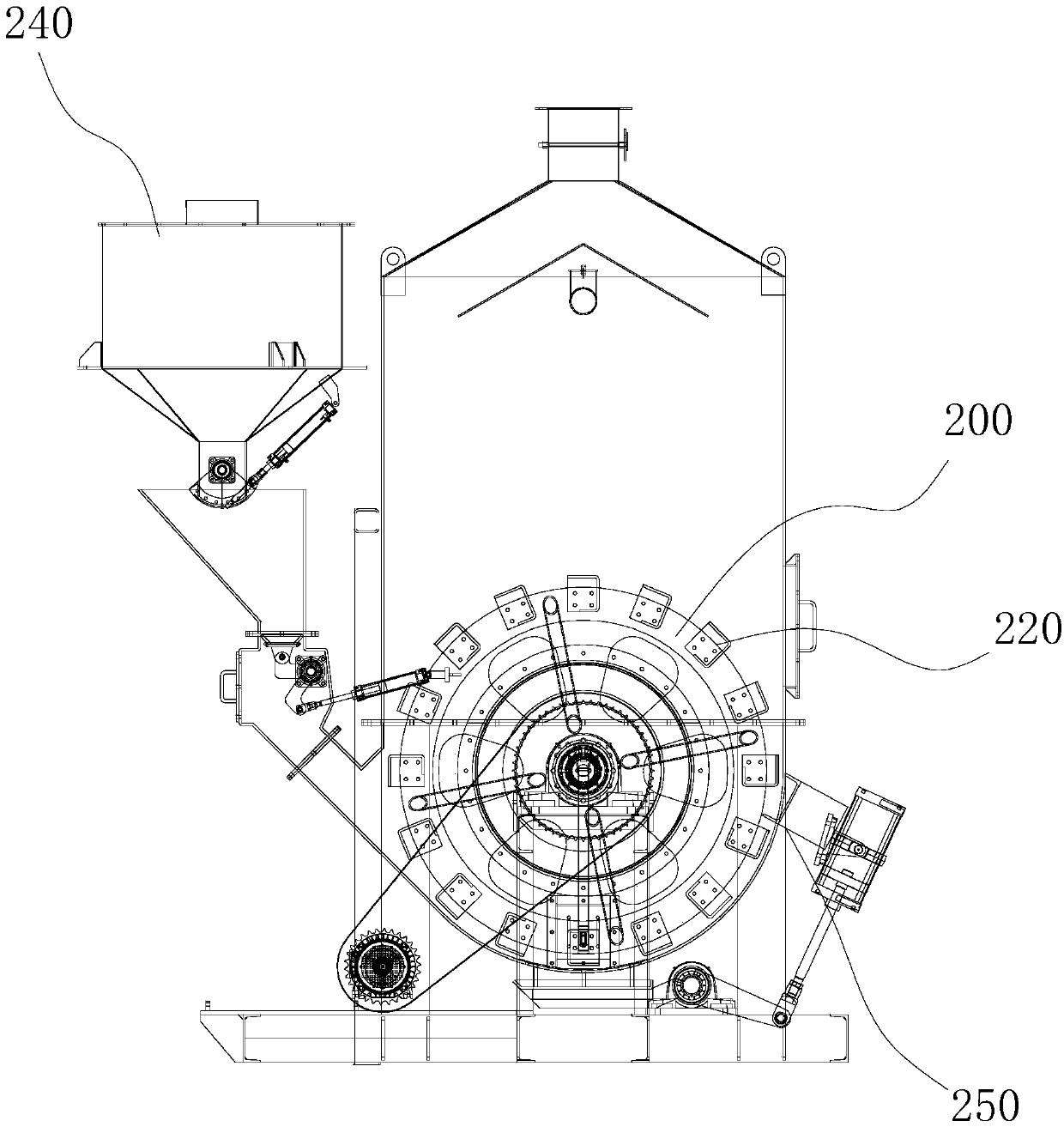

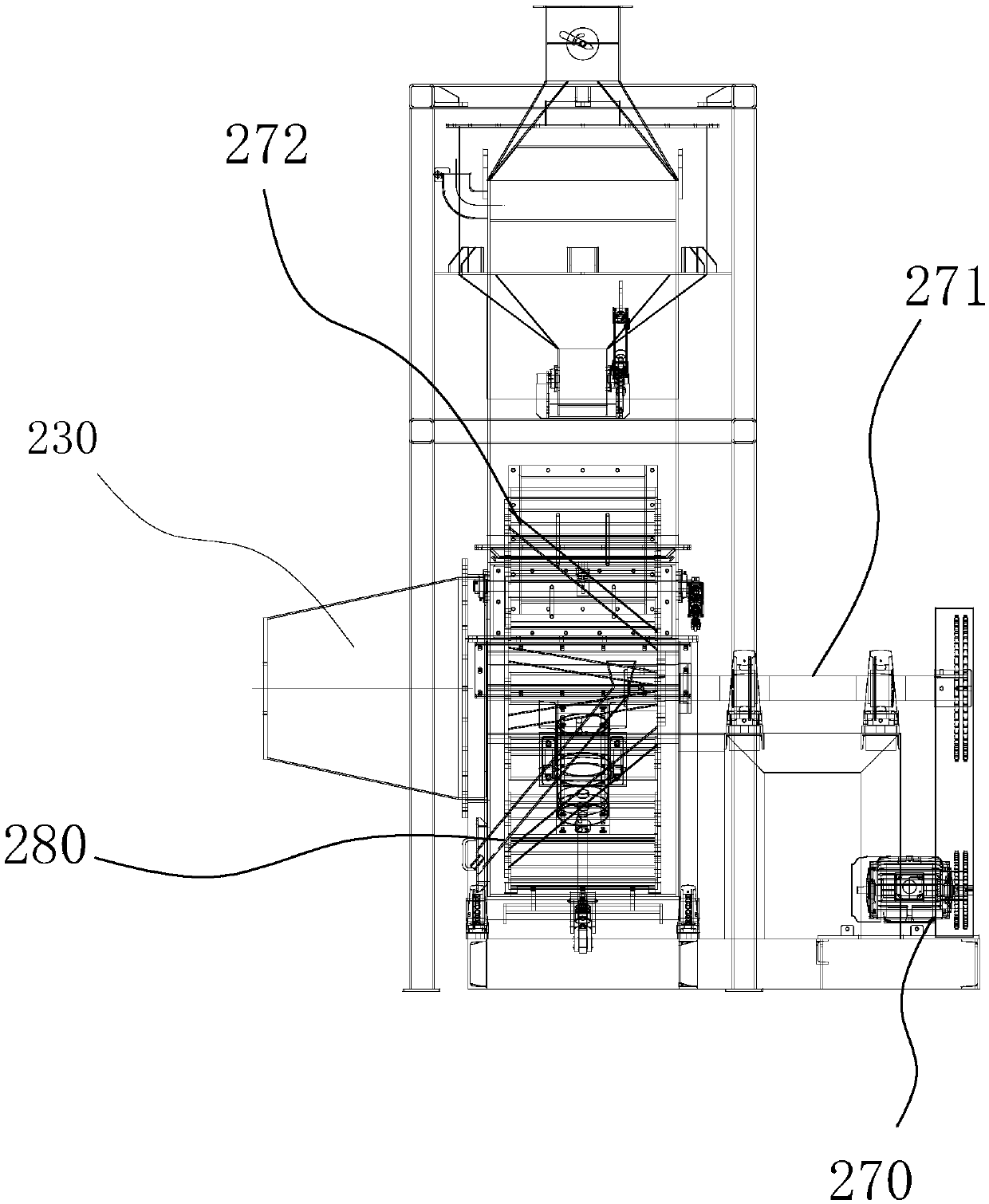

[0033] Such as figure 1 figure 2 As shown, a coated sand production line includes a raw sand silo 100, a heating machine 200, a mixer 300, a shaker 400 and a finished product silo, and a feed is provided between the raw sand silo 100 and the heating machine 200 The bucket elevator 110 and the heating machine 200 are provided with a pair of stirring wheels 210 inside. Several sand mixing buckets 220 are uniformly arranged on the edge of the stirring wheels 210. The rotation of the stirring wheels 210 drives the sand mixing buckets 220 to move in the circumferential direction. The burner 230 that outputs heat to the center of rotation of the stirring wheel 210, the kneader 300 is arranged under the heating machine 200, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com