Fractional distillation apparatus

A rectification and vacuum technology, which is applied in the direction of boiling devices with condensers, distillation separation, chemical instruments and methods, etc., can solve the problems of large energy consumption and large volume, and achieve low energy consumption, reasonable arrangement and low manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

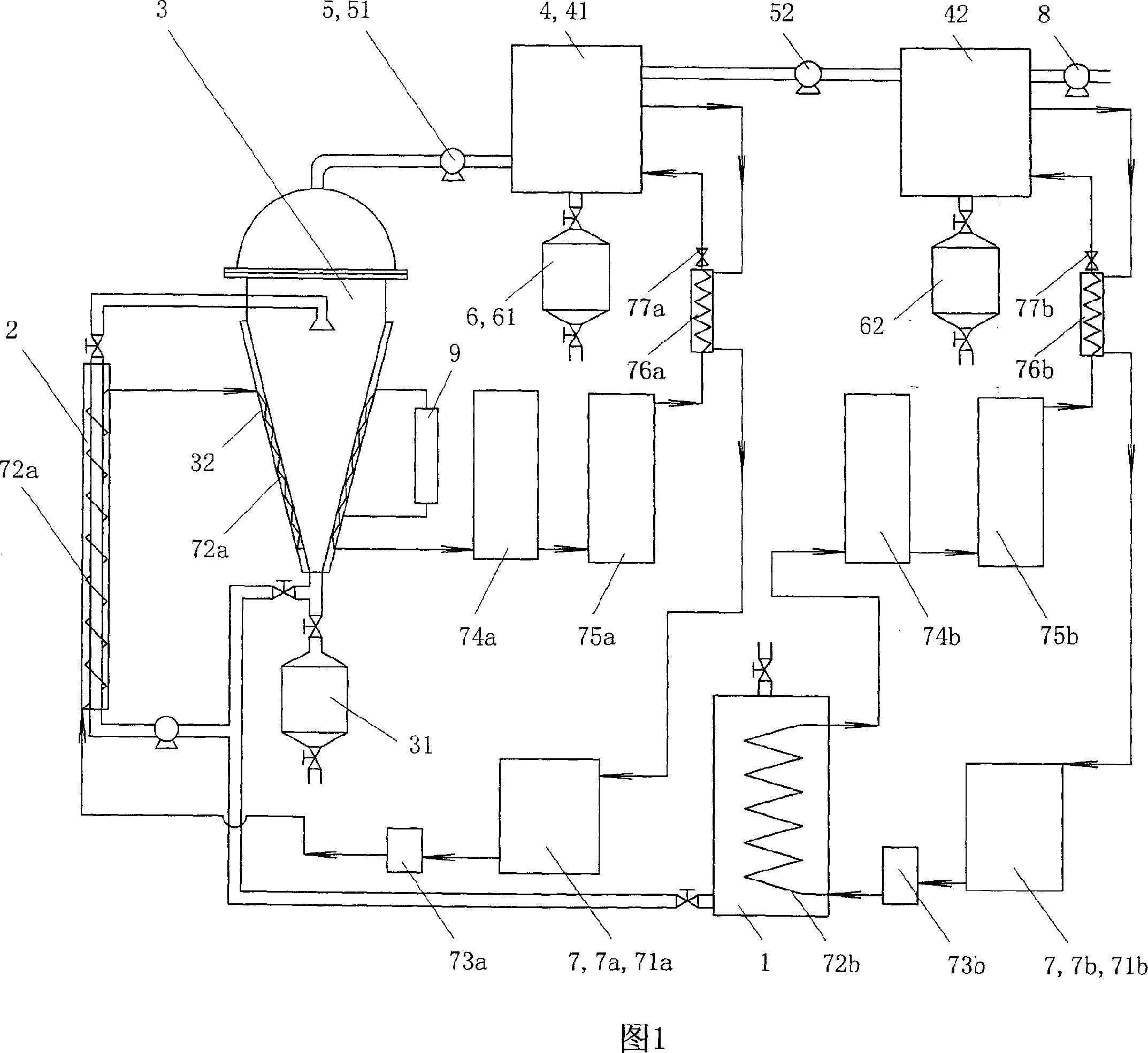

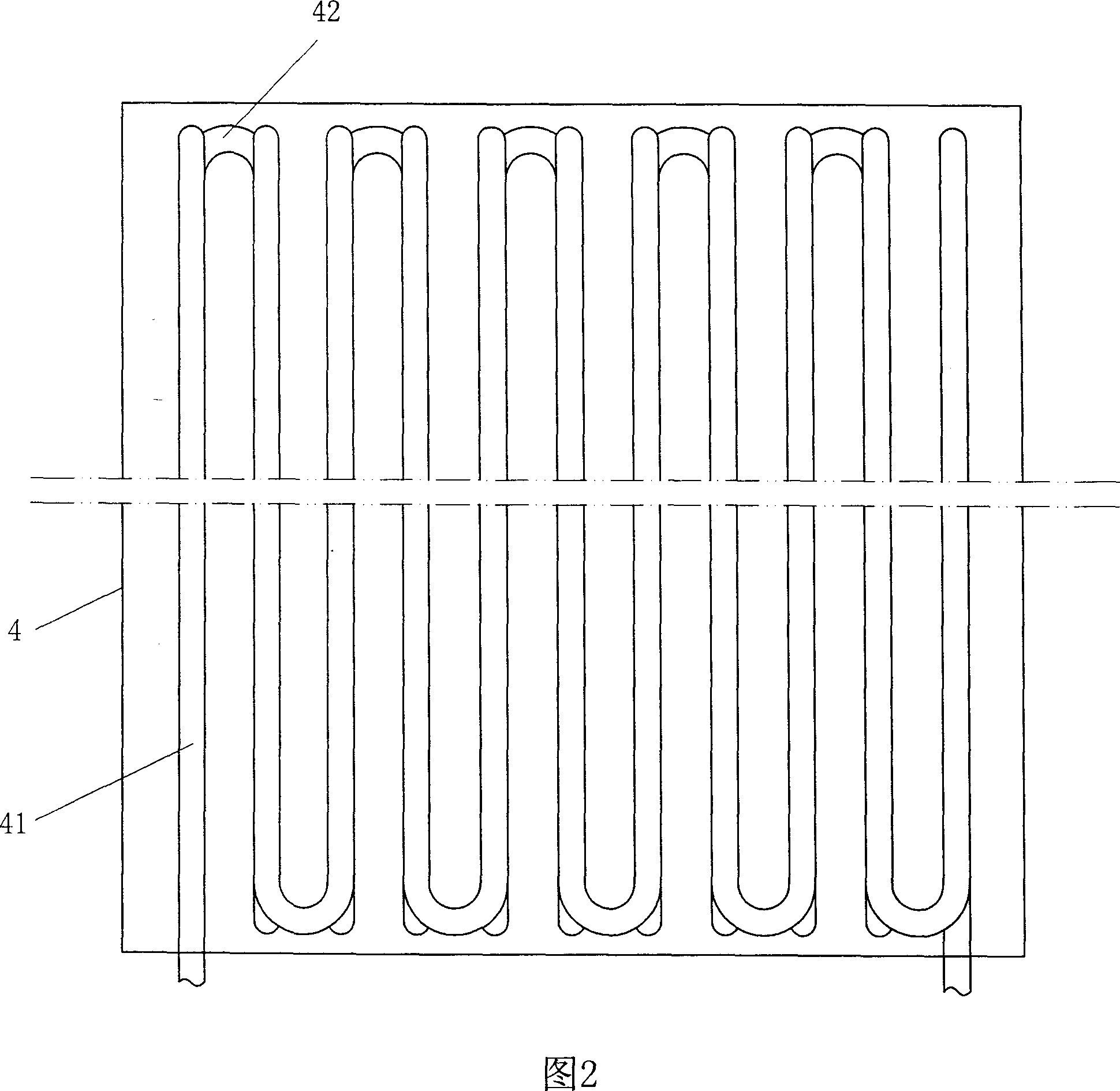

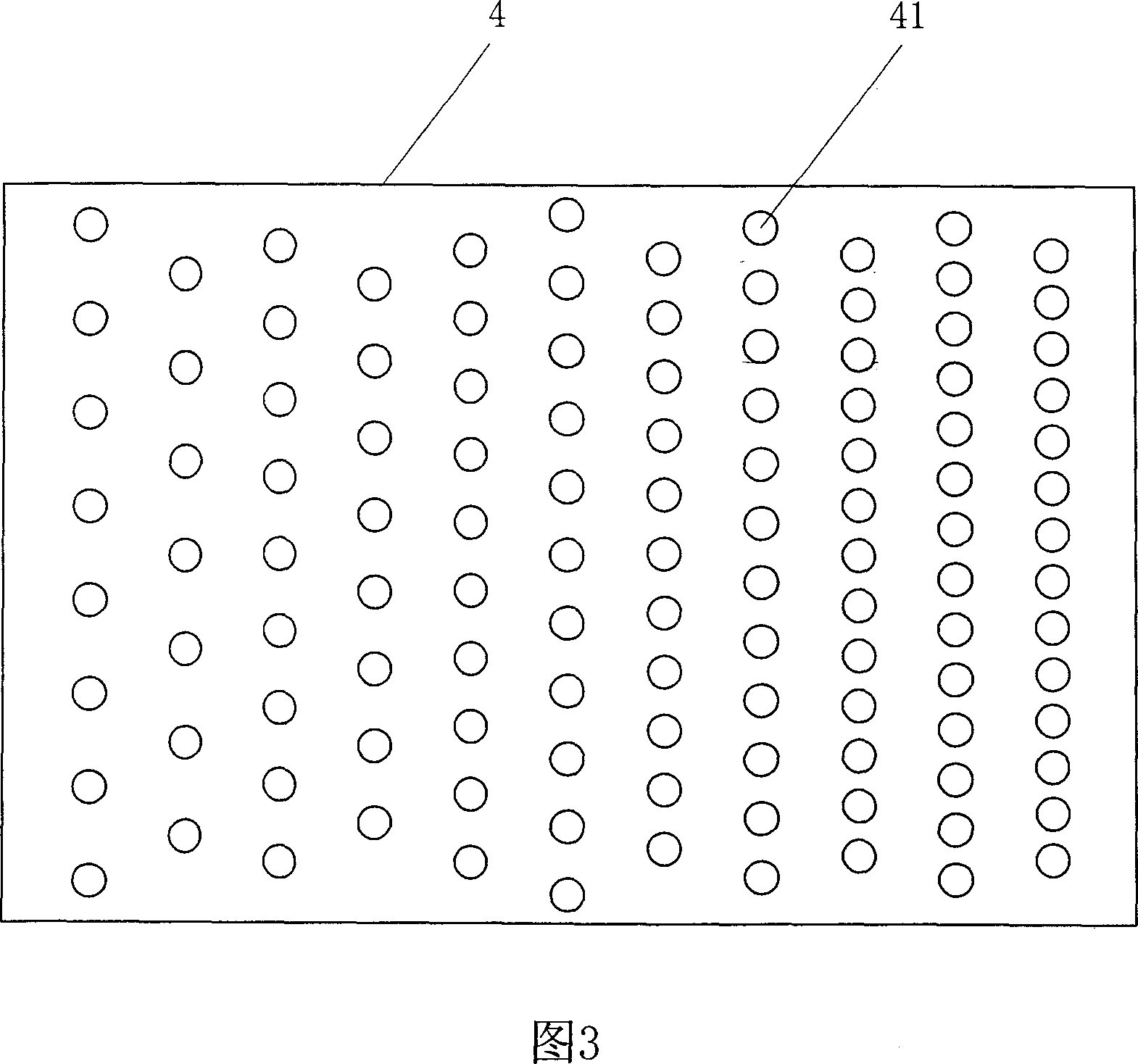

[0021] See Fig. 1, the present invention is a kind of rectifying device, has raw material tank 1, raw material pump and jacket type vacuum vaporizer 3, the bottom of jacket type vacuum vaporizer 3 is provided with heavy component collection tank 31, and jacket 32 An auxiliary heating system 9 is provided, and a sleeve pipe 2 is arranged on the feed pipe of the vacuum vaporization tank 3; A Roots pump 5 is provided, and a condensate collector 6 is connected to the bottom, and each vapor condensation catcher 4 is connected with a refrigerator 71, an oil fraction 73, a heat exchanger 72, an air cooler 74, a liquid storage tank 75, and a subcooler 76 and expansion valve 77 form the cooling circulation system 7. The subcooler 76 is a heat exchange device with a shell and a coil pipe arranged in the shell. The shell and the coil pipe have an inlet and an outlet respectively. The above-mentioned first stage steam The outlet pipe of the gas condensation catcher 41 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com