Manufacturing method for fertilizer pulping machine

A manufacturing method and mechanical technology, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of incomplete crushing and emulsification, affecting fertilizer utilization rate, low production efficiency, etc., and achieves simple structure, high production efficiency, The effect of fast emulsification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

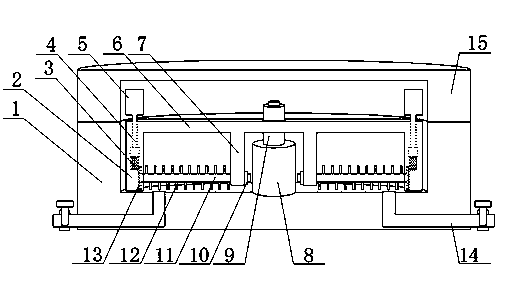

[0022] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a schematic cross-sectional structure diagram of the present invention.

[0023] A kind of manufacturing method of fertilizer beating machine of the present invention, wherein, comprises the following steps: A, use brick, stone, concrete to build beating pool, build beating pool into high 1.6m, diameter is the circular shape of 8-10m middle part depression The structure uses expansion screws to fix the rotary motor to the center of the bottom of the beating pool, and the output shaft of the rotary motor is connected to the fixed rotating shaft. The length of the rotating shaft is 60cm and the diameter is 10cm. , the middle part of the rotating shaft is further socketed and fixed with a rotating frame. The rotating frame is a steel structure member with a length of 6-8m and a width of 20cm. A liquid outlet pipe is embedded in the bottom of the beating tank. Go out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com