Viscous self-emulsifying system as well as preparation method and application thereof

A self-emulsifying, systemic technology, applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve the problems of high resistance to chemical agents, low permeability, and no popularization and application, so as to achieve unobtrusive selectivity, Emulsification speed is fast and the effect of improving oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

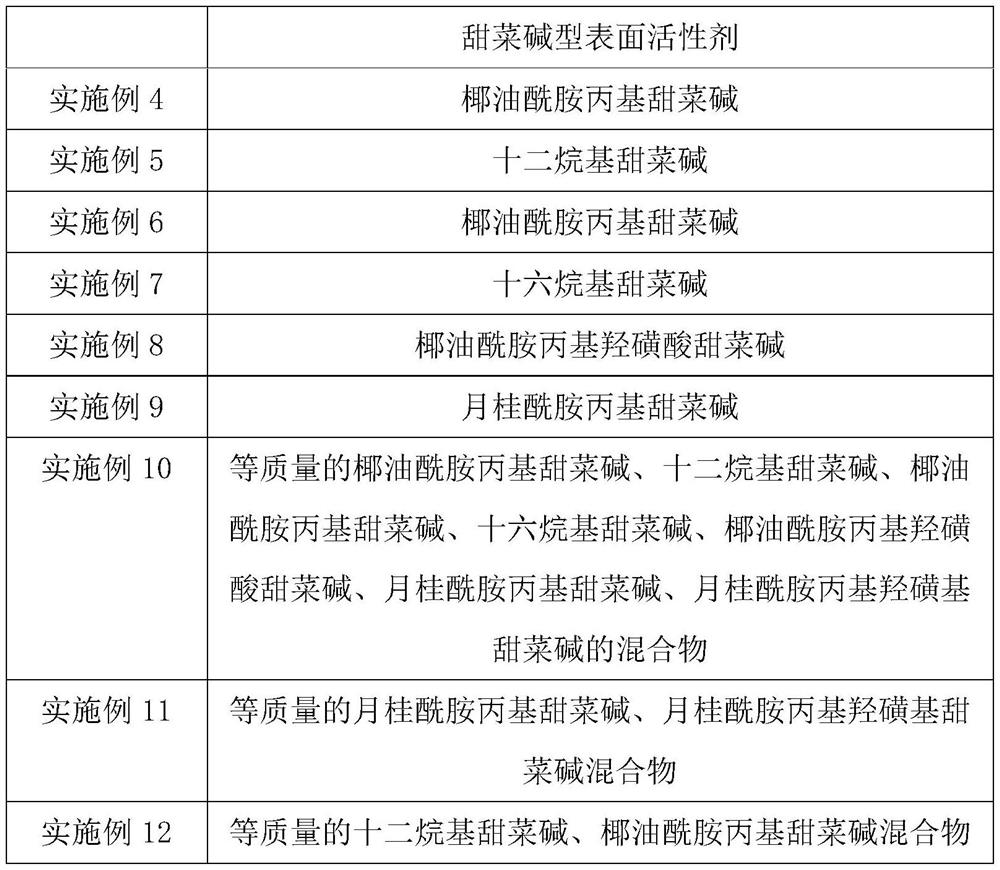

[0051] Viscous self-emulsifying system comprising betaine-type surfactants and builders in which:

[0052] The mass ratio of betaine surfactant and auxiliary agent is 1:0.08;

[0053] The structural formula of the auxiliary agent is as follows:

[0054] n=3.

[0055] Further, the betaine-type surfactant is lauryl amidopropyl hydroxysultaine.

[0056] The preparation method of viscous self-emulsifying system comprises the following steps:

[0057] (1) Get the betaine type surfactant of formula quantity, be warming up to 40 ℃, stir 30 minutes;

[0058] (2) Add the formulated amount of additives to the betaine-type surfactant treated in step (1), stir evenly, and cool down to room temperature to obtain a viscous self-emulsifying system.

[0059] The viscous self-emulsifying system obtained in Example 1 was tested: the aqueous solution of the viscous self-emulsifying system with a concentration of 0.3% had a viscosity of 15mPa.s at 60°C, which was much higher than the viscos...

Embodiment 2

[0085] Viscous self-emulsifying system comprising betaine-type surfactants and builders in which:

[0086] The mass ratio of betaine surfactant and auxiliary agent is 1:0.8;

[0087] The structural formula of the auxiliary agent is as follows:

[0088] n=6.

[0089] Further, the betaine-type surfactant is cocamidopropyl betaine.

[0090] The preparation method of viscous self-emulsifying system comprises the following steps:

[0091] (1) Get the betaine type surfactant of formula quantity, be warming up to 50 ℃, stir 20 minutes;

[0092] (2) Add the formulated amount of additives to the betaine-type surfactant treated in step (1), stir evenly, and cool down to room temperature to obtain a viscous self-emulsifying system.

[0093] Test the viscous self-emulsifying system obtained in Example 2: the viscosity of the aqueous solution of the viscous self-emulsifying system with a concentration of 0.3% is 14.5mPa.s at 60°C, which is much higher than the viscosity reducer for h...

Embodiment 3

[0119] Viscous self-emulsifying system comprising betaine-type surfactants and builders in which:

[0120] The mass ratio of betaine surfactant and auxiliary agent is 1:0:01;

[0121] The structural formula of the auxiliary agent is as follows:

[0122] n=1.

[0123] Further, the betaine-type surfactant is lauryl betaine.

[0124] The preparation method of viscous self-emulsifying system comprises the following steps:

[0125] (1) Get the betaine type surfactant of formula quantity, be warming up to 30 ℃, stir 60 minutes;

[0126] (2) Add the formulated amount of additives to the betaine-type surfactant treated in step (1), stir evenly, and cool down to room temperature to obtain a viscous self-emulsifying system.

[0127] Test the viscous self-emulsifying system obtained in Example 3: the viscosity of the aqueous solution of the viscous self-emulsifying system with a concentration of 0.3% is 15.6mPa.s at 60°C, which is much higher than the viscosity reducer for heavy oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com