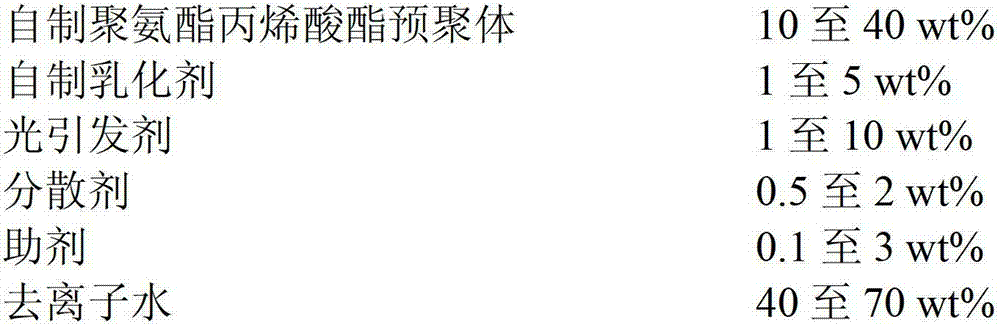

Environment-friendly water-based UV (ultraviolet) curable coating and production method

A light-curing coating, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of organic solvent environmental pollution stability and paint film mechanical properties, achieve great promotion and application value, and increase compatibility , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

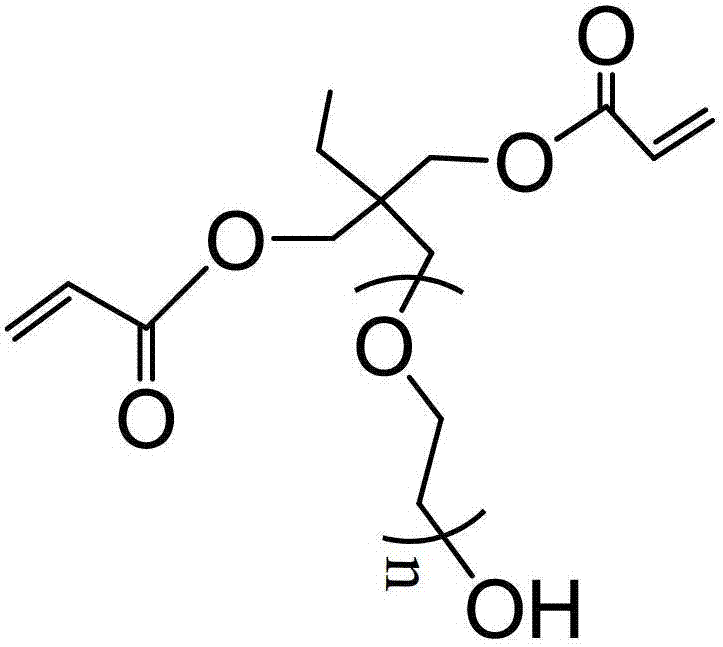

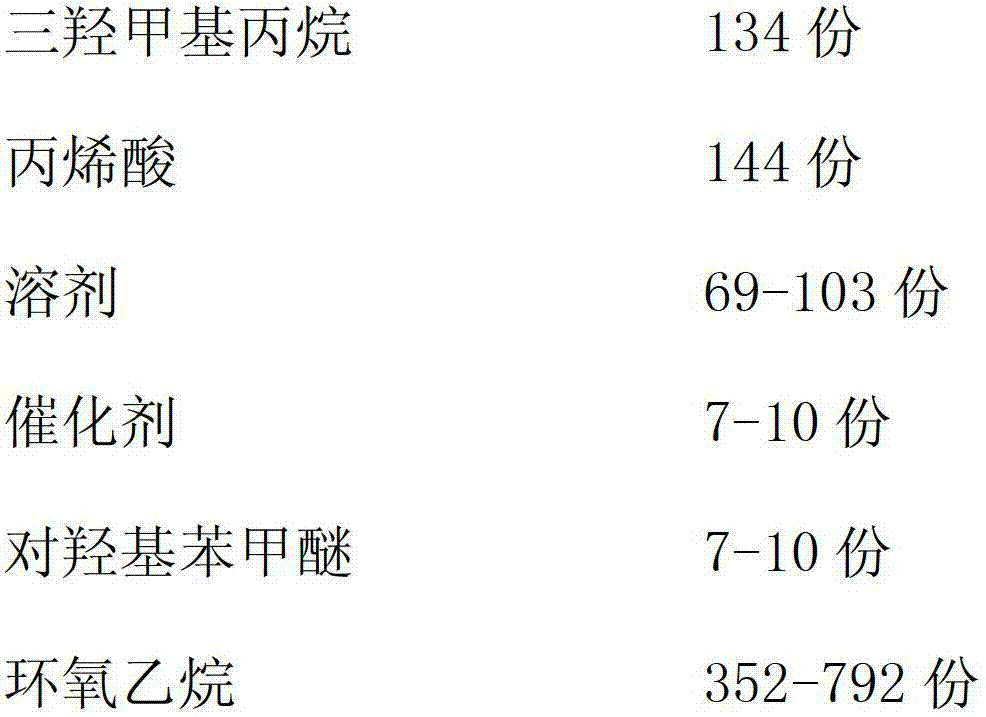

Method used

Image

Examples

Embodiment 1

[0029] The specific implementation steps are as follows:

[0030] (1) Add resin, emulsifier, and part of defoamer (accounting for 20% to 60% of the total amount of defoamer) into the emulsification tank and raise the temperature to 30 to 50°C and mix thoroughly;

[0031] (2) Dispersant, wetting agent, part of defoamer (accounting for 40% to 80% of the total amount of defoamer), and leveling agent are added for mixing;

[0032] (3) The solid photoinitiator and deionized water are mixed in proportion and then added to the above system according to the proportion and mixed evenly;

[0033] (4) Pass through a 600-mesh filter to obtain a milky white water-based environmentally friendly UV light-curing coating.

example 1

[0037] Example 1, comparative example one emulsification time and the performance comparison of the prepared emulsion

[0038]

[0039] Through comparison, it is found that the solvent resistance of the coating of the present invention reaches the level of imported products, and the emulsification speed is faster, the stability of the emulsion is better at 3500 revolutions on a refrigerated centrifuge, and the hardness of the prepared paint film is higher.

[0040] The water-based UV photocurable coating of the present invention can be constructed by means of roller coating, curtain coating and spray coating. The prepared coating has better adhesion on PVC / ABS / vacuum electroplating / ash wood board than grade two, can withstand 10 times of cold and heat cycles of minus 40 degrees and 40 degrees without cracking, and the hardness can be adjusted from H to 3H .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com