Antigen emulsification equipment and emulsification method

An emulsification equipment and antigen technology, applied in chemical instruments and methods, mixing methods, dissolution, etc., can solve the problems of large loss of antigen, incomplete emulsification, destruction of antigen, etc., to achieve fast emulsification speed, large loss of solution, and avoid immunogenicity Sexually destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

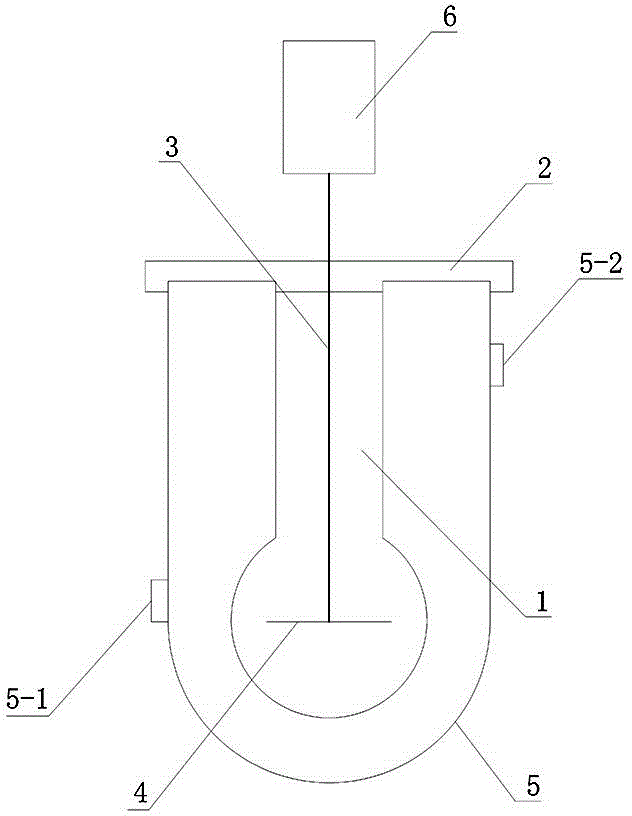

[0022] Embodiment: the antigen emulsification equipment of the present embodiment is as figure 1 As shown, it includes an emulsifying container 1, an upper cover 2, a stirring rod 3, a knife head 4 and a jacket 5, wherein the emulsifying container 1 is made of glass, has a slender neck and a spherical bottom, and is installed at the bottom of the stirring rod 3 The cutter head 4 at the end is S-shaped, the stirring rod 3 extends into the emulsification container 1 and the cutter head 4 is located at the spherical center of the bottom of the emulsification container 1 . A jacket 5 made of plastic is placed outside the emulsification container 1 , and a gap for passing cooling water is formed between the two. A cooling water inlet 5-1 is opened on the lower part of the jacket 5, and a cooling water outlet 5-2 is opened on the upper part, the top of the jacket 5 and the emulsification container 1 are sealed with the upper cover 2, and the top of the stirring rod 3 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com