Gold-imitation coated glass and preparation technology thereof

A technology of coating glass and preparation process, applied in glass/slag layered products, metal layered products, layered products, etc., can solve the problems of poor appearance, low gloss, poor film roughness, etc. Color selection effect, strong imitation gold decoration, film layer and anti-acid corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

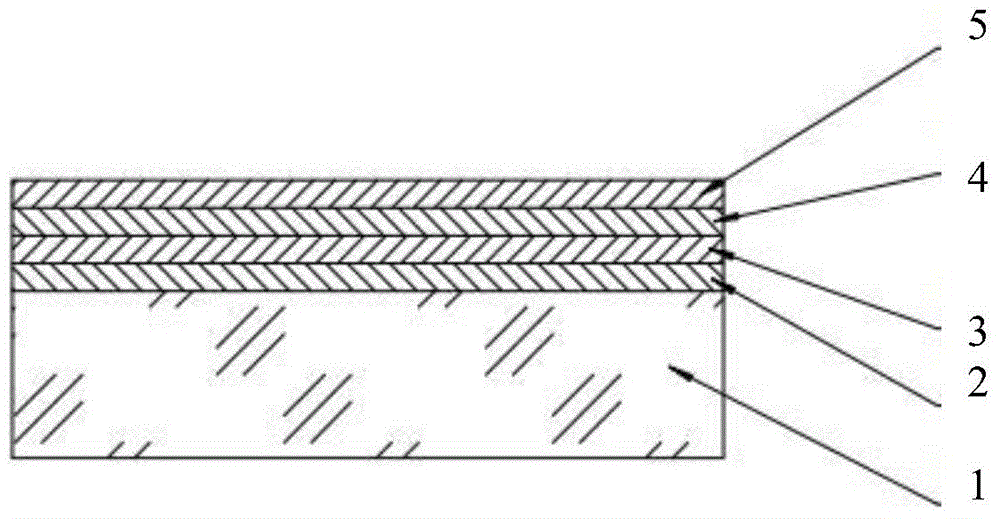

[0032] Such as figure 1 As shown, a kind of imitation gold coated glass of the present invention comprises a glass substrate 1, and a hydrophilic ionization layer 2, a pure titanium film layer 3, pure titanium and titanium nitride placed on the surface of the glass substrate 1 in sequence The mixed film layer 4 and the nitrogen-enriched heat treatment layer 5. The hydrophilic ionization layer 2 is an oxygen ion bombardment treatment layer with a thickness ranging from 0.01 to 0.1 microns. The thickness range of the pure titanium film layer 3 is 0.02-0.1 microns. The thickness range of the mixed film layer 4 of pure titanium and titanium nitride is 0.05-0.2 microns. The thickness range of the nitrogen-enriched heat treatment layer 5 is 0.02-0.1 microns.

[0033] The invention also discloses a preparation process of imitation gold coated glass, the specific steps of which are:

[0034] (1) Dry the glass substrate 1 after ultrasonic cleaning, put it into a vacuum chamber to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com