Coloring liquid and coloring method for chemically coloring stainless steel surface into black

A technology of surface chemistry and coloring solution, applied in the direction of surface reaction electrolytic coating, metal material coating process, electrolytic coating, etc., can solve the problem of black tending to turn bluish color reproducibility, and achieve wear resistance and corrosion resistance Improvement, simple coloring process, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

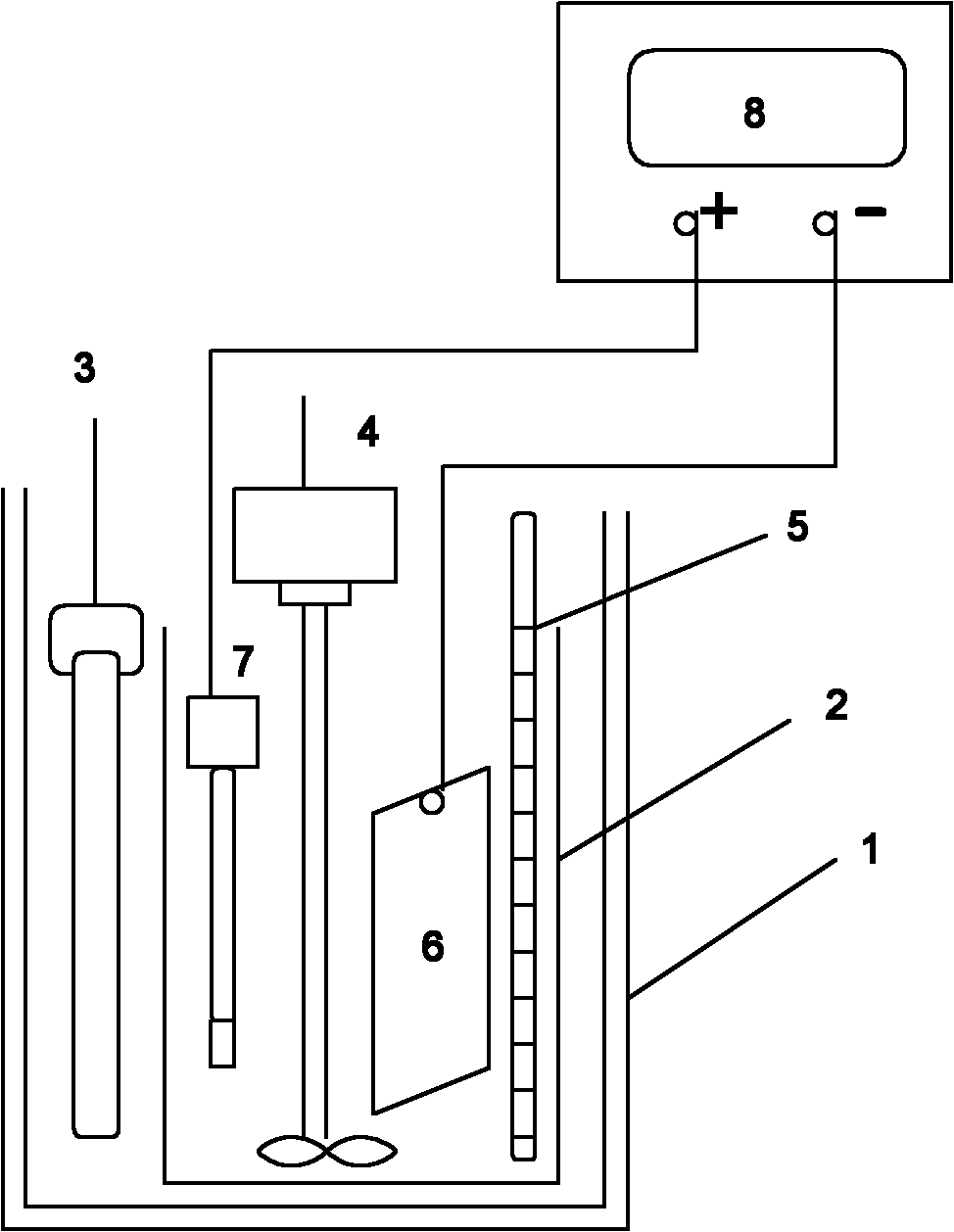

Method used

Image

Examples

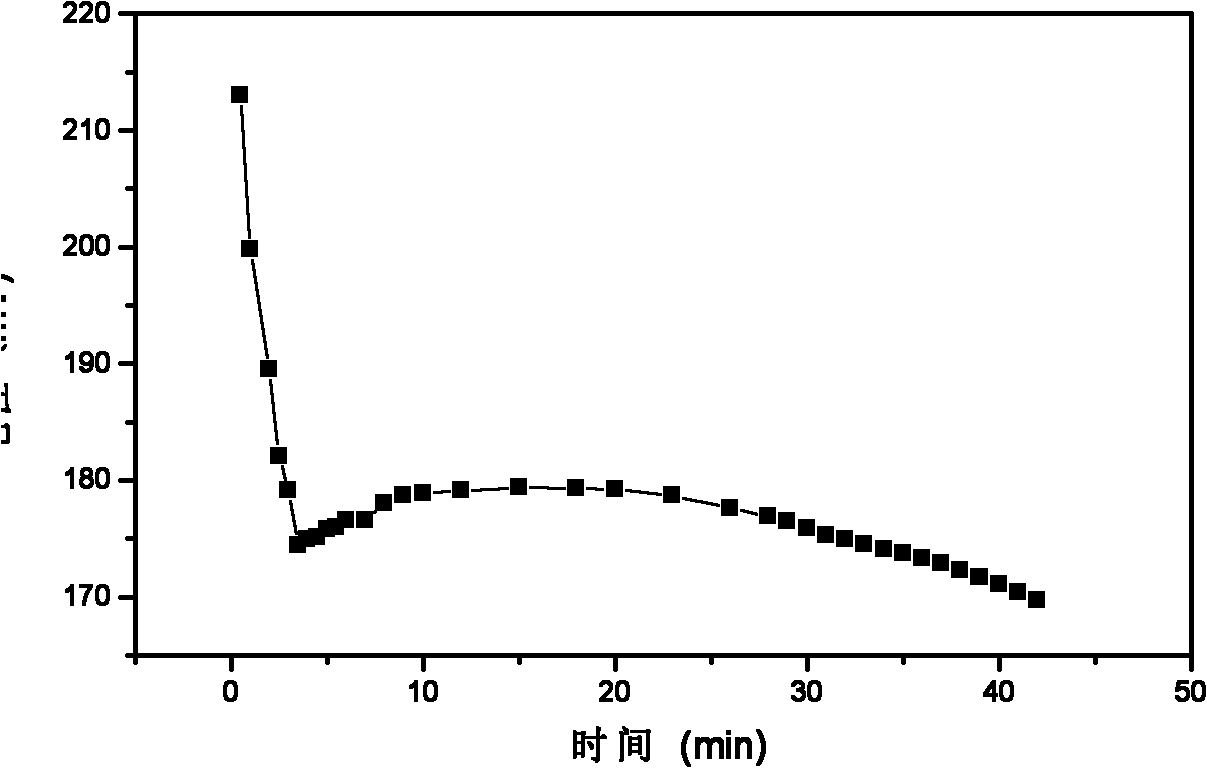

Embodiment 1

[0023] The 304 stainless steel plate (specification: 400mm×300mm×0.7mm) produced by Taiyuan Iron and Steel Works is mechanically mirror polished (8K grinding), placed in an electrolyte at 40°C, and the current density dA=0.25A / dm is adjusted 2 , electrolysis for 3min. After the electrolysis is completed, it is then placed in a coloring solution at 90°C for coloring. Among them, the coloring solution is composed of: 220g / L chromic anhydride, 250mL / L 98% concentrated sulfuric acid, 160g / L chromium sulfate, 6g / L iron sulfate, 2.5g / L manganese sulfate, 1.5g / L cerium sulfate, and the rest for water. Use a potentiometer to monitor the potential value of the coloring process. When the potential difference reaches 10.1mV, take the stainless steel out of the coloring solution, clean it with tap water, and then put the stainless steel into a 3% sodium silicate solution for sealing. The temperature is 90°C, and the treatment time is 15 minutes. After the hole sealing is completed, dry...

Embodiment 2

[0026]The 304 stainless steel plate (specification: 400mm×300mm×0.55mm) produced by Guangzhou Lianzhong Stainless Steel Co., Ltd. is mechanically mirror polished, placed in the electrolyte at 38°C, and the current density dA=0.18A / dm is adjusted 2 , electrolysis for 3.5min. After the electrolysis is completed, it is washed with tap water, and then placed in a coloring solution at 91° C. for coloring. Among them, the coloring solution is composed of: 200g / L chromic anhydride, 220mL / L 98% concentrated sulfuric acid, 120g / L chromium sulfate, 5g / L iron sulfate, 2g / L manganese sulfate, 1g / L cerium sulfate, and the rest is water . During the coloring process, a potentiometer is used to monitor the potential value. When the potential difference reaches 10.3mV, the stainless steel is taken out of the coloring solution, cleaned with tap water, and then put into a 3% sodium silicate solution for sealing. The temperature is 80°C, and the treatment time is 22 minutes. After the hole se...

Embodiment 3

[0029] The 304 stainless steel tube (specification: Φ30mm×150mm×1.0mm) produced by Guangzhou Lianzhong Stainless Steel Co., Ltd. is mechanically mirror-polished, placed in the electrolyte at 35°C, and the current density dA=0.1A / dm is adjusted. 2 , electrolysis for 3min. After the electrolysis is completed, the residual electrolyte solution on the surface of the inner and outer stainless steel tubes is cleaned with tap water, and then placed in a coloring solution at 92°C for coloring. Among them, the coloring solution is composed of: 250g / L chromic anhydride, 280mL / L 98% concentrated sulfuric acid, 170g / L chromium sulfate, 5g / L iron sulfate, 3g / L manganese sulfate, 1.5g / L cerium sulfate, and the rest are water. Use a potentiometer to monitor the potential value during the coloring process. When the potential difference reaches 12.5mV, take the stainless steel tube out of the coloring solution, clean the residual coloring solution, dry it with 90°C hot air, and seal it with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com