Method for coloring alginate fibers by nano pigment

A nano-pigment and seaweed fiber technology, which is applied in the fields of fine chemical industry and material science, achieves the effect of high utilization rate of pigment, simple coloring process and overcoming damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

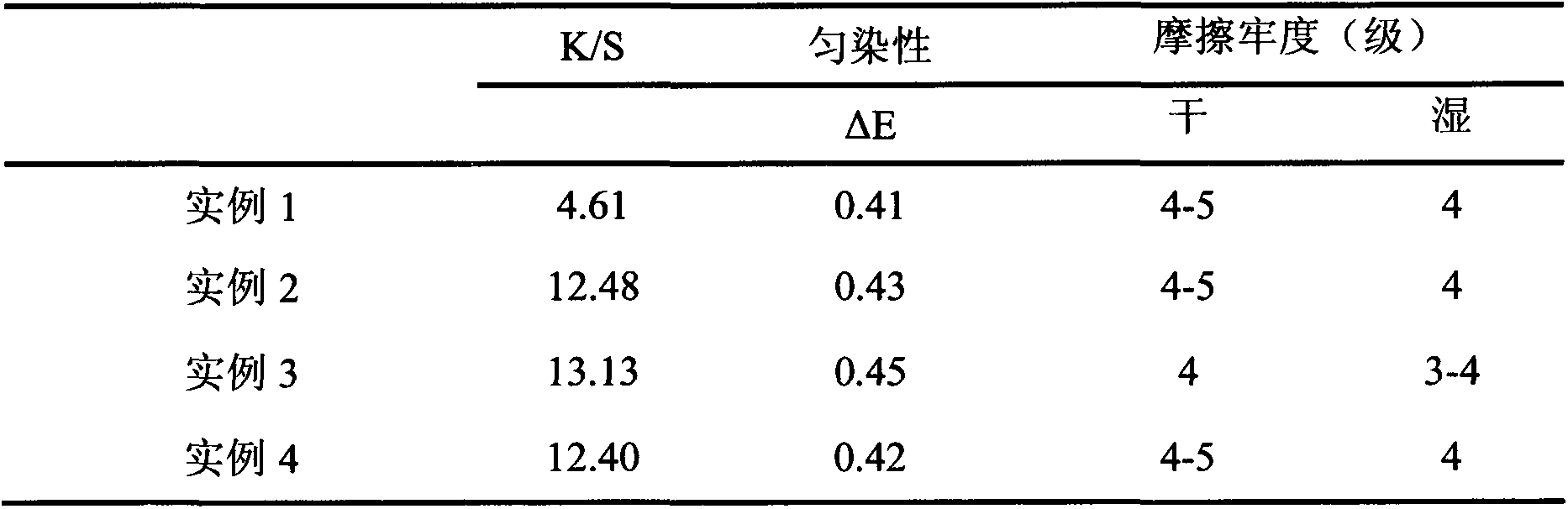

Examples

example 1

[0013] Get 1g styrene-maleic anhydride copolymer (number average molecular weight 4000) and 0.1g sodium dodecylbenzene sulfonate and dissolve in 88.9g deionized water, use a pH regulator to adjust the pH of the system to be 7-8, then add 10gC .I. Pigment Red 122, after high-speed dispersion treatment for 0.5h, transferred to a sand mill for dispersing for 8h to obtain a nano C.I. Pigment Red 122 dispersion with a particle size of 153nm and a pigment mass fraction of 10%. Take 4g of sodium alginate and dissolve it in 95.96g of deionized water, stir to make it fully dissolved, take 0.04g of nano C.I. pigment red 122 dispersion and add it to the sodium alginate solution, stir and disperse evenly, filter and vacuum defoam for 10h, The nano pigment seaweed fiber spinning solution is obtained. Adjust the temperature of the nano fluorescent pigment seaweed fiber spinning solution to 45°C, and squeeze the spinning solution through the spinneret hole to a CaCl with a temperature of 25°...

example 2

[0015] Dissolve 10g of sodium carboxymethylcellulose (number average molecular weight 2000) and 2g of Tween80 in 68g of deionized water, use a pH regulator to adjust the pH of the system to 7-8, then add 20g of C.I. Pigment Blue 15:3, and disperse at high speed After treatment for 0.5h, it was transferred to a sand mill for dispersing for 4h to obtain a nano C.I. pigment blue 15:3 dispersion with a particle size of 153nm and a pigment mass fraction of 20%. Take 10g of sodium alginate and dissolve it in 85g of deionized water, stir to make it fully dissolved, take 5g of nano C.I. pigment blue 15:3 dispersion and add it to the sodium alginate solution, stir and disperse evenly, filter and vacuum defoam for 10h, The nano pigment seaweed fiber spinning solution is obtained. Adjust the temperature of the nano-pigment seaweed fiber spinning solution to 60°C, and squeeze the spinning solution through the spinneret hole to a CaCl with a temperature of 60°C and a solubility of 5%. 2 i...

example 3

[0017] Take 5g of sodium alginate (number average molecular weight 3500) and 1g of Pingpingjiao dissolved in 54g of deionized water, use a pH regulator to adjust the pH of the system to 7-8, then add 40g of carbon black, transfer after 0.5h of high-speed dispersion treatment Disperse in a sand mill for 8 hours to obtain a nano-carbon black dispersion with a particle size of 153 nm and a pigment mass fraction of 40%. Take 6g of sodium alginate and dissolve it in 85g of deionized water, stir to make it fully dissolved, take 0.65g of nano-carbon black dispersion and add it to the sodium alginate solution, stir and disperse evenly, filter and vacuum defoam for 10 hours to obtain nano-pigments Seaweed fiber spinning solution. Adjust the temperature of the nano-pigment seaweed fiber spinning solution to 55°C, and squeeze the spinning solution through the spinneret hole to a CaCl with a temperature of 40°C and a solubility of 6%. 2 in a coagulation bath, then washed with water, stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com