Three-way connecting fitting of face pipe

A technology for connecting fittings and face tubes, applied in the direction of connecting components, rod connections, mechanical equipment, etc., can solve problems such as the inability to form a good seal on the face tube ports, increase the process cycle and difficulty, and the lack of toughness of aluminum alloy fittings, so as to achieve waterproof Good effect, easy to promote and apply, and the effect of enhanced security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

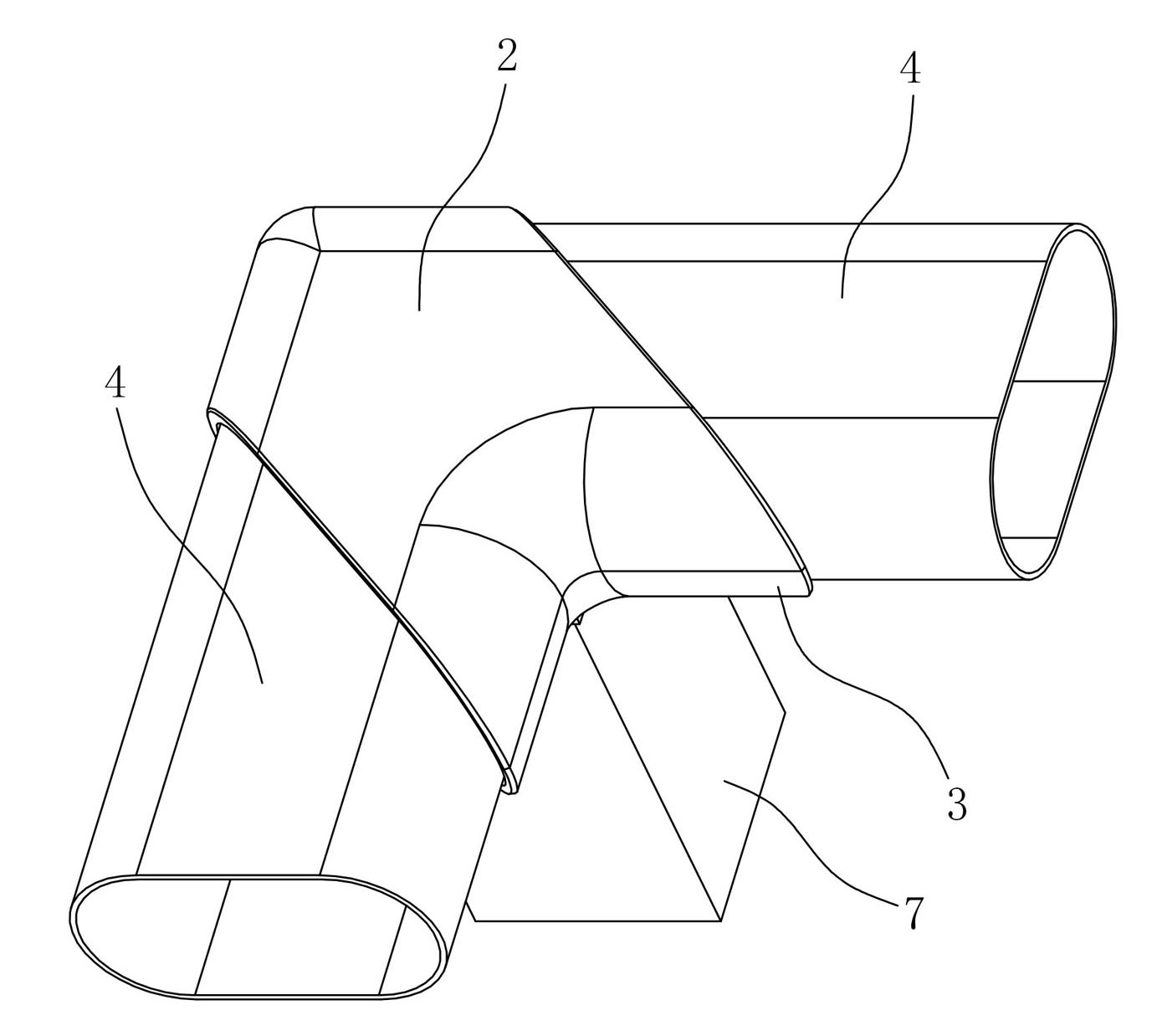

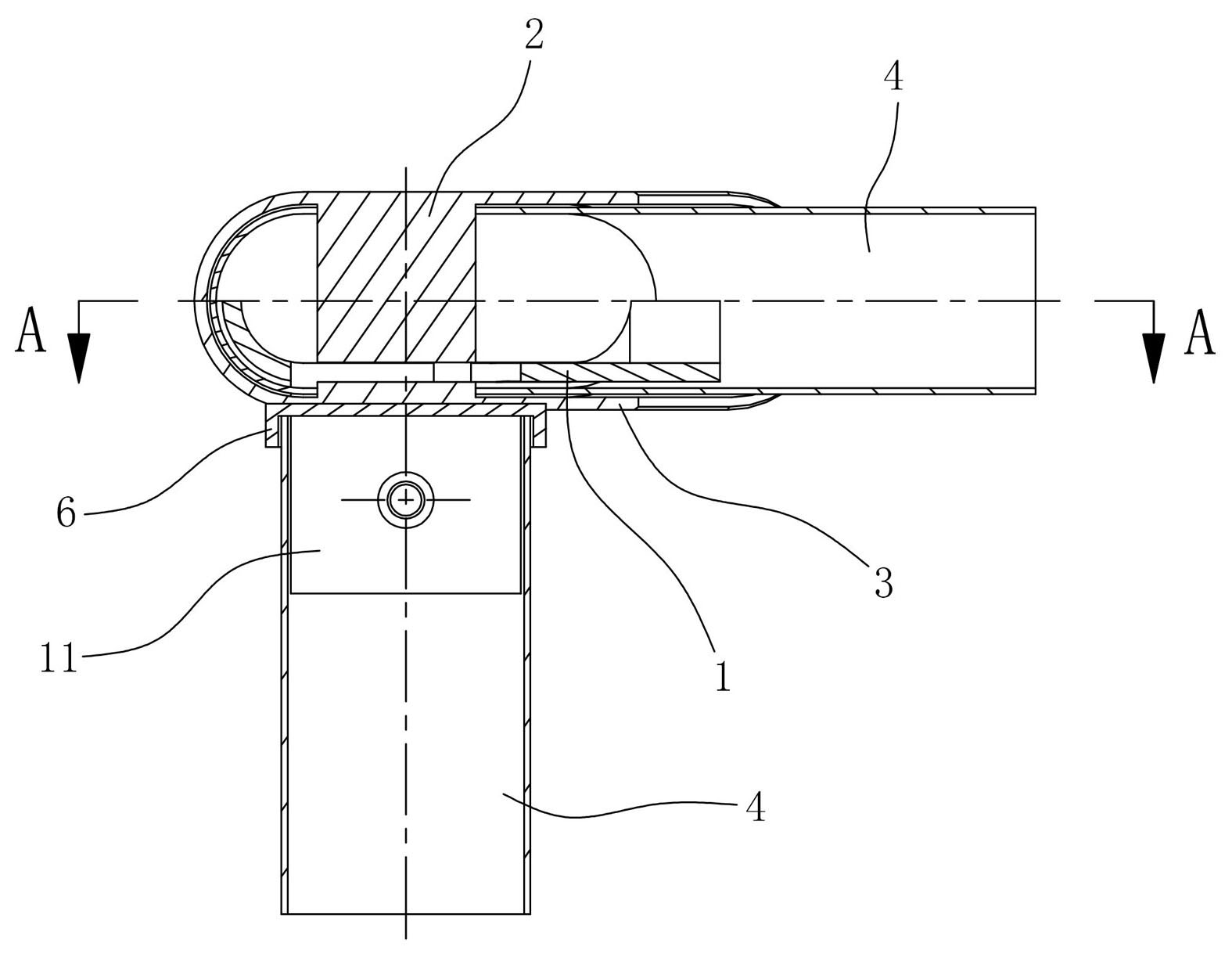

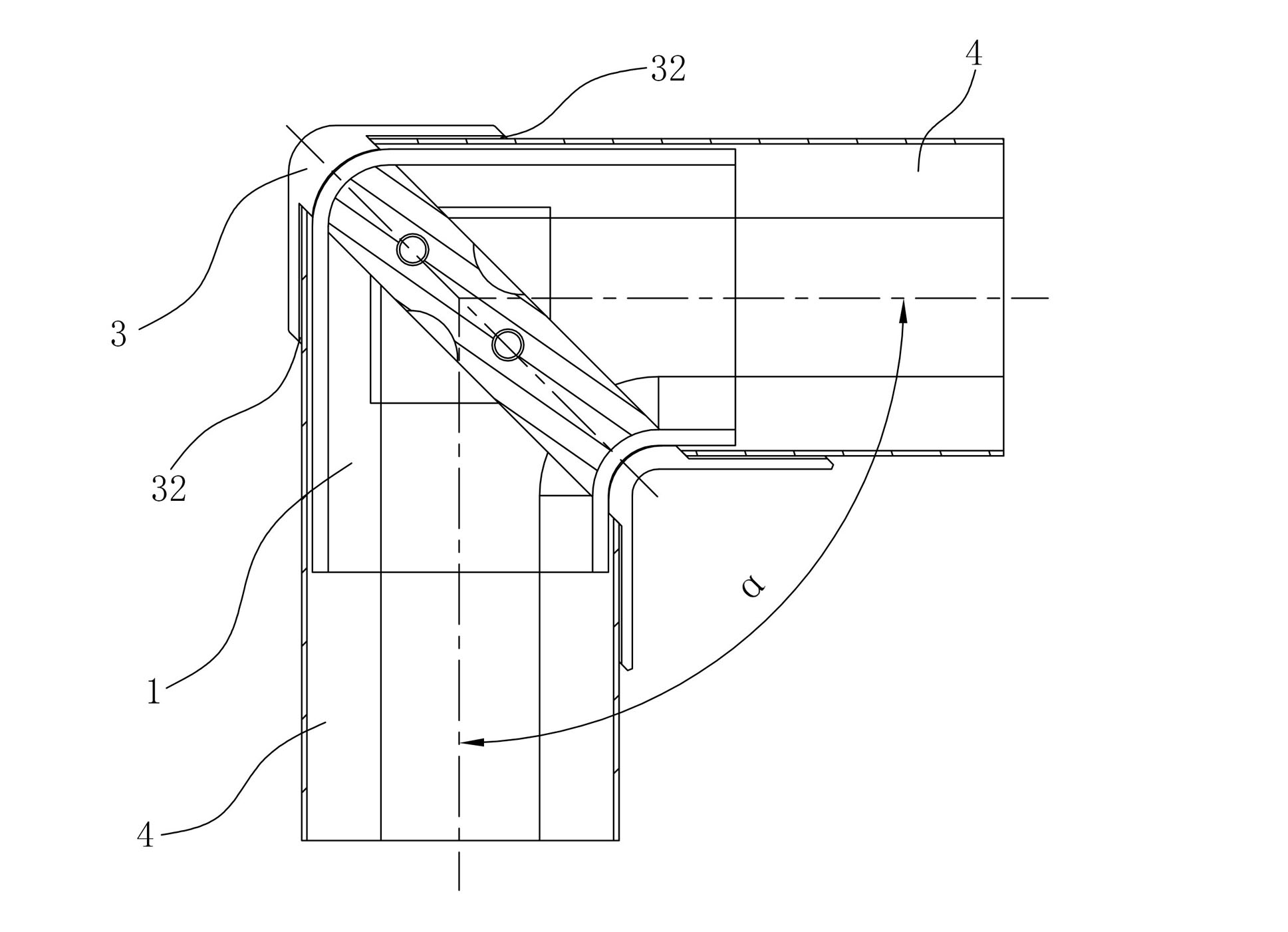

[0025] Figure 1 to Figure 7 It shows an embodiment of a surface pipe tee connection fitting of the present invention, the connection fitting includes a rigid plate 1, an upper plastic material ferrule 2 and a lower plastic material ferrule 3, and the upper plastic material ferrule 2 and the lower plastic material ferrule The sleeves 3 are interlocked and connected by tenons to form a seal for the surface pipe 4. The rigid plate 1 is placed in the upper plastic material ferrule 2 and the lower plastic material ferrule 3 that are interlocked to form a seal for connecting the surface pipe 4. As for the connector, the rigid plate 1 is provided with a column connecting portion 11 passing through the lower plastic material ferrule 3 . Compared with the existing aluminum alloy fittings, the present invention connects the surface pipe 4 and the column 7 through the rigid plate 1, the connection strength is greatly improved, it is not easy to be damaged or broken, and the safety is en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com