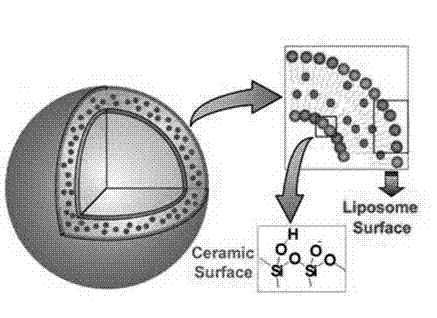

Silicon plastid microcapsule and preparation method thereof

A technology of microcapsules and siliceous bodies, applied in the field of biomedical materials, can solve the problems of uniform particle size, wide distribution range of siliceous body particle sizes, and affecting practical applications, and achieve good stability, uniform and controllable particle size, Solve the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

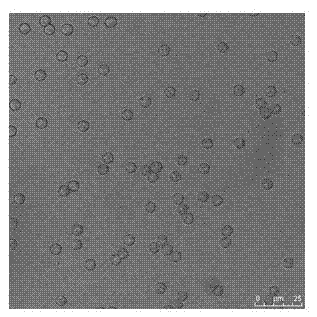

[0034] (1) Prepare 0.025M Na respectively 2 CO 3 、 Ca(NO 3 ) 2 100mL each solution Ca(NO 3 ) 2 Add 400 mg polystyrene sulfonate sodium (PSS) to the solution, and after it is completely dissolved, quickly add Na 2 CO 3 Solution, stirred at 600 rpm for 15s, left to stand for 20min, centrifuged and washed three times to obtain calcium carbonate particles with a particle size of 5 microns, the laser confocal photo is shown in figure 2 .

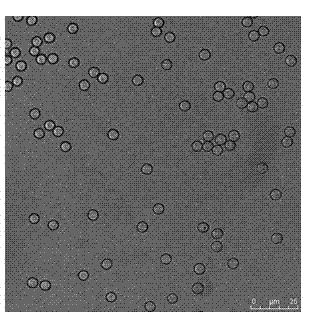

[0035] (2) In negatively charged CaCO 3 The surface is coated with polyallylamine hydrochloride (PAH) through the principle of electrostatic layer-by-layer self-assembly to obtain CaCO 3 -PAH makes the surface positively charged and enhances the ability to combine with organic-inorganic lipids. Laser confocal photos are shown in image 3 .

[0036] (3) Precisely weigh 10 mg of organic-inorganic lipid 1, dissolve it in 2 mL of chloroform, remove the chloroform by rotary evaporation, and form a transparent lipid film at the bo...

Embodiment 2

[0038] (1) Same as Step 1 of Example 1;

[0039] (2) Same as step 2 of embodiment 1;

[0040] (3) Same as Step 3 of Example 1, except that the lipid used is organic-inorganic lipid 2 dissolved in 2 mL of dichloromethane.

Embodiment 3

[0042] (1) With step 1 of embodiment 1, the difference is that the stirring rate is 700 rpm, the time is 15s, and the diameter of the calcium carbonate particles prepared is about 3 ~ 4 microns;

[0043] (2) Same as step 2 of embodiment 1;

[0044] (3) Same as Step 3 of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com