Method for producing variable color wire rod

A production method and wire technology, which is applied in the field of color-changing wire production, can solve the problems of lack of beautiful individual color and single color, and achieve the effect of adding individual characteristics and filling color defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

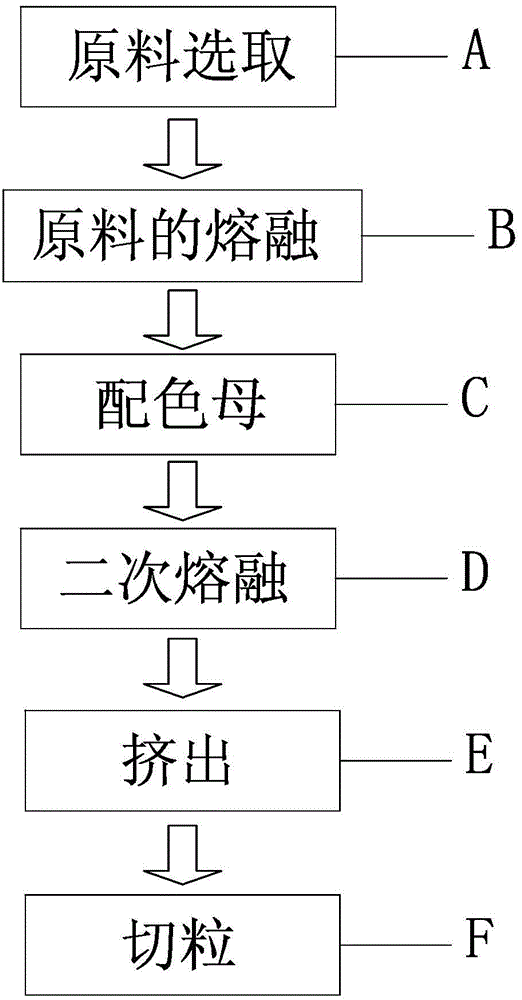

[0017] refer to figure 1 As shown, it is the first specific embodiment of the manufacturing method of a color-changing wire disclosed in the present invention. In this embodiment, the manufacturing method of the color-changing wire includes the following steps:

[0018] A. Raw material selection: select thermoplastic elastomer TPE as raw material;

[0019] B. Melting of raw materials: Put the selected thermoplastic elastomer TPE into the equipment and melt at 160 °C;

[0020] C. Color masterbatch: add color masterbatch with a weight ratio of 0.1% to the raw material melted in step B;

[0021] D. Secondary melting: Put the thermoplastic elastomer TPE of the color masterbatch into the equipment again, perform secondary melting at 160°C, and stir during the melting process;

[0022] E. Extrusion: extrude the stirred material, and the extruded material is in the shape of a wire;

[0023] F. Pelletizing: cutting the extruded wire-like material into pellets to obtain a color-chan...

Embodiment 2

[0025] combine figure 1 As shown, it is the second specific embodiment of a manufacturing method of a color-changing wire disclosed in the present invention. In this embodiment, the manufacturing method includes the following steps:

[0026] A. Raw material selection: select thermoplastic elastomer TPE as raw material;

[0027] B. Melting of raw materials: Put the selected thermoplastic elastomer TPE into the equipment and melt at 200 °C;

[0028] C. Color masterbatch: add color masterbatch with a weight ratio of 0.5% to the raw material melted in step B;

[0029] D. Secondary melting: Put the thermoplastic elastomer TPE of the color masterbatch into the equipment again, perform secondary melting at 200 ° C, and stir during the melting process;

[0030] E. Extrusion: extrude the stirred material, and the extruded material is in the shape of a wire;

[0031] F. Pelletizing: cutting the extruded wire-like material into pellets to obtain a color-changing wire.

Embodiment 3

[0033] continue to combine figure 1 As shown, it is the third specific embodiment of a manufacturing method of a color-changing wire disclosed in the present invention. In this embodiment, the manufacturing method includes the following steps:

[0034] A. Raw material selection: select thermoplastic elastomer TPE as raw material;

[0035] B. Melting of raw materials: Put the selected thermoplastic elastomer TPE into the equipment and melt at 240°C;

[0036] C. Color masterbatch: add color masterbatch with a weight ratio of 1% to the raw material melted in step B;

[0037] D. Secondary melting: Put the thermoplastic elastomer TPE of the color masterbatch into the equipment again, perform secondary melting at 240 ° C, and stir during the melting process;

[0038] E. Extrusion: extrude the stirred material, and the extruded material is in the shape of a wire;

[0039] F. Pelletizing: cutting the extruded wire-like material into pellets to obtain a color-changing wire.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com