Simulated rubber transfer film and preparation method thereof

A transfer film and rubber technology, which is applied to clothing, printing devices, ink transfer from original manuscripts, etc., can solve the problem that single-color rubber-type chemical protective clothing cannot meet the requirements of military camouflage, the printed pattern has a single color, and it is difficult to print in color and other issues, to achieve the effect of easy industrialization, popularization, bright colors and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

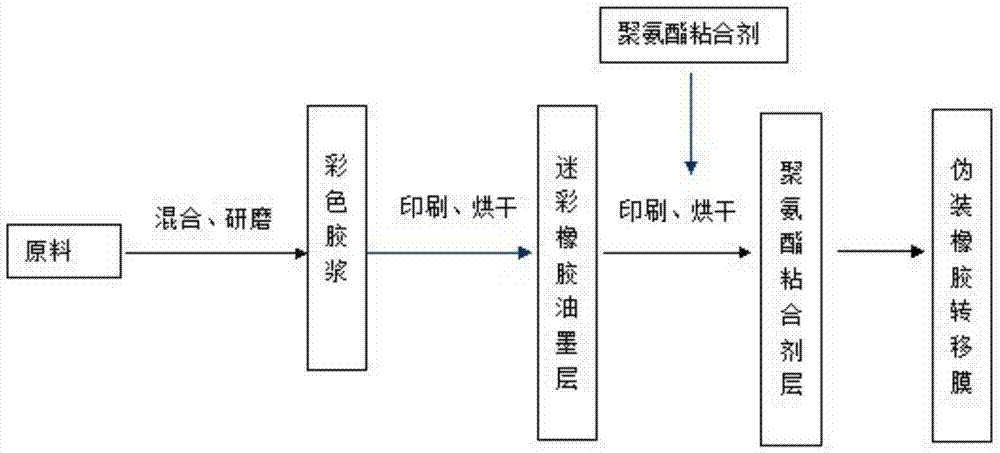

[0030] The specific preparation process of the preparation method of the above-mentioned camouflaged rubber transfer film of the present invention (see figure 2 )yes:

[0031] a. Prepare the color glue according to the color configuration requirements of the camouflage pattern: fully mix and stir the above raw materials, and perform ultrafine grinding to make the corresponding color glue;

[0032] b, printing the camouflage rubber ink layer: the color glue prepared in step a is printed on the biaxially oriented polypropylene film layer 1 by a gravure printing machine, wherein the sizing amount of the color glue is 10-15g / m 2 , the printing speed is 20-30m / min; after printing, dry at a temperature of 50-70°C for 10-15s, that is, a camouflage rubber ink layer 2 is formed on the upper surface of the biaxially oriented polypropylene film layer 1;

[0033] C, print polyurethane adhesive layer: the upper surface of the camouflage rubber ink layer 2 that makes in step b prints poly...

Embodiment 1

[0041] In this example, a four-color big-leaf woodland camouflage rubber film was prepared.

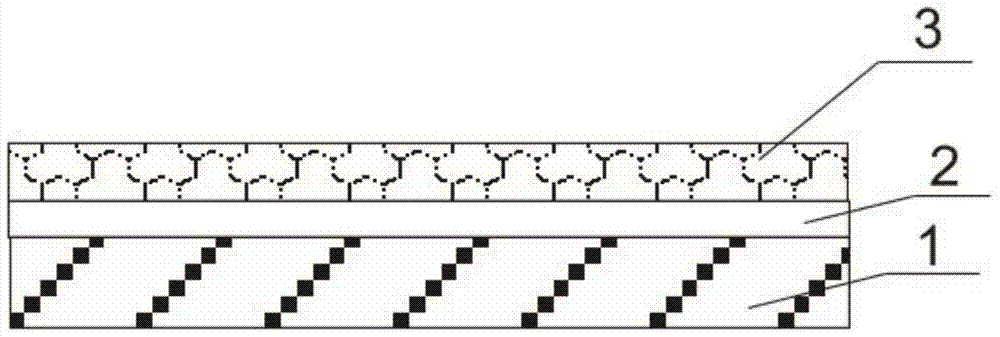

[0042] The design film includes a polyurethane adhesive layer 3, a camouflage rubber ink layer 2 and a biaxially stretched polypropylene film layer 1; the camouflage rubber ink layer 2 is printed on the biaxially stretched polypropylene film layer 1 by a gravure printing machine, and the camouflage rubber The raw materials of the ink layer 2 include pigment, neoprene latex, anti-aging agent, ultraviolet absorber and titanium dioxide; the polyurethane adhesive layer 3 is printed on the camouflage rubber ink layer 2 by a gravure printing machine. Wherein, antioxidant is di-tert-butyl p-cresol, and ultraviolet absorber is UV-531; The total solid content of chloroprene latex is 55%, and particle diameter is 50~55nm (the total solid content of normal chloroprene latex is 30% -60%, the particle size is 50-190nm). The printing plate of the gravure printing machine chooses the woodland camou...

Embodiment 2

[0054] In this example, a four-color large-leaf desert camouflage rubber film was prepared.

[0055] The anti-aging agent in the raw material of the camouflage rubber ink layer 2 in the film of this embodiment is anti-aging agent 4010NA, and the ultraviolet absorber is UV-326; the total solid content of neoprene latex is 50%, and the particle size is 55-60nm. The printing plate of the gravure printing machine chooses the desert camouflage pattern, that is, the four-color big-leaf desert pattern, and the pigment configuration is sandy soil, medium green, dark brown and black.

[0056] The parts by weight of each component in the raw material of the camouflage rubber ink layer 2 consist of:

[0057] Pigment: 10 parts

[0058] Neoprene latex: 100 parts

[0059] Anti-aging agent: 1 part

[0060] UV absorber: 1 part

[0061] Titanium dioxide: 10 parts.

[0062] The specific preparation process of the present embodiment camouflage rubber transfer film is:

[0063] a. Firstly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com