Supercritical fluid spray-dyeing device

A supercritical fluid and fluid technology, applied in dyeing, spray/jet textile material treatment, liquid/gas/steam textile material treatment, etc., can solve the problem of increasing device structure complexity and investment cost, high sealing requirements, Problems such as restricting popularization and application can be achieved to achieve the effects of good level dyeing and continuity, convenient and safe operation, and reasonable and advanced technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

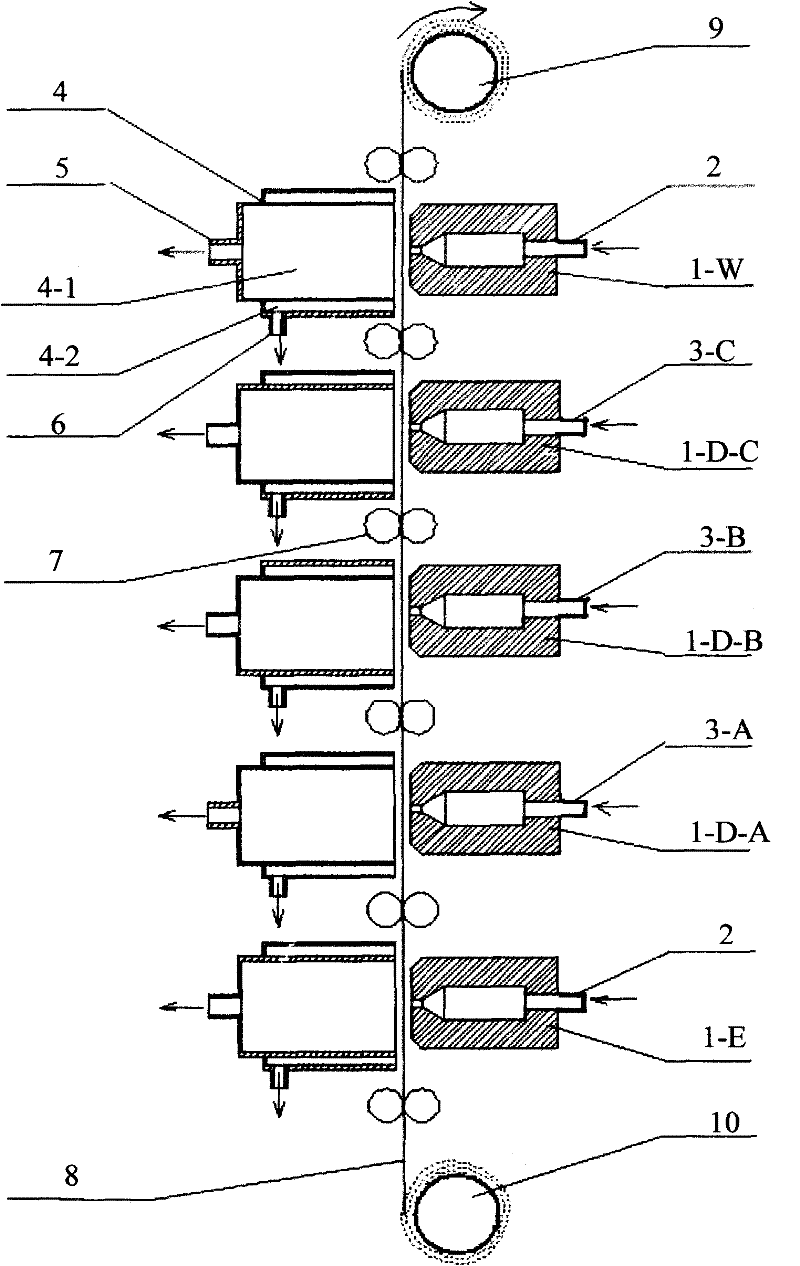

[0023] Embodiment one, such as figure 1 Shown:

[0024] The two ends of the dyed object 8 are wound and tensioned by the active winding roller 9 and the driven winding roller 10, and the dyed object 8 is driven to run. Along the same side of the dyeing process, the extraction nozzle group 1-E, the dye A Dyeing nozzle group 1-D-A, dyeing nozzle group B dyeing nozzle group 1-D-B, dyeing nozzle group C dyeing nozzle group 1-D-C and cleaning nozzle group 1-W, install used fluid recovery device 4 at the corresponding position of each nozzle group, constitute supercritical The single-side spraying process of fluid to the object 8 to be dyed. The supercritical pure fluid pipe 2 connects the extraction nozzle group 1-E and the cleaning nozzle group 1-W with the pure supercritical fluid source; the dye-containing A supercritical fluid pipe 3-A, the dye-containing B supercritical fluid pipe 3-B and the supercritical fluid pipe 3-C containing dye A dyeing nozzle group 1-D-A, dye B dyei...

Embodiment 2

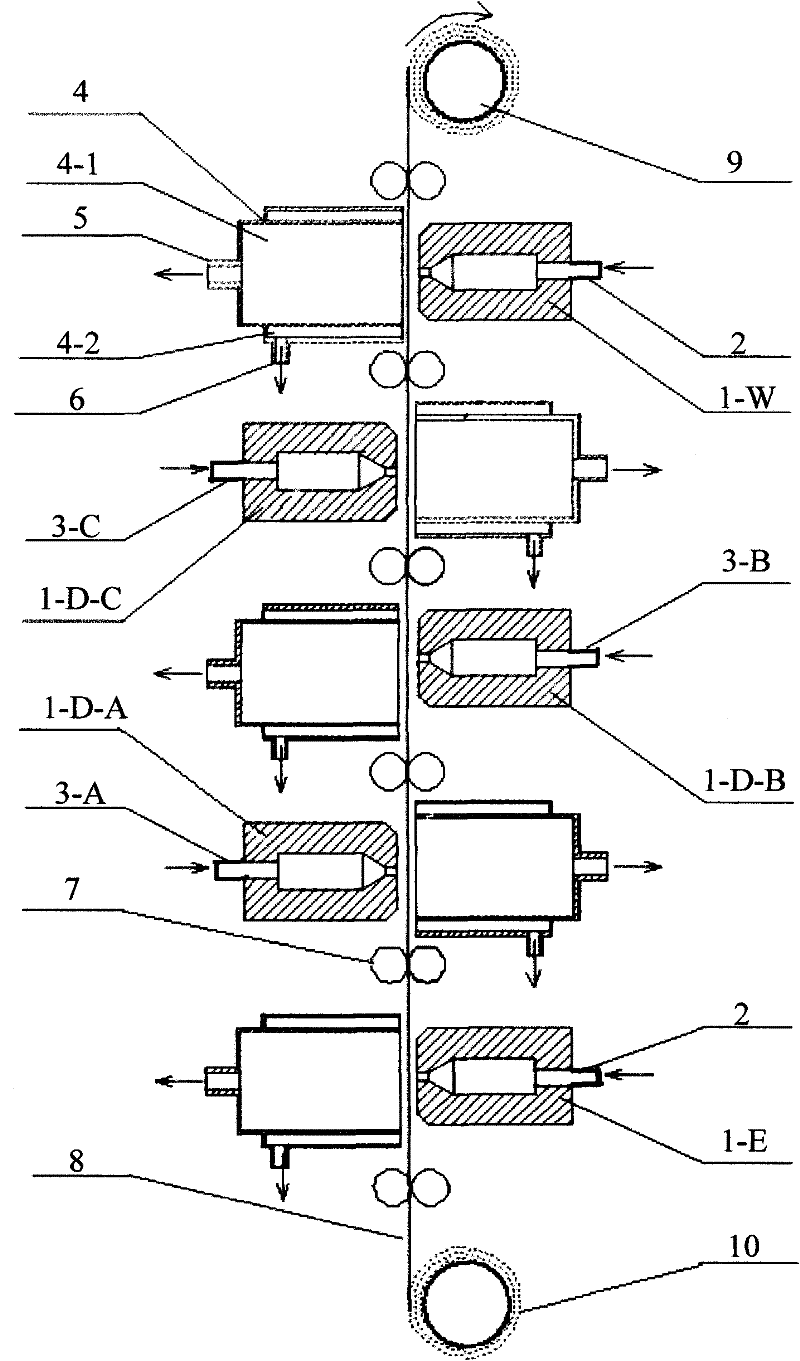

[0034] Embodiment two, such as figure 2 Shown:

[0035] The spraying principle and device flow are the same as those in Embodiment 1, the difference is that the corresponding directions of each nozzle group 1-E~1-W of the device and the respective corresponding used fluid recoverers 4 are alternately installed in the The two sides of the running track of the dyeing process can realize the double-sided spraying and dyeing process of the supercritical fluid on the dyed object 8 .

Embodiment 3

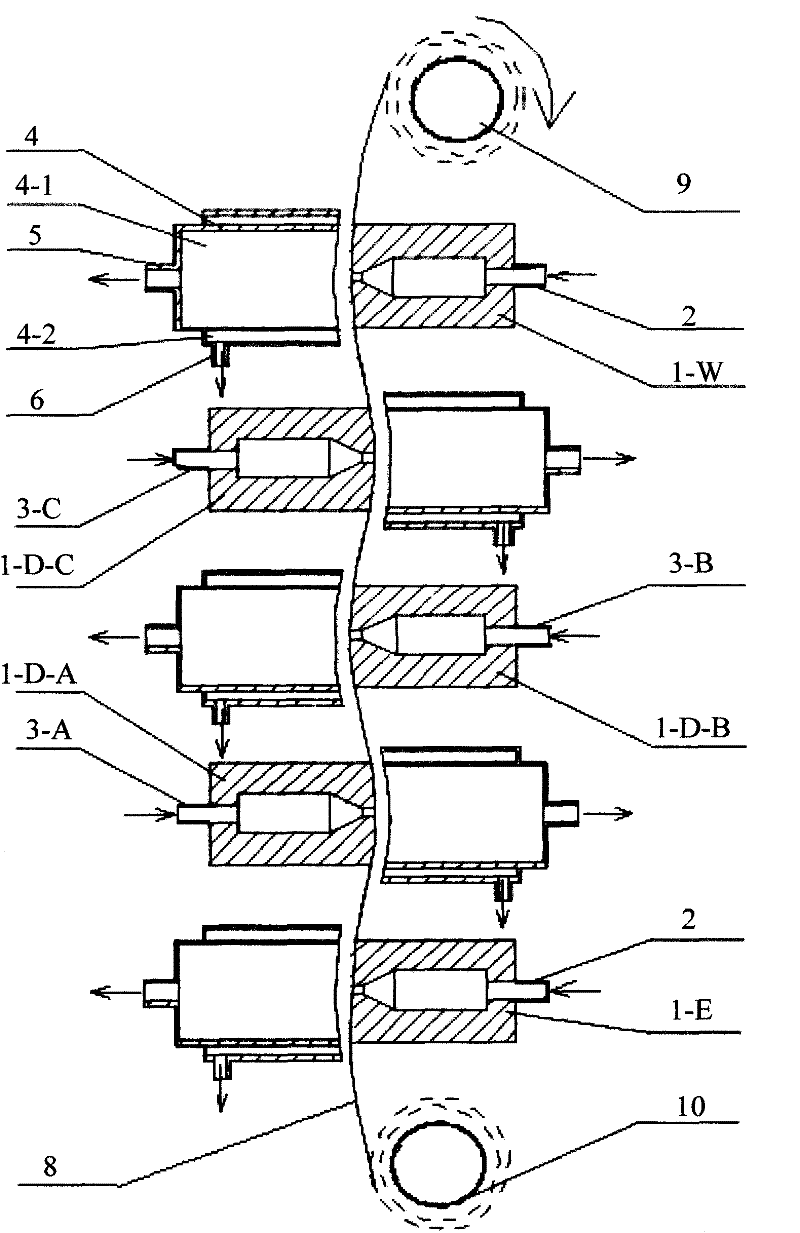

[0036] Embodiment three, such as image 3 Shown:

[0037] Its spraying principle and device flow are the same as those in Embodiment 2, except that each nozzle group 1-E to 1-W of the device and the corresponding used fluid recoverer 4 face the nozzle surface of the dyed object 8 It is made into an arc shape, and the dyed object 8 slides over the surface of the nozzle orifice of each nozzle group 1-E to 1-W when it runs along the track of the dyeing process, and is completed under the guidance and tension of the smooth surface of the nozzle orifice. Dyeing process, so as to realize the self-guiding and tensioning of the dyed object 8, the guide roller 7 in the second embodiment is omitted to achieve the purpose of simplifying the structure, thereby realizing the double-sided spraying process of the supercritical fluid on the dyed object 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com