Method for modifying continuous multistage cotton and linen yarns

A hemp yarn, multi-station technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, textile processing machine accessories, etc., can solve problems such as rough hand, poor dyeability, easy wrinkling, etc., to improve dyeing performance , The effect of fast heating and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

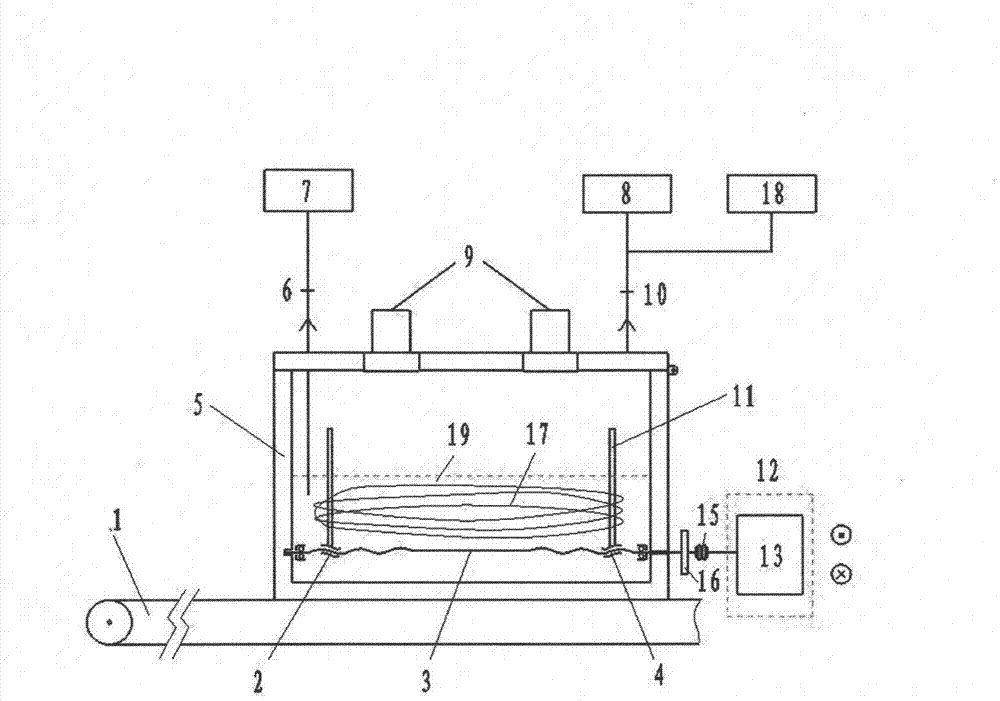

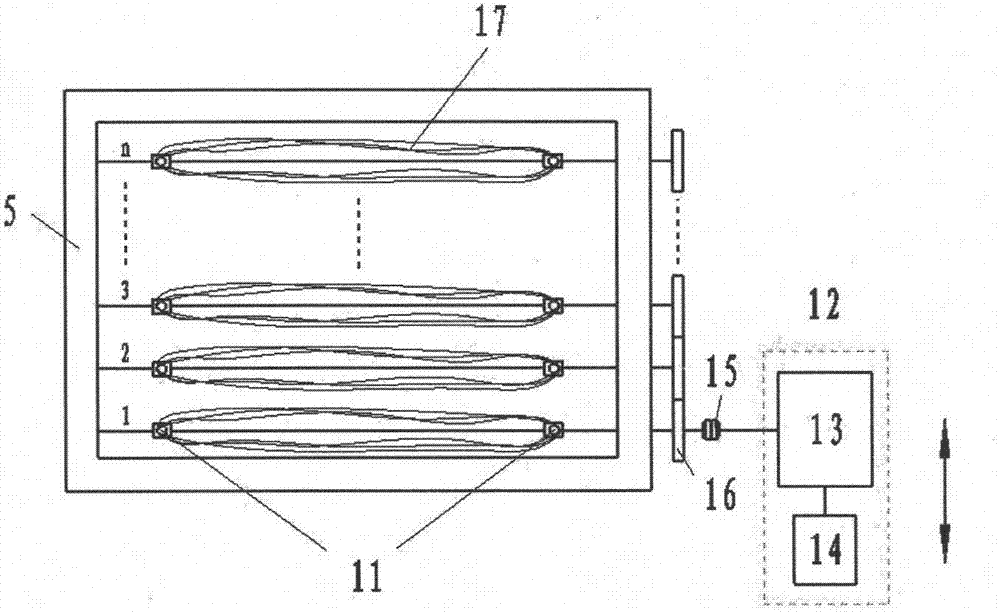

[0029] Such as figure 1 As shown, it is a schematic structural diagram of a continuous multi-station cotton and linen yarn modification device, and the continuous multi-station cotton and linen yarn modification device is located at a station in the continuous multi-station modification process, including The conveyor belt 1 is provided with a processing box 5 on the conveyor belt 1. The processing box 5 is an openable airtight container. The upper end cover of the processing box 5 is provided with two microwave generating devices 9, a first quick connector 6 and a second quick connector 10, the first quick connector 6 can be connected with the liquid ammonia delivery system 7 located above the designated station of the treatment box 5, and the second quick connector 10 can be connected with the ammonia delivery system 8 and the ammonia gas delivery system located above the designated station of the treatment box 5. Atmospheric conveying system 18 is connected, and processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com