Flax roving supercritical CO2 biological enzyme bleaching device and bleaching method thereof

A CO2, supercritical technology, applied in sustainable manufacturing/processing, textile/flexible product manufacturing, textile and papermaking, etc., can solve problems such as high energy consumption and high pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The structure of the bleaching kettle used in the following examples is the supercritical carbon dioxide cheese dyeing kettle in the Chinese patent whose publication number is CN102787459A, such as the dyeing kettle structure described in Example 1 in the publication.

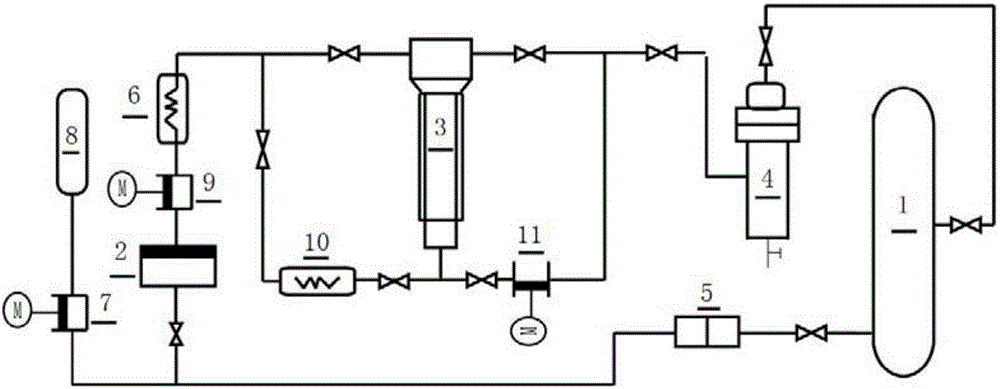

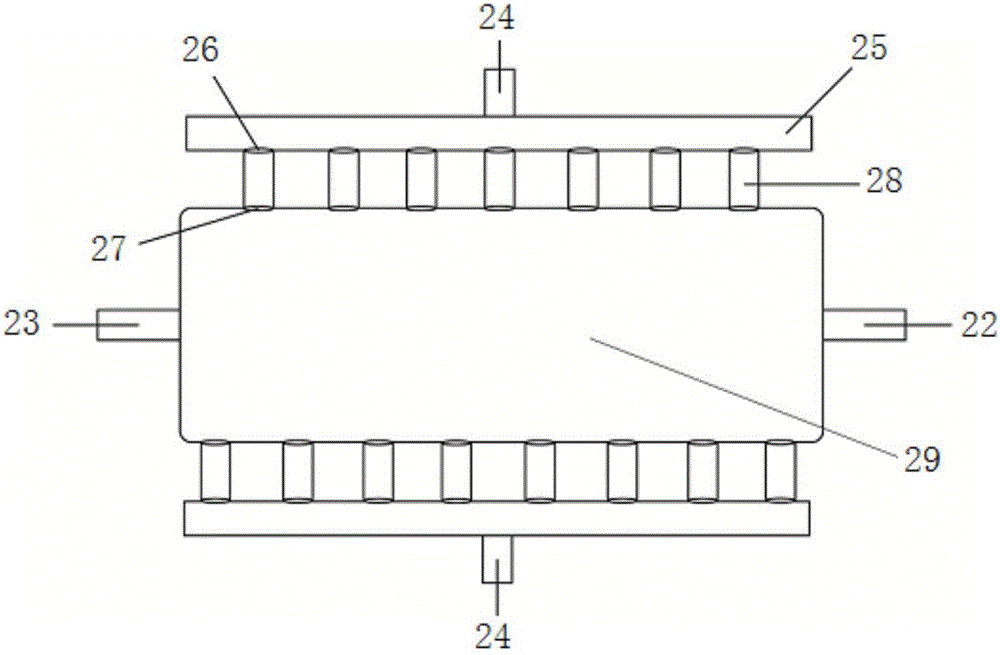

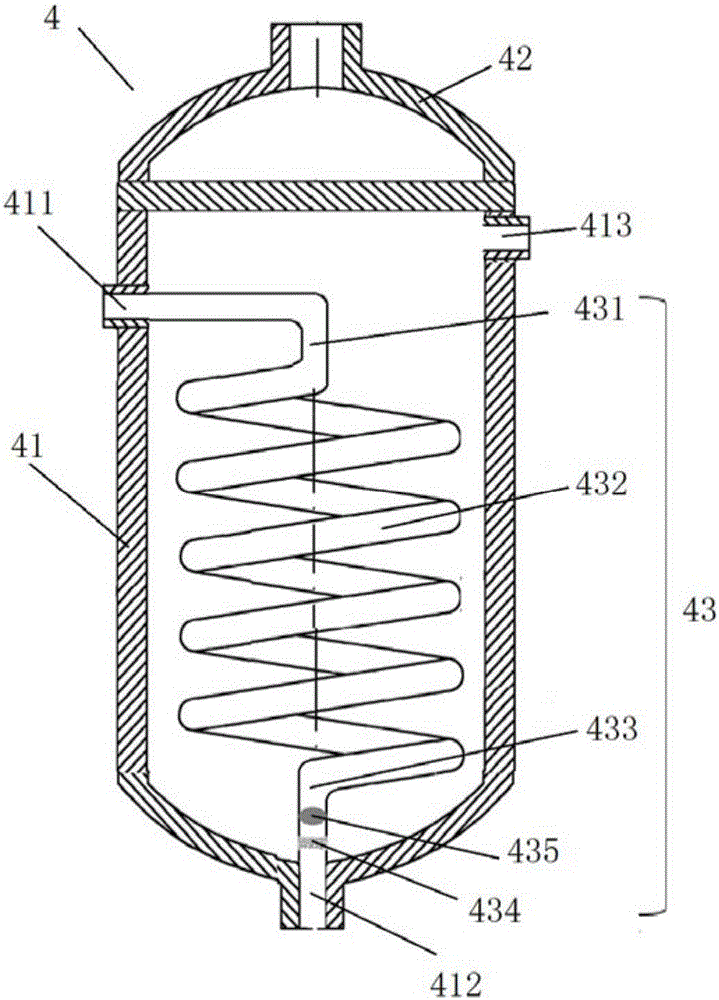

[0029] combined with Figure 1-3 , to illustrate the supercritical carbon dioxide bleaching device and bleaching process of the present invention.

[0030] Supercritical carbon dioxide bleaching device of the present invention, as figure 1 shown, including CO 2 Tanks, Filters, Blenders, CO 2 booster pump, preheater, heater, bleaching tank, separation tank, auxiliary solvent tank, liquid delivery pump and magnetic circulation pump, wherein the CO 2 Tanks, Filters, Blenders, CO 2 The booster pump, preheater, bleaching tank, and separation tank are connected in sequence through...

Embodiment 2

[0040] According to the supercritical carbon dioxide bleaching device described in embodiment 1 and working principle, the flax roving is bleached, comprising the steps:

[0041] (1) Preparation of biological enzyme bleaching agent:

[0042] Mix 0.5% (o.w.f.) xylanase and 1% (o.w.f.) glucose oxidase, dissolve them in water, prepare a mixed solution with a concentration of 1 wt%, and obtain a biological enzyme bleaching agent, stir evenly and set aside;

[0043] (2) 10kg flax roving bobbins are placed in the bleaching kettle, and the biological enzyme bleaching agent is placed in the cosolvent tank;

[0044] (3) Turn on the refrigeration system, liquid CO 2 in CO 2 It flows out of the storage tank, and the biological enzyme bleach in the co-solvent tank is injected into the co-solvent inlet of the blender under the action of the liquid delivery pump, and enters the inlet of the pinhole conveyor through the co-solvent channel, and passes through the pinhole conveyor in the pin...

Embodiment 3

[0047] According to the supercritical carbon dioxide bleaching device described in embodiment 1 and working principle, the flax roving is bleached, comprising the steps:

[0048] (1) Preparation of biological enzyme bleaching agent:

[0049] Mix 0.2% (o.w.f.) xylanase and 1.5% (o.w.f.) glucose oxidase, dissolve in water, configure a mixed solution with a concentration of 1.5wt%, to obtain a biological enzyme bleaching agent, stir evenly and set aside;

[0050] (2) 12kg flax roving bobbins are placed in the bleaching kettle, and the biological enzyme bleaching agent is placed in the cosolvent tank;

[0051] (3) Turn on the refrigeration system, liquid CO 2 in CO 2 It flows out of the storage tank, and the biological enzyme bleach in the co-solvent tank is injected into the co-solvent inlet of the blender under the action of the liquid delivery pump, and enters the inlet of the pinhole conveyor through the co-solvent channel, and passes through the pinhole conveyor in the pinh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com