Supercritical fluid dyeing machine

A supercritical fluid and dyeing machine technology, which is applied in dyeing method, solvent dyeing, textile processing machine accessories, etc., can solve the design requirements and difficulty of increasing the system and circulating pump, the difficulty of sealing and sealing device durability, and the difficulty of obtaining uniformity Guarantee and other issues to achieve the effect of solving the generation and discharge of pollutants, reducing equipment manufacturing costs and system sealing and design requirements, and improving level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

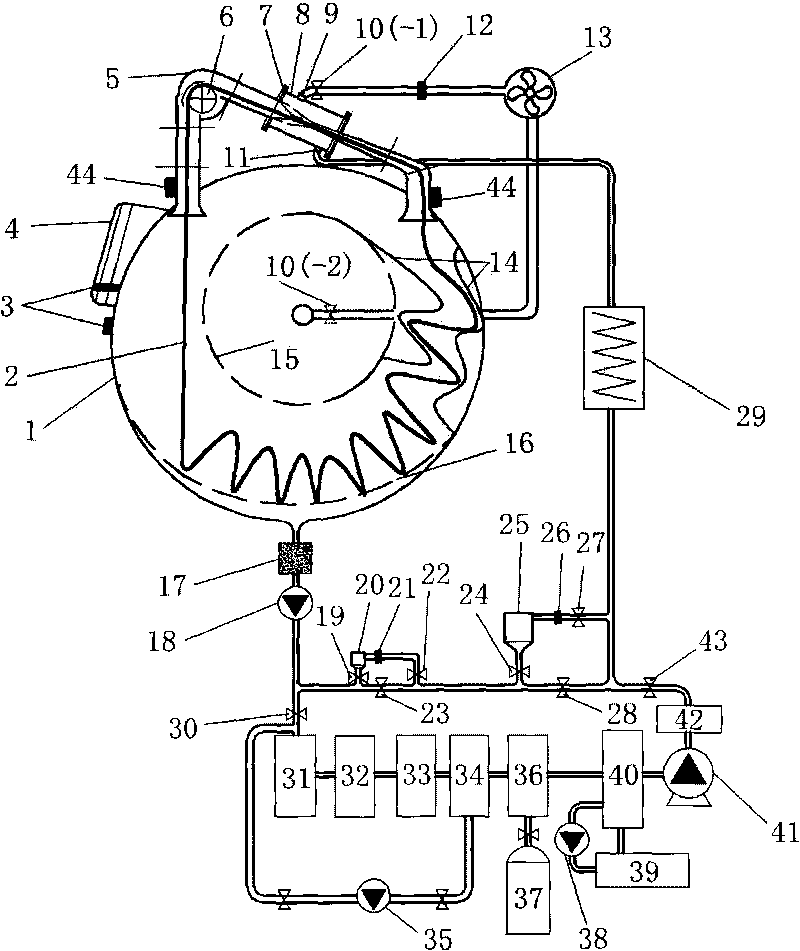

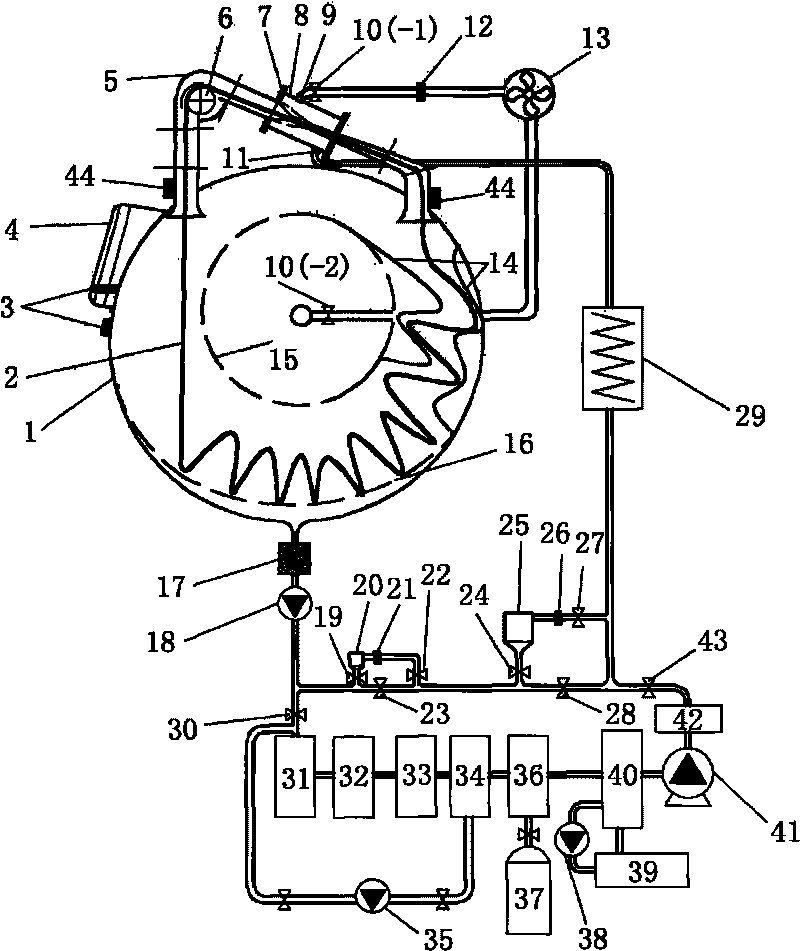

[0022] Such as figure 1 As shown, the supercritical fluid dyeing machine of the present invention includes a supercritical fluid dyeing tank, a fabric circulation loop and a dyeing fluid circulation system.

[0023] The supercritical fluid dyeing kettle has a horizontal cylindrical high-pressure dyeing kettle as the kettle body 1, an operating port 4 is opened above the kettle body, and a fluid outlet is opened below the kettle body, through the pipeline and the fluid filtering device 17, Connect the dyeing fluid circulation system after the circulation pump 18 is connected;

[0024] The fabric circulation circuit includes the cloth storage tank inside the dyeing kettle and the wave-shaped cloth guiding channel, as well as the cloth rope lifting device and traction device above the dyeing kettle; the cloth storage tank is a cylindrical Parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com