Ejector for supercritical fluid jet dyeing

A supercritical fluid and ejector technology, used in solvent dyeing, textile material processing equipment configuration, etc., can solve the problems of fast jet pressure drop, restricting popularization and application, complex structure, etc., to eliminate deformation and tension damage, and increase dyeing area. , Solve the effect of excessive pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

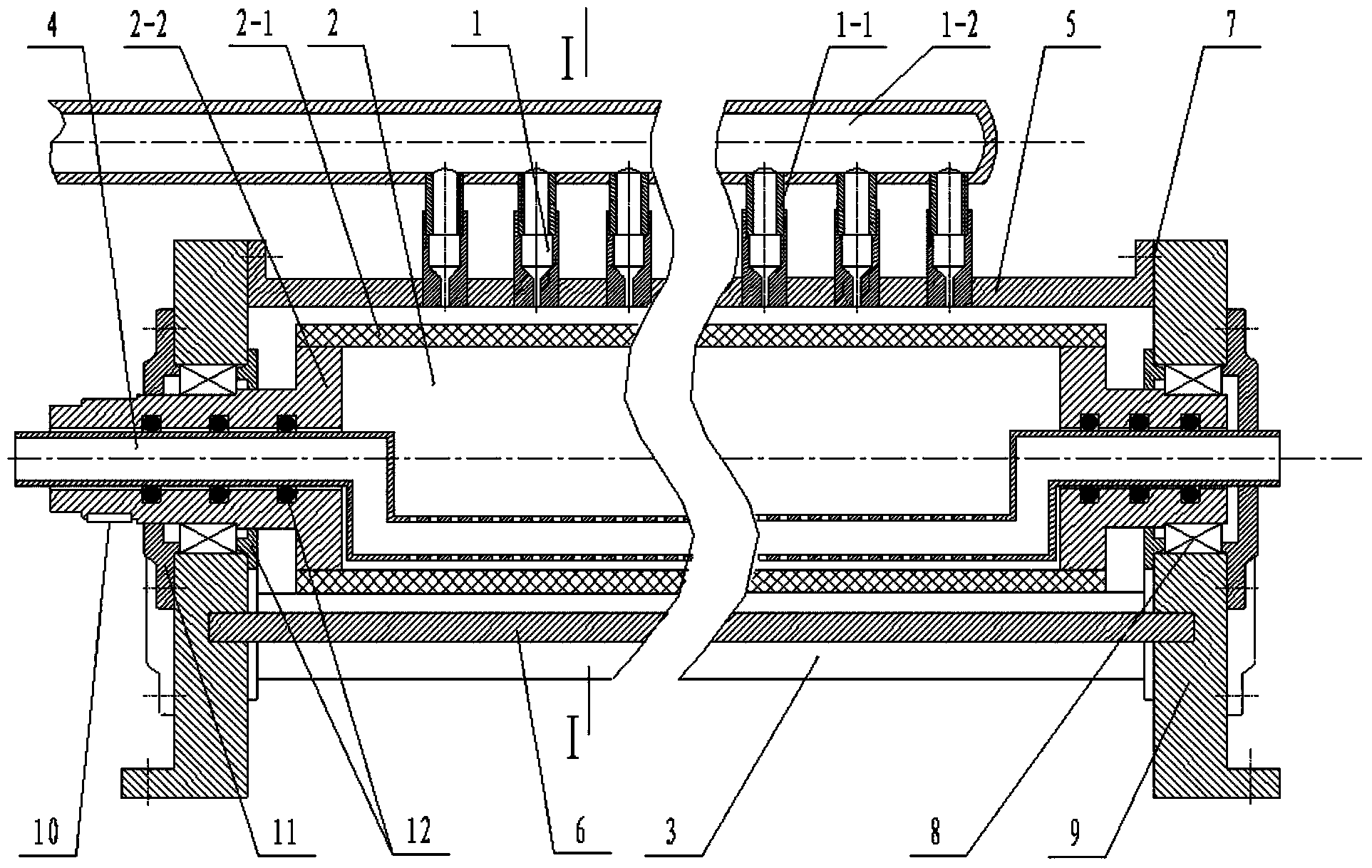

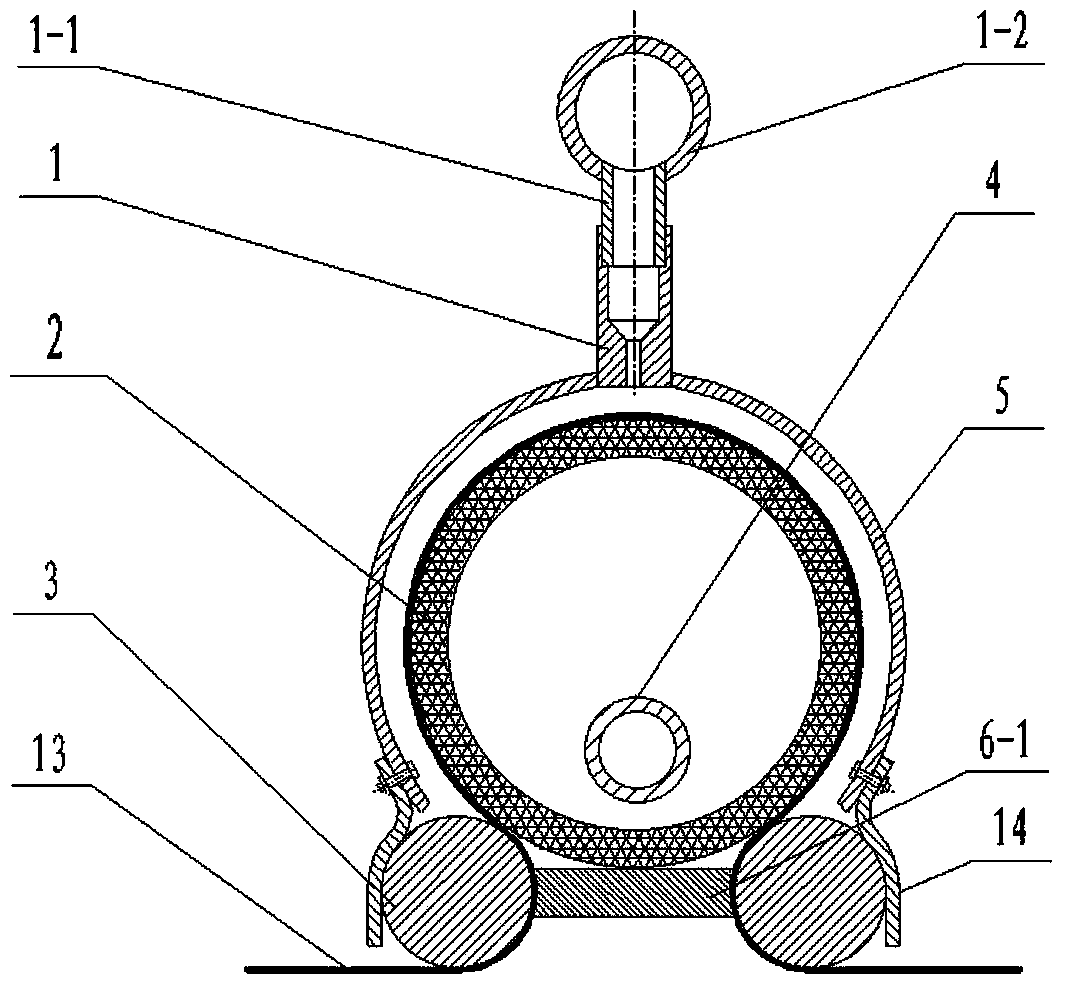

[0026] Embodiment one, the embodiment of supercritical fluid jet dyeing injector, as figure 1 , figure 2 , image 3 shown.

[0027] It consists of nozzle 1, nozzle branch pipe 1-1, nozzle main pipe 1-2, cloth dyeing roller 2, return pipe 4, cloth guide roller 3, fairing 5, baffle plate 14, overflow barrier 6 and side wall plate 9.

[0028] The cloth dyeing roller 2 is made up of a porous cylinder 2-1 and a hollow journal 2-2. The hollow journal 2-2 is coaxially installed at both ends of the porous cylinder 2-1, and the inner hole of the hollow journal 2-2 Return pipe 4 is installed, and the endoporus of hollow journal 2-2 is sealed with seal 12 with backflow pipe 4 matching positions; The hollow journal 2-2 of cloth dyeing roller 2 two ends is installed on the side wall plate 9 by bearing 8, and Install the transmission gear or sprocket on the hollow journal 2-2 at one end through the key or spline 10; install the cloth guide roller 3 at the position parallel to the axis o...

Embodiment 2

[0030] Embodiment two, the implementation process of the supercritical fluid dyeing injector device of single-side spraying, such as Figure 5 and Figure 8 shown.

[0031] Each injector is distributed along the same side of the object to be dyed 13, and along the direction in which the object to be dyed 13 travels, the cleaning injector 20, the dyeing injector 21 and the rinsing injector 22 are arranged successively, wherein the number of dyeing injectors 22 can be determined according to the specific dyeing process. One or more are required; each injector is installed on the frame 16 through the foundation of the bolt 7 and the side wall plate 9, and the tension wheel 15 is installed through the frame 16 between each injector.

[0032] Along the direction of travel of the dyed object 13, the nozzles 1 of the first injector are collected from the nozzle branch pipe 1-1 to the nozzle main pipe 1-2 and then connected to the supercritical fluid generation subsystem 18, and the ...

Embodiment 3

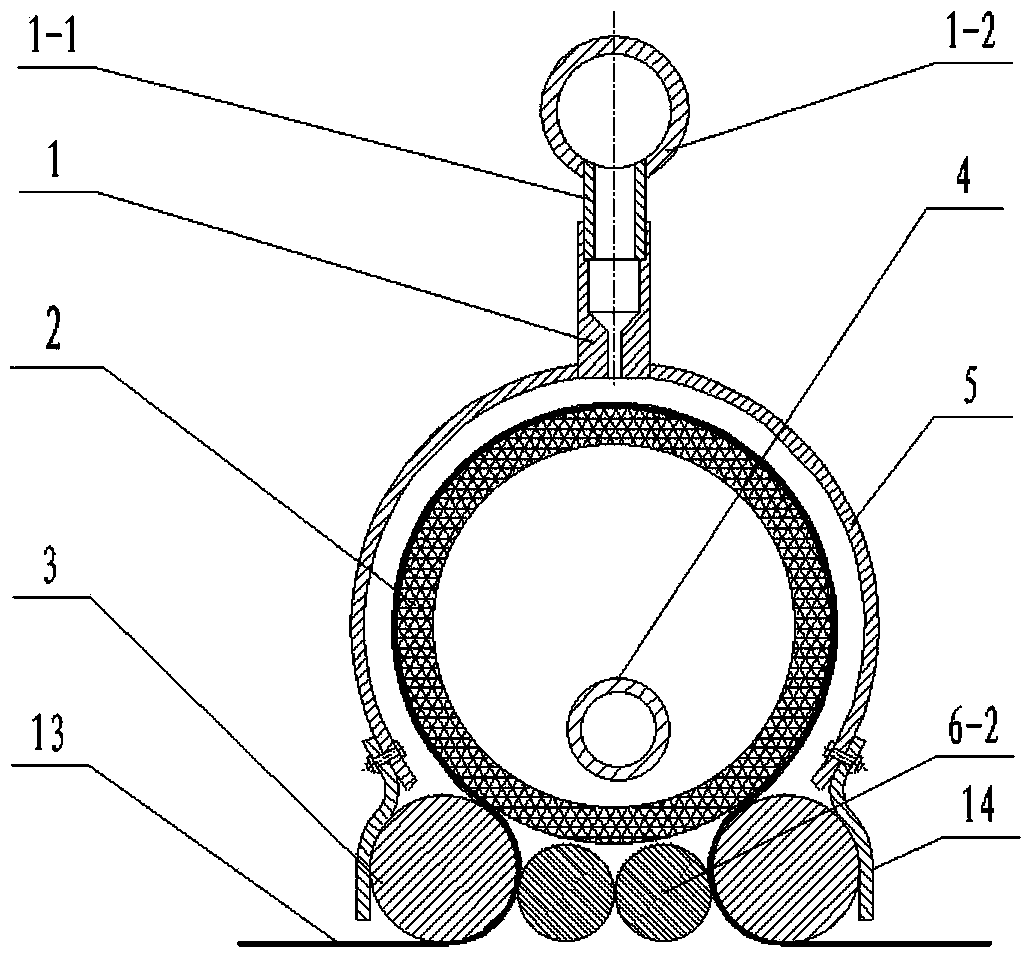

[0040] Embodiment three, the supercritical fluid spraying device of double-sided spraying, as Figure 6 , Figure 7 and Figure 8 shown.

[0041] In this embodiment, the structure of the single injector is the same as that of the first embodiment, and the way of connecting the single injector to other subsystems is the same as that of the second embodiment.

[0042] One or more injectors form a group, which are alternately distributed on both sides of the dyed object 13, and along the direction of the dyed object, the first group is cleaning injectors 20, the last group is rinsing injectors 22, and the middle groups are dyeing injectors. Injector 21, the quantity of dyeing injector 22 can be one or more groups according to specific dyeing process requirements; Each injector is installed on the frame 16 by the foundation of bolt 7 and side wall plate 9, and adjacent A tension wheel 15 is installed through a frame 16 between the outlet and inlet positions of the dyed matter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com