Supercritical carbon dioxide garment dyeing kettle and waterless dyeing method thereof

A technology of garment dyeing and carbon dioxide, which is applied in the field of textile printing and dyeing, can solve problems such as the inability to guarantee the level dyeing of white blank garments, difficulty in loading and unloading, and uneven contact area between dyeing liquor and garment fabrics, so as to improve the influence of fluid flow decay factors, The effect of short production cycle, improved uniformity and dye uptake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

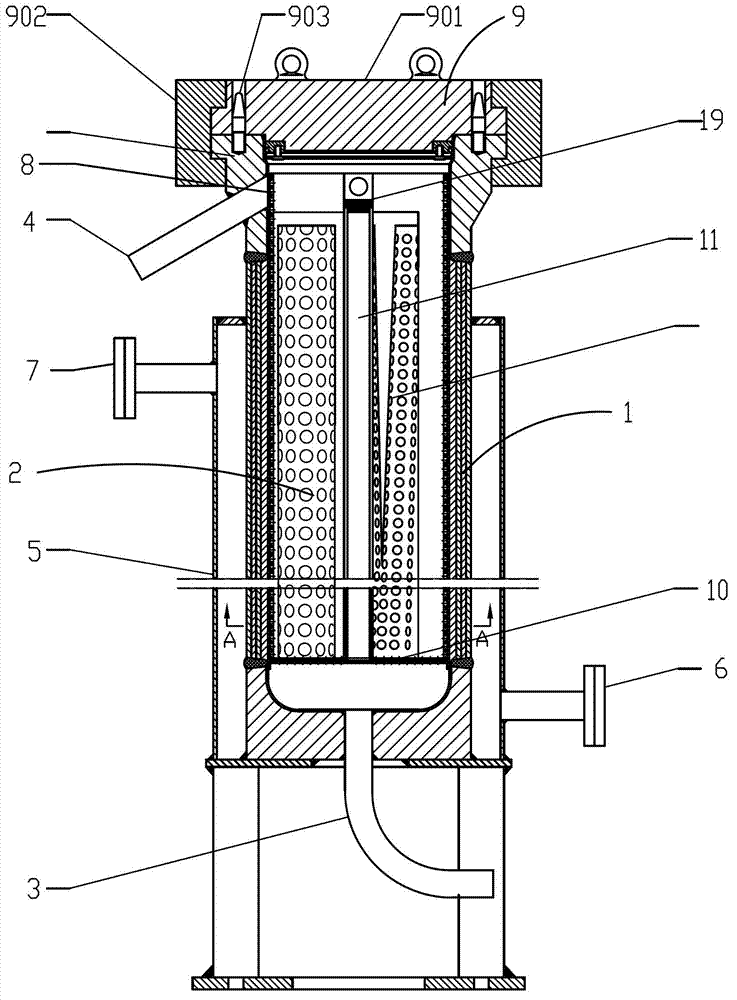

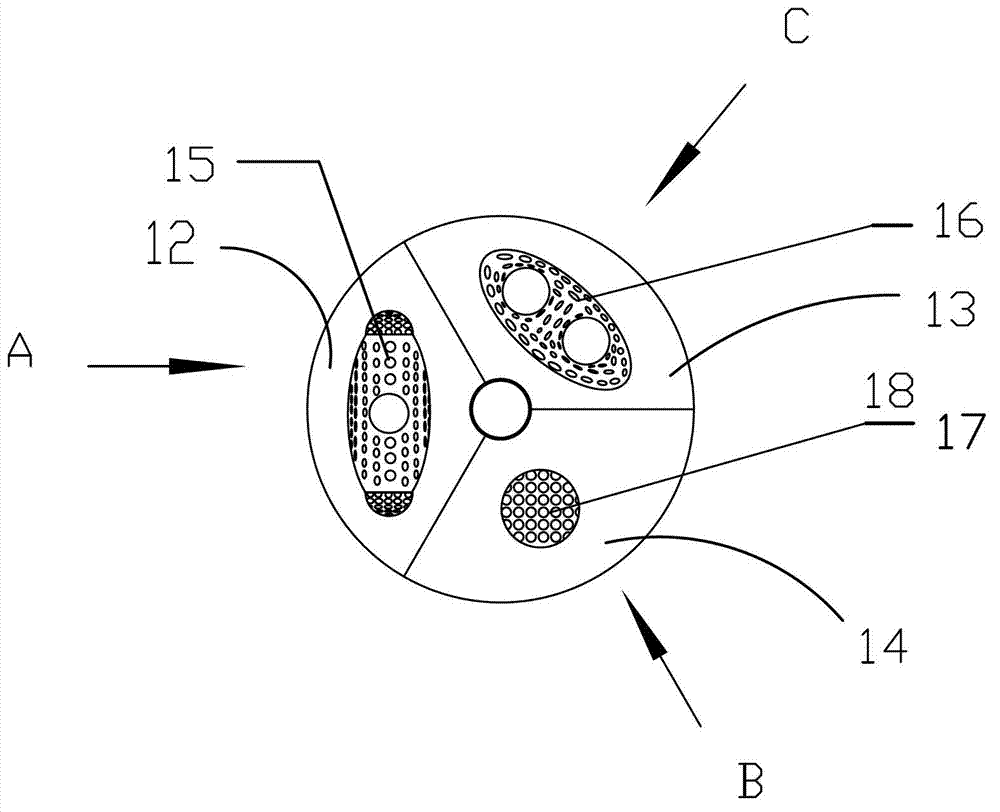

[0030] The present invention is described in conjunction with the accompanying drawings.

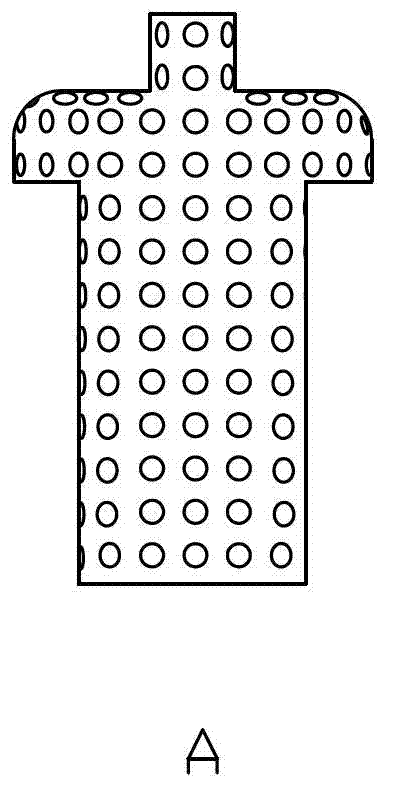

[0031] The supercritical carbon dioxide garment dyeing kettle of the present invention comprises a cylinder body 1 and a garment dyeing cylinder body 2, and the garment dyeing cylinder body 2 is fixed in the cylinder body 1; the upper end of the cylinder body 1 is equipped with a movable sealing cover 9, and the lower end is provided with a carbon dioxide fluid Outlet 3, the upper part of the cylinder body 1 is provided with a carbon dioxide fluid inlet 4; the outside of the cylinder body 1 is fixed with a heating jacket 5; the upper end of one side of the heating jacket 5 is provided with a heating medium outlet 6, and the lower end of the other side is provided with a heating medium Inlet 7; it is characterized in that the cylinder wall of the garment dyeing cylinder 2 is provided with a hole I8; the center of the bottom support plate 10 of the garment dyeing cylinder 2 is fixed with an...

Embodiment 2

[0034] Disperse red dye 5kg is placed in the dye still of supercritical carbon dioxide dyeing device. Use special equipment (such as an electric hoist), open the lifting ring of the dyeing cylinder in the dyeing kettle of the supercritical carbon dioxide dyeing device, and lift out the entire dyeing cylinder; open the dyeing basket, and move 10 polyester-cotton blended white T-shirts and polyester blanks 15 pairs of trousers and 15 woolen silk scarves, about 20kg in total, are evenly loaded into the dyeing basket. Then turn on the refrigeration system, pressurize the liquid carbon dioxide to above the critical pressure, and then heat the high-pressure liquid carbon dioxide to above the critical point temperature through the heat exchanger, that is, the carbon dioxide reaches the critical state. Supercritical carbon dioxide enters the dye kettle pre-installed with dye, and the supercritical fluid with dye passes through the dye kettle to make the device reach the target process...

Embodiment 3

[0036] Reactive blue dye 4kg is placed in the dye still of supercritical carbon dioxide dyeing device. Use special equipment (such as an electric hoist), open the lifting ring of the dyeing cylinder in the dyeing kettle of the supercritical carbon dioxide dyeing device, and lift the entire dyeing cylinder; open the dyeing basket, and put 20 pieces of polyester sweaters, 30 pieces of pure cotton sports pants, 30 wool knitted scarves and 25 pairs of nylon elastic stockings, about 40kg in total, are evenly loaded into the dyeing basket. Then turn on the refrigeration system, pressurize the liquid carbon dioxide to above the critical pressure, and then heat the high-pressure liquid carbon dioxide to above the critical point temperature through the heat exchanger, that is, the carbon dioxide reaches the critical state. Supercritical carbon dioxide enters the dye kettle pre-installed with dye, and the supercritical fluid with dye passes through the dye kettle to make the device reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com