Dyeing process of blended fabric

A blended fabric and process technology, applied in dyeing, textile and papermaking, physical treatment, etc., can solve the problems of large color difference in fabric dyeing, low color fastness, low color fastness, etc., to improve uniformity and color fastness Degree, the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

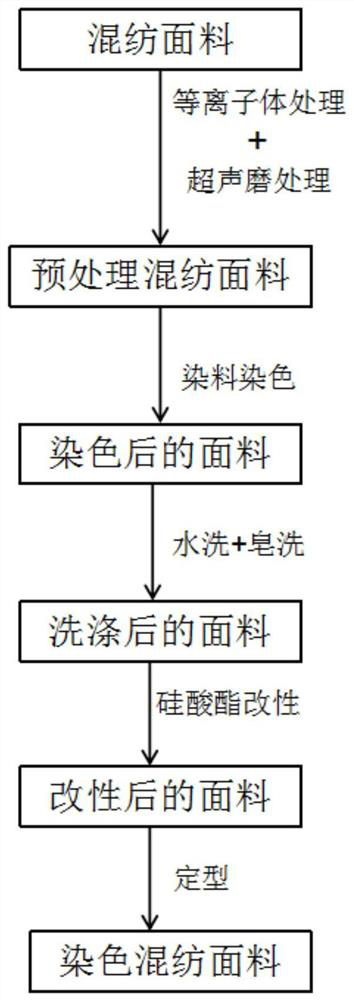

Method used

Image

Examples

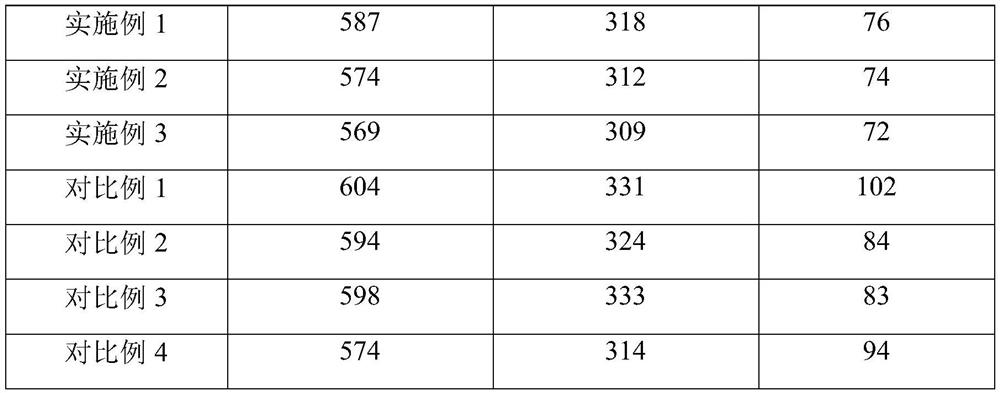

Embodiment 1

[0037] 1. Blend polyester, acrylic and spandex in a ratio of 60:30:10 by knitting to obtain a blended fabric.

[0038] 2. Put the mixed fabric in the plasma cleaning machine, set the atmosphere to air atmosphere, the temperature is 25 ℃, and perform plasma treatment for 5 minutes to obtain the treated fabric, and then soak the treated blended fabric in 120g / L containing titanium dioxide nanoparticles Ultrasonic treatment was carried out in the aqueous solution of 3 h (ultrasonic power was 600W) to obtain the pretreated fabric.

[0039]3. Mix ethanol and water according to the volume ratio of 3:12, then the concentration of sodium sulfate is 75g / L, the concentration of sodium carbonate is 4g / L, the concentration of polyoxyethylene laurate is 6g / L, and the polyoxyethylene laurate is 6g / L. Ethylene glycol dioleate 12g / L, the above components were added to the mixed solvent of ethanol and water in turn, stirred to dissolve, then added safflower pigment to it according to the dye c...

Embodiment 2

[0045] The blended fabric is the same as Example 1.

[0046] 1. Put the mixed fabric in the plasma cleaning machine, set the atmosphere to air atmosphere, the temperature is 25 °C, and perform plasma treatment for 6 minutes to obtain the treated fabric, and then soak the treated blended fabric in 100g / L containing titanium dioxide nanoparticles. Ultrasonic treatment was carried out in the aqueous solution of 4h (ultrasonic power was 700W) to obtain the pretreated fabric;

[0047] 2. Mix ethanol and water according to the volume ratio of 3:12, then the concentration of sodium sulfate is 85g / L, the concentration of sodium carbonate is 2g / L, the concentration of polyoxyethylene laurate is 5g / L, and the polyoxyethylene laurate is 5g / L. Ethylene glycol dioleate 10g / L, the above components were added to the mixed solvent of ethanol and water in turn, stirred to dissolve, then safflower pigment was added to it according to the dye concentration 10% owf, heated to 50 ° C, stirred and ...

Embodiment 3

[0053] The blended fabric is the same as Example 1.

[0054] 1. Put the mixed fabric in the plasma cleaning machine, set the atmosphere to air atmosphere, the temperature is 25 ℃, and carry out plasma treatment for 8 minutes to obtain the treated fabric, and then soak the treated blended fabric in 150g / L containing titanium dioxide nanoparticles Ultrasonic treatment is carried out in the aqueous solution of 2h (ultrasonic power is 800W) to obtain the pretreated fabric;

[0055] 2. Mix ethanol and water according to the volume ratio of 3:12, then the concentration of sodium sulfate is 65g / L, the concentration of sodium carbonate is 5g / L, the concentration of polyoxyethylene laurate is 8g / L, and the polyoxyethylene laurate is 8g / L. Ethylene glycol dioleate 14g / L, the above components were added to the mixed solvent of ethanol and water in turn, stirred to dissolve, then added safflower pigment according to the dye concentration 14% owf, heated to 50 ° C, stirred and mixed. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com