A method of ammonification modification of ramie fiber and its application method in liquid ammonia solvent dyeing

A ramie fiber modification technology, which is applied in the ammonification modification field of ramie fiber, achieves the effects of reducing environmental pollution, shortening dyeing time, and solving uneven color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Pretreatment of ramie fiber: choose ramie yarn for ramie fiber, put 200mL of ramie yarn into 200mL NaOH solution with a concentration of 15%, heat it to 50°C, keep it warm for 4h, and wash it with tap water until the eluate When the pH is 7.6, the pretreated yarn is obtained.

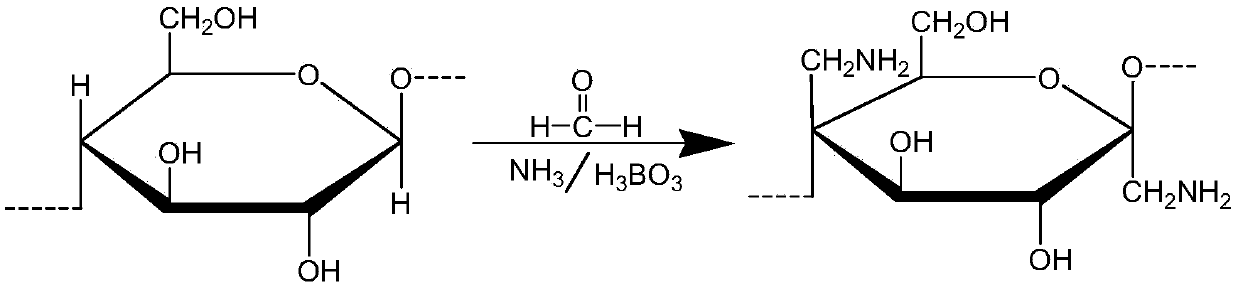

[0027] (2) Modification method: add 10mL formaldehyde, 1mL boric acid and 150mL deionized water into a 250ml three-necked flask, stir evenly, add the 1g ramie yarn after the pretreatment of step (1), and raise the reaction temperature to 40 ℃, then feed ammonia gas, reflux and stir the reaction for 3 hours, after the reaction is completed, take out the yarn, wash it with deionized water, and dry the yarn when the pH of the eluate is 6-7, and the ammoniated modified Sexual ramie yarn.

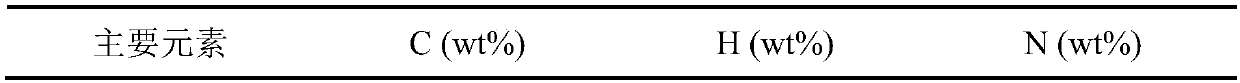

[0028] (3) Elemental analysis of the modified yarn and the unmodified yarn was performed, and the following results were obtained:

[0029]

[0030] From the elemental analysis results, it can be seen that...

Embodiment 2

[0035] (1) Pretreatment of ramie fiber: choose ramie yarn for ramie fiber, put 200mL of ramie yarn into 200mL NaOH solution with a concentration of 15%, heat it to 50°C, keep it warm for 4h, and wash it with tap water until the eluate When the pH is 7.3, the pretreated yarn is obtained.

[0036] (2) Modification method: add 12mL formaldehyde in 250ml three-necked flask, 1.5mL boric acid and 150mL deionized water, stir evenly, add the 1g ramie yarn after the pretreatment of step (1), temperature of reaction is raised to At 40°C, add ammonia gas, reflux and stir for 3 hours. After the reaction is completed, take out the yarn and rinse it with deionized water. When the pH of the eluate is 6-7, dry the yarn to obtain ammoniated product. Modified ramie yarn.

[0037] (3) Elemental analysis of the modified yarn and the unmodified yarn was performed, and the following results were obtained:

[0038]

[0039] From the elemental analysis results, it can be seen that after the ramie ...

Embodiment 3

[0044] (1) Pretreatment of ramie fiber: choose ramie yarn for ramie fiber, put 200mL of ramie yarn into 200mL NaOH solution with a concentration of 15%, heat it to 50°C, keep it warm for 4h, and wash it with tap water until the eluate When the pH is 7.1, the pretreated yarn is obtained.

[0045] (2) Modification method: add 12mL formaldehyde in 250ml three-necked flask, 1.5mL boric acid and 150mL deionized water, stir evenly, add the 1g ramie yarn after the pretreatment of step (1), temperature of reaction is raised to At 40°C, add ammonia gas, reflux and stir for 3 hours. After the reaction is completed, take out the yarn and rinse it with deionized water. When the pH of the eluate is 6-7, dry the yarn to obtain ammoniated product. Modified ramie yarn.

[0046] (3) Elemental analysis of the modified yarn and the unmodified yarn was performed, and the following results were obtained:

[0047]

[0048] From the elemental analysis results, it can be seen that after the rami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com