Dyeing process for dacron-spandex all-around elastic fabric

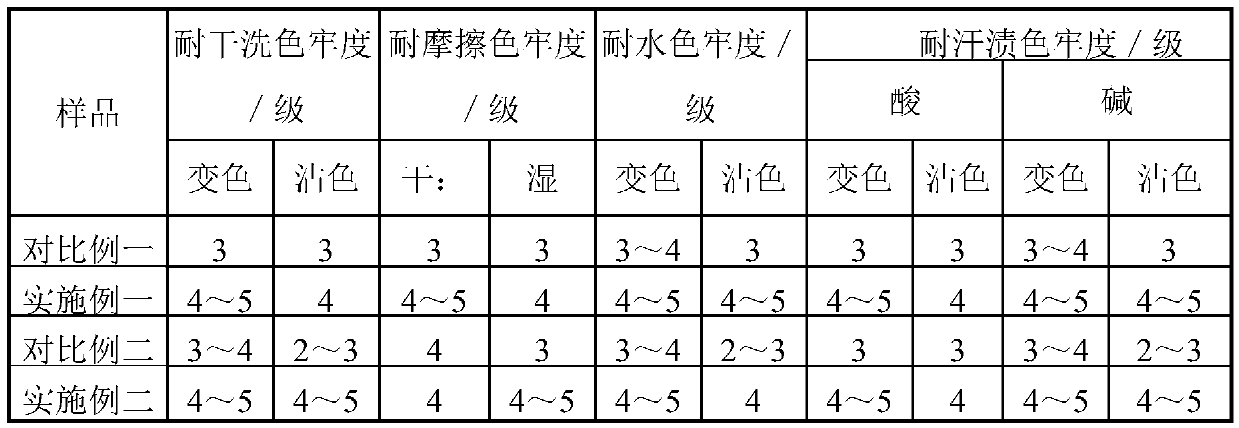

A four-sided elastic, fabric technology, applied in the field of textile fabric dyeing, can solve the problems of poor fastness, not washable, fabric color fastness can not meet the requirements, etc., to achieve good dyeing effect, no discoloration and color fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The dyeing process of a polyester-spandex four-way stretch fabric involved in this embodiment comprises the steps of: pre-dyeing the polyester-spandex four-way stretch fabric, dyeing the polyester-spandex four-way stretch fabric, reducing and cleaning the dyed fabric, and dyeing the polyester-spandex four-way stretch fabric. Foam hold for fabric.

[0015] In step S1 before dyeing, the polyester-spandex four-way stretch woven fabric is selected, the content of spandex is 15%-25%, and the warp and weft yarns are all polyester spandex core-spun yarns. The warp and weft yarns used in the selected polyester-spandex four-way stretch fabric are both 150D+40D.

[0016] Inject clean water according to the selected fabric at a bath ratio of 1:15, and add ULTRAVON TC, INVATEX CRA, INVADINELUN, INVATEX KR HC, RUCOGEN WBL, and caustic soda.

[0017] ULTRAVON TC is Huntsman's high-efficiency, multi-purpose detergent, dispersant and detergent with strong wetting performance. Low foa...

Embodiment 2

[0027]The dyeing process of a polyester-spandex four-way stretch fabric involved in this embodiment comprises the steps of: pre-dyeing the polyester-spandex four-way stretch fabric, dyeing the polyester-spandex four-way stretch fabric, reducing and cleaning the dyed fabric, and dyeing the polyester-spandex four-way stretch fabric. Foam hold for fabric.

[0028] In step S1 before dyeing, the polyester-spandex four-way stretch woven fabric is selected, the content of spandex is 15%-25%, and the warp and weft yarns are all polyester spandex core-spun yarns. The warp and weft yarns used in the selected polyester-spandex four-way stretch fabric are both 150D+40D.

[0029] Inject clean water according to the selected fabric at a bath ratio of 1:25, and add ULTRAVON TC, INVATEX CRA, INVADINELUN, INVATEX KR HC, RUCOGEN WBL, and caustic soda.

[0030] The added ULTRAVON TC is 1g / L, INVATEX CS is 1g / L, INVADINE LUN is 3g / L, INVATEXKR HC is 5g / L, RUCOGEN FWK is 2g / L, caustic soda is 20g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com