Supercritical carbon dioxide fluid dyeing device with two dye vats

A technology of carbon dioxide and liquid carbon dioxide, applied in solvent dyeing, textile material treatment, equipment configuration for textile material treatment, etc., can solve the problems of high energy consumption, single variety, low efficiency, etc., and achieve low overall cost and fast dyeing speed , The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

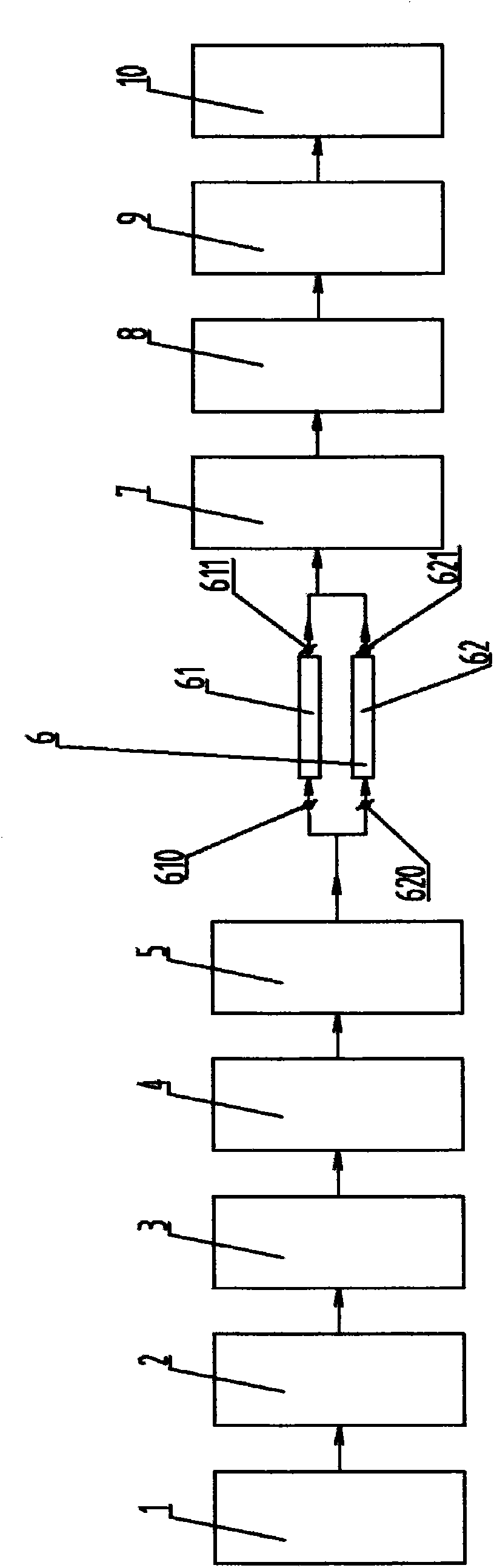

[0011] Such as figure 1 As shown, the present invention has a supercritical carbon dioxide fluid dyeing device with two dyeing vats, including a liquid carbon dioxide storage tank 1, a carbon dioxide injection high-pressure pump 2, a heater 3, a dye mixing tank 4, a mixed dye injection high-pressure pump 5, and a dyeing vat Group 6, decompression and temperature reduction device 7, separation kettle 8, condenser 9, and precision filter 10, characterized in that: the liquid carbon dioxide storage tank 1 is sequentially connected to the carbon dioxide injection high-pressure pump 2, heater 3, and dye mixing tank 4 , mixed dyes are injected into high-pressure pump 5, dyeing vat 6, decompression and cooling device 7, separating kettle 8, condenser 9, precision filter 10, and described dyeing vat group 6 has two dyeing vats, and each dyeing vat is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com