Diversified integrated dyeing device for supercritical carbon dioxide

A carbon dioxide and dyeing equipment technology, which is applied in solvent dyeing, textile material processing equipment configuration, liquid/gas/steam finished product processing, etc., can solve the problems of high equipment energy consumption, single variety, low efficiency, etc., and achieve low overall cost, Significant environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following non-limiting examples may enable those of ordinary skill in the art to more fully understand the present invention, but do not limit the present invention in any way.

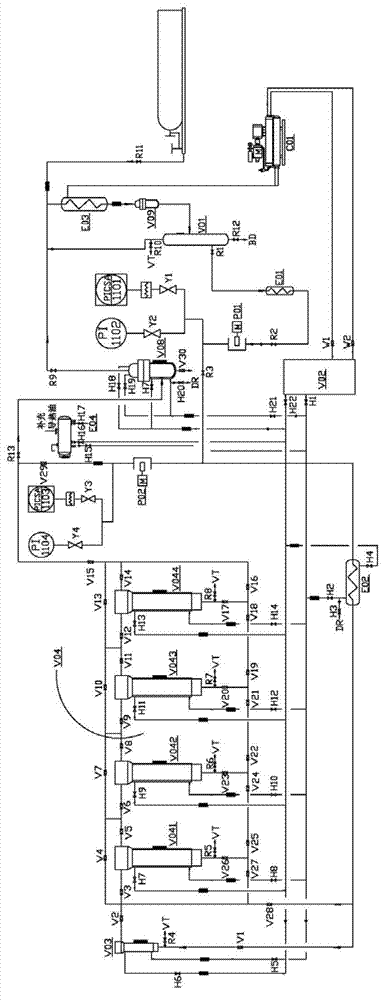

[0014] Attached to the following figure 1 Specific embodiments of the present invention will be described in detail.

[0015] figure 1 In the multiple integrated supercritical carbon dioxide dyeing equipment, the carbon dioxide storage tank V01 is connected to the high-pressure carbon dioxide main pump P01 through the condenser IE01; the high-pressure carbon dioxide main pump P01 is connected to the heat exchanger E02 that converts carbon dioxide into a supercritical state; The heat exchanger E02 is connected to the dye kettle V03 for dissolving the dye through pipelines; the dye kettle V03 is connected with the supercritical carbon dioxide that dissolves the dye to at least one dyeing kettle V04 that is connected with the dye kettle V03 to realize dyeing Middle; at least one dyed carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com