Cleaning method for supercritical carbon dioxide dyeing equipment

A technology of carbon dioxide and dyeing equipment, applied in chemical instruments and methods, detergent compositions, treatment of textile materials, etc., can solve the problems of poor color quality of dyed products, blockage of pipes, etc., and achieve non-corrosion, non-damage cleaning, comprehensive cost Low, environmentally significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

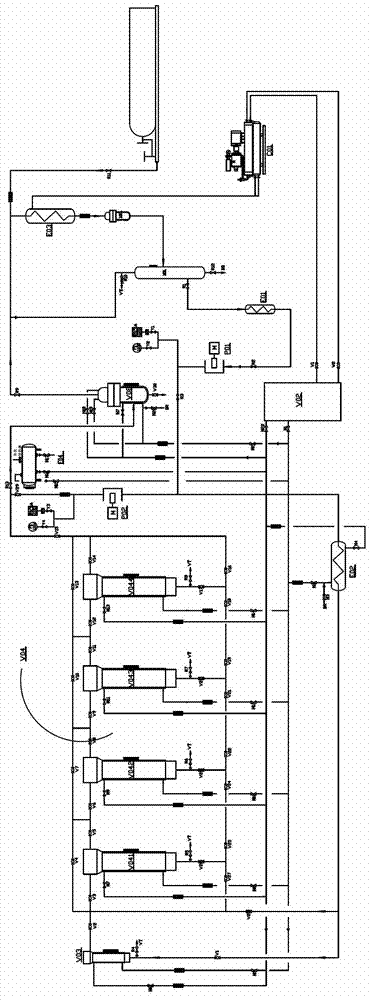

[0021] The following is attachedfigure 1 Multivariate integrated supercritical carbon dioxide dyeing equipment describes the specific implementation mode of the present invention in detail. The cleaning process of the present invention mainly adopts three steps of first cleaning, second cleaning and flushing.

[0022] The first cleaning: first use the inner path to clean the dyeing system pipeline and kettle body, add absolute ethanol and acetone solvents from the dye kettle before circulating cleaning, among them, the volume ratio of supercritical carbon dioxide, absolute alcohol and acetone is 100 : 2:1 mixing; liquid carbon dioxide is stored in the circulation storage tank, the liquid carbon dioxide is pressurized to 17MPa by the high-pressure pump during work, and then the high-pressure liquid carbon dioxide is heated to 80°C through the heat exchanger, and the carbon dioxide is transformed into a supercritical state; Open the relevant control valve and circulation pump to...

Embodiment 2

[0027] The following is attached figure 1 Multivariate integrated supercritical carbon dioxide dyeing equipment describes the specific implementation mode of the present invention in detail. The cleaning process of the present invention mainly adopts three steps of first cleaning, second cleaning and flushing.

[0028] The first cleaning: Firstly, the internal circulation path is used to clean the dyeing system pipeline and kettle body. Before cleaning, absolute ethanol and acetone solvents are added from the dye kettle. Among them, supercritical carbon dioxide, absolute ethanol and acetone are 100% by volume. : 2:1 mixing; liquid carbon dioxide is stored in the circulation storage tank, the liquid carbon dioxide is pressurized to 15MPa by the high-pressure pump during work, and then the high-pressure liquid carbon dioxide is heated to 70°C through the heat exchanger, and the carbon dioxide is transformed into a supercritical state; Open the relevant control internal circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com