Novel ejector used for supercritical fluid jet dying

A supercritical fluid and ejector technology, which is applied in solvent dyeing, equipment configuration for processing textile materials, etc., can solve the problems of dyeing dead zone of the dyed object, affecting the dyeing quality, etc., and achieves elimination of deformation and tension damage, excellent craftsmanship, and difficulty in The effect of dyed dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

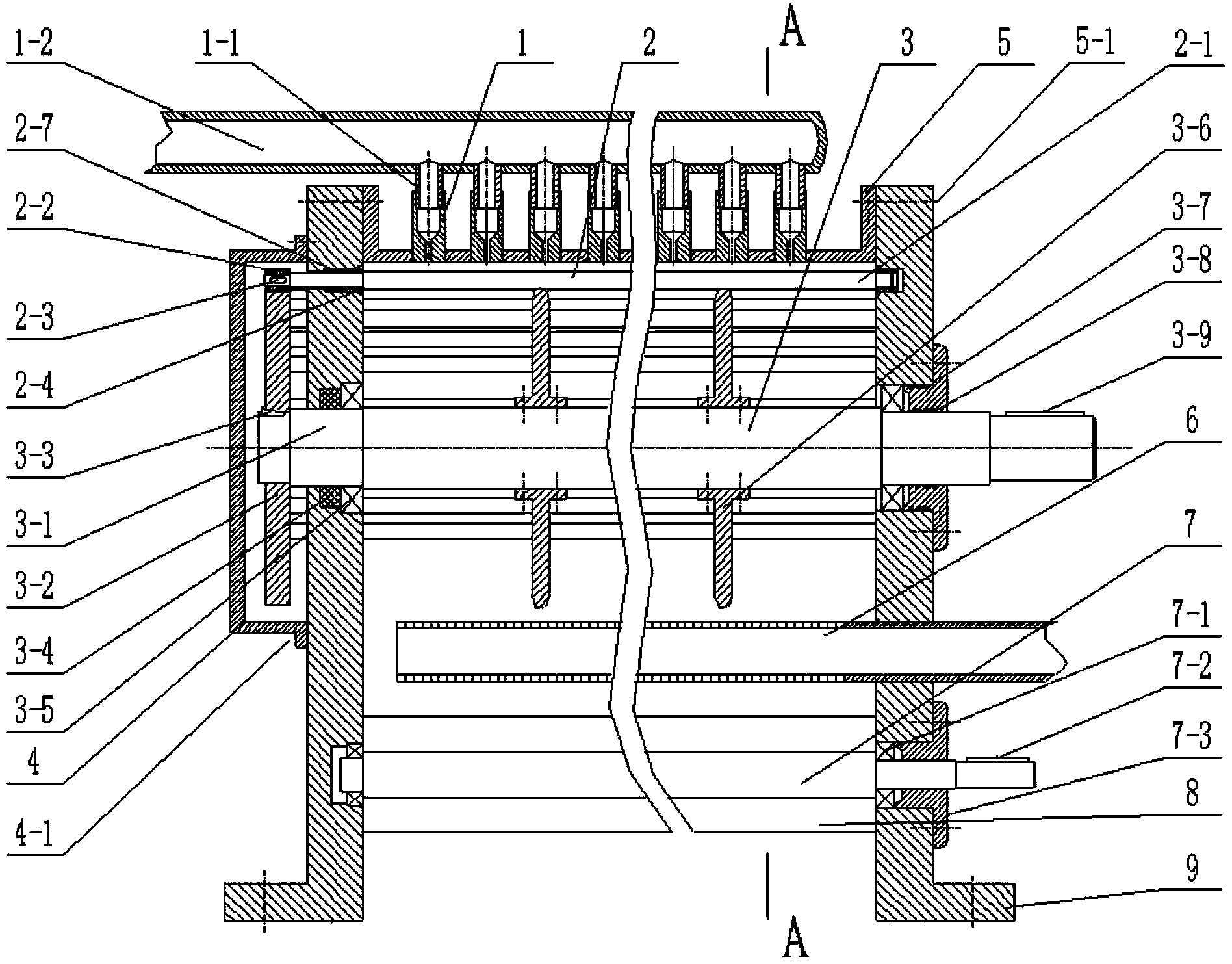

[0021] Embodiment one, the supercritical fluid jet dyeing injector when the gear drives the rolling washing roller, such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 shown.

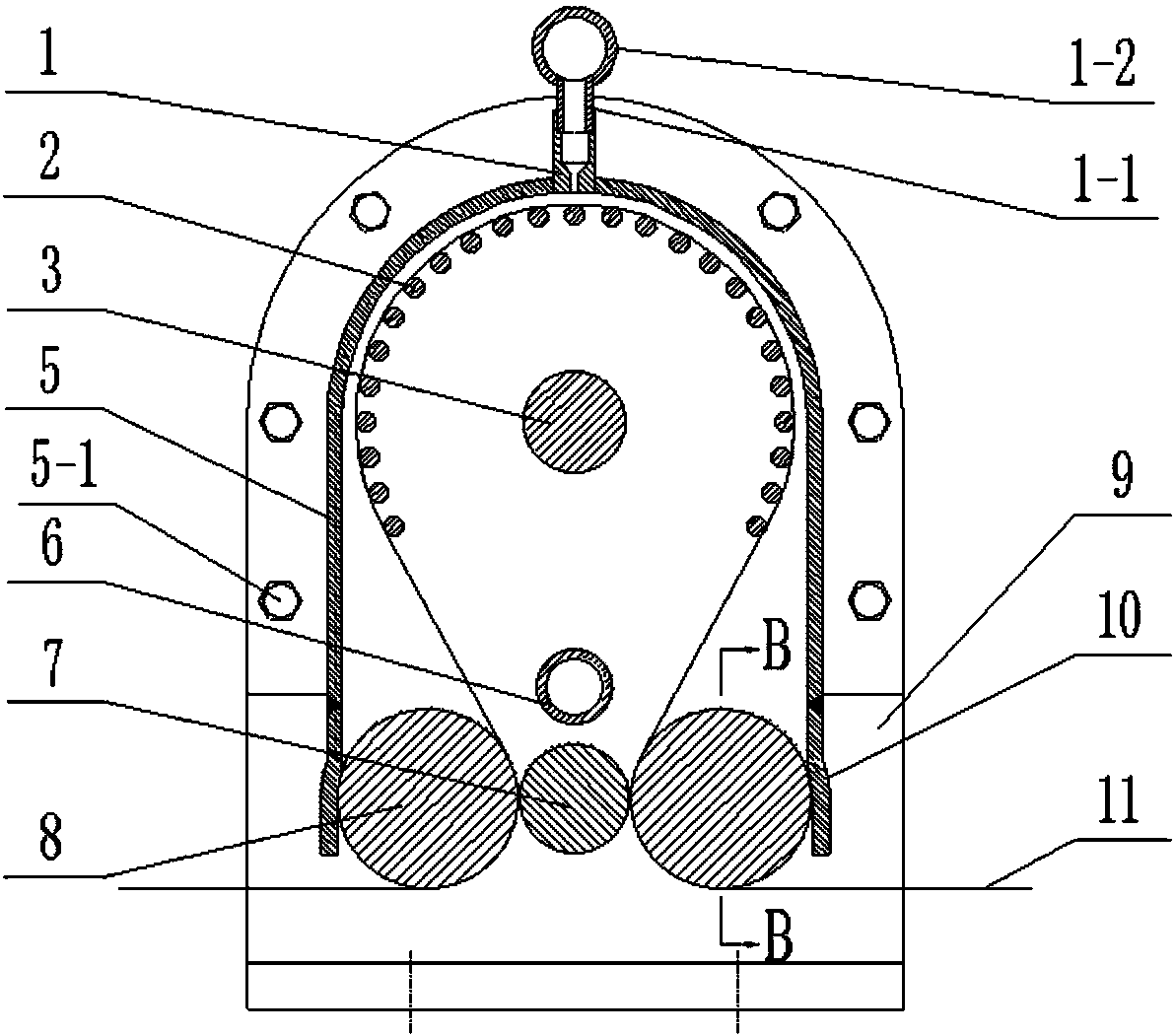

[0022] The injector described in this embodiment is composed of nozzle 1, nozzle branch pipe 1-1, nozzle main pipe 1-2, squirrel cage type washing and dyeing cylinder 2, transmission support rotor 3, sealing cover 4, fairing cover 5, return pipe 6, overflow resistance Roller 7, cloth guide roller 8, side wall plate 9, baffle plate 10 constitute.

[0023]Nozzle 1, nozzle branch pipe 1-1 and nozzle main pipe 1-2 are made of stainless steel. Nozzle 1 is a through-hole structure with the same hole diameter as that of nozzle branch pipe 1-1 and a hole diameter of 0.1-1 mm at one end. Nozzle 1 and nozzle branch pipe 1- 1 is fixedly connected by welding or threaded connection, the nozzle branch pipe 1-1 and the nozzle main pipe 1-2 are connected by welding; for the dyed object 11 with a widt...

Embodiment 2

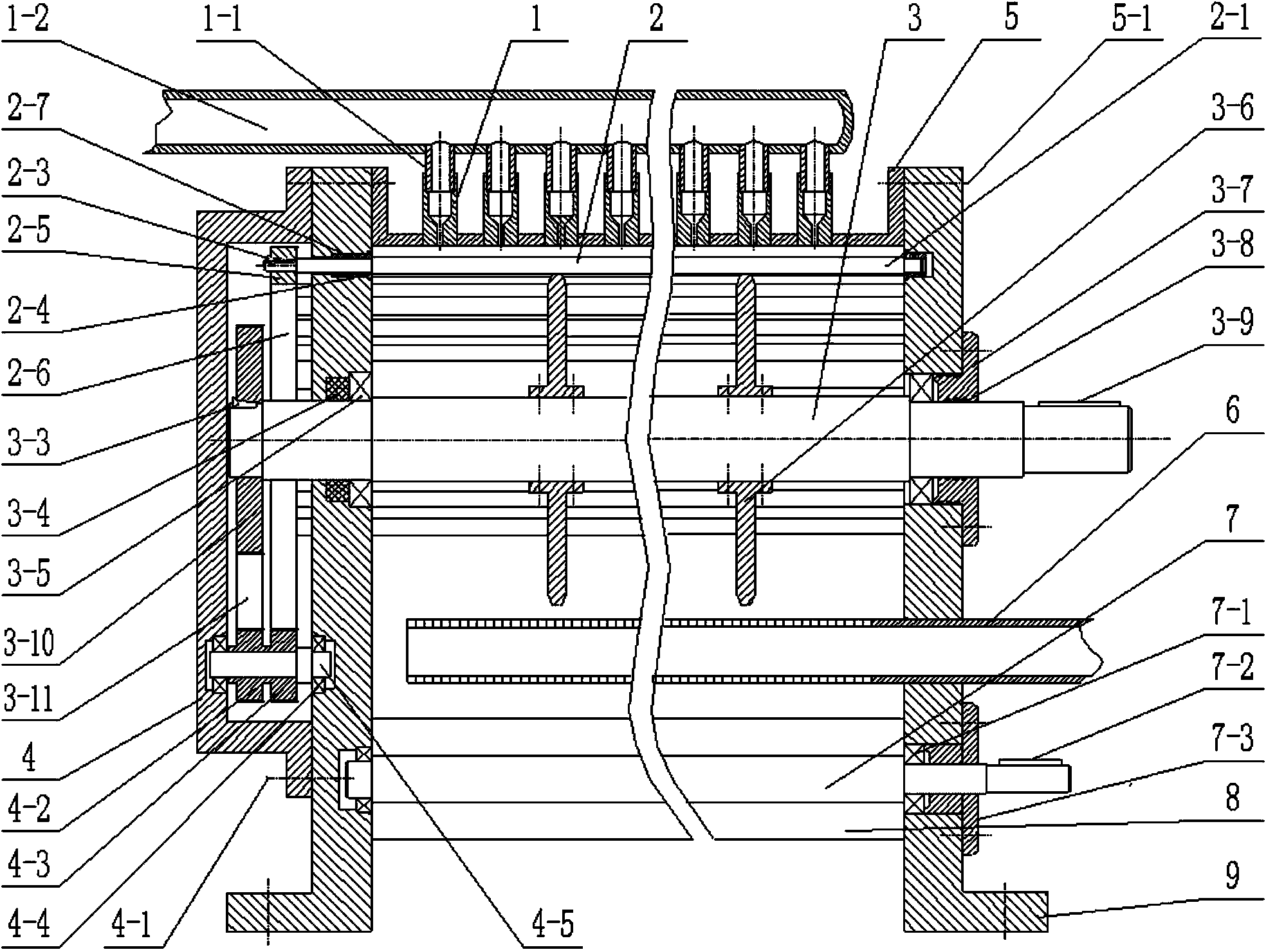

[0025] Embodiment two, when synchronous belt drives the injector of supercritical fluid spraying and dyeing when rolling dyeing roller, as figure 2 , image 3 , Figure 5 and Figure 6 shown.

[0026] The injector described in this embodiment is composed of nozzle 1, nozzle branch pipe 1-1, nozzle main pipe 1-2, squirrel cage type washing and dyeing cylinder 2, transmission support rotor 3, sealing cover 4, fairing cover 5, return pipe 6, overflow resistance Roller 7, cloth guide roller 8, side wall plate 9, baffle plate 10 constitute.

[0027] Nozzle 1, nozzle branch pipe 1-1 and nozzle main pipe 1-2 are made of stainless steel. Nozzle 1 is a through-hole structure with the same hole diameter as that of nozzle branch pipe 1-1 and a hole diameter of 0.1-1 mm at one end. Nozzle 1 and nozzle branch pipe 1- 1 The connection is fixed by welding or threaded connection, the nozzle branch pipe 1-1 and the nozzle main pipe 1-2 are connected by welding; for the dyed object 11 with...

Embodiment 3

[0028] Embodiment three, the embodiment of supercritical fluid jet dyeing, such as Figure 6 shown.

[0029] Utilize the technological process that the present invention carries out supercritical fluid spray dyeing as:

[0030] Firstly, the supercritical fluid medium in the supercritical fluid medium storage subsystem 12 flows through the supercritical fluid generating subsystem 13 to generate supercritical fluid meeting the conditions of the jet dyeing process.

[0031] Second, the dyed object 11 bypasses the squirrel-cage dyeing cylinder 2 under the guidance of the cloth guide roller 8, runs along the direction of the process requirements with the rotation of the rolling dyeing roller 2, and passes through the cleaning injector 15, dyeing machine, etc. Injector 16 and rinse injector 17 .

[0032] Third, after the pure supercritical fluid in the supercritical fluid generation subsystem 13 flows through the nozzle main pipe 1-2 and the nozzle branch pipe 1-1 of the cleaning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com