Method and device for static dyeing by adopting supercritical fluid

A supercritical fluid, static technology, applied in solvent dyeing, textile and papermaking, textile material processing and other directions, can solve the problems of difficult dye cleaning, high cost, difficult dyeing quality monitoring, etc., to achieve simple system equipment and equipment investment. And the effect of reducing energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

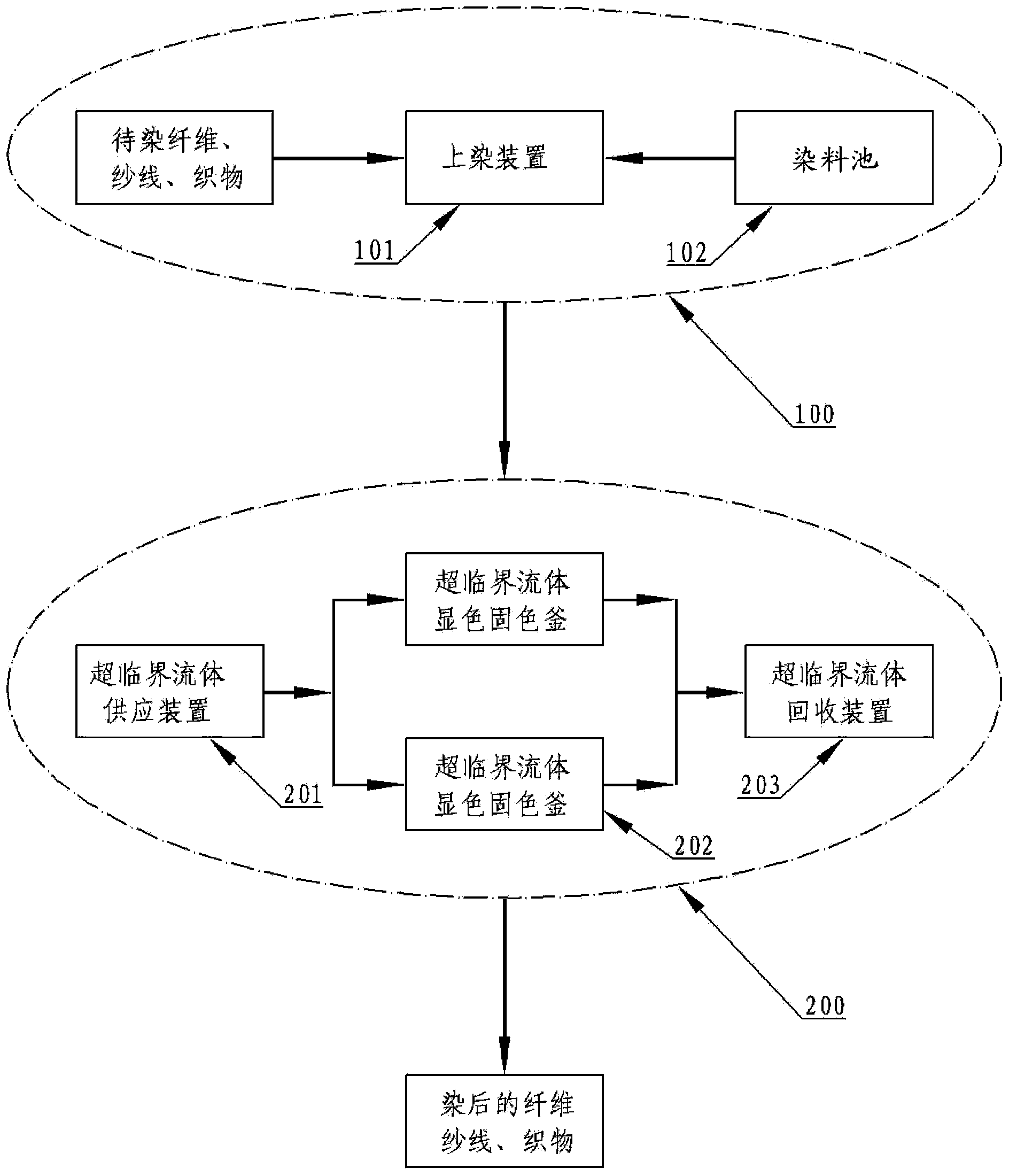

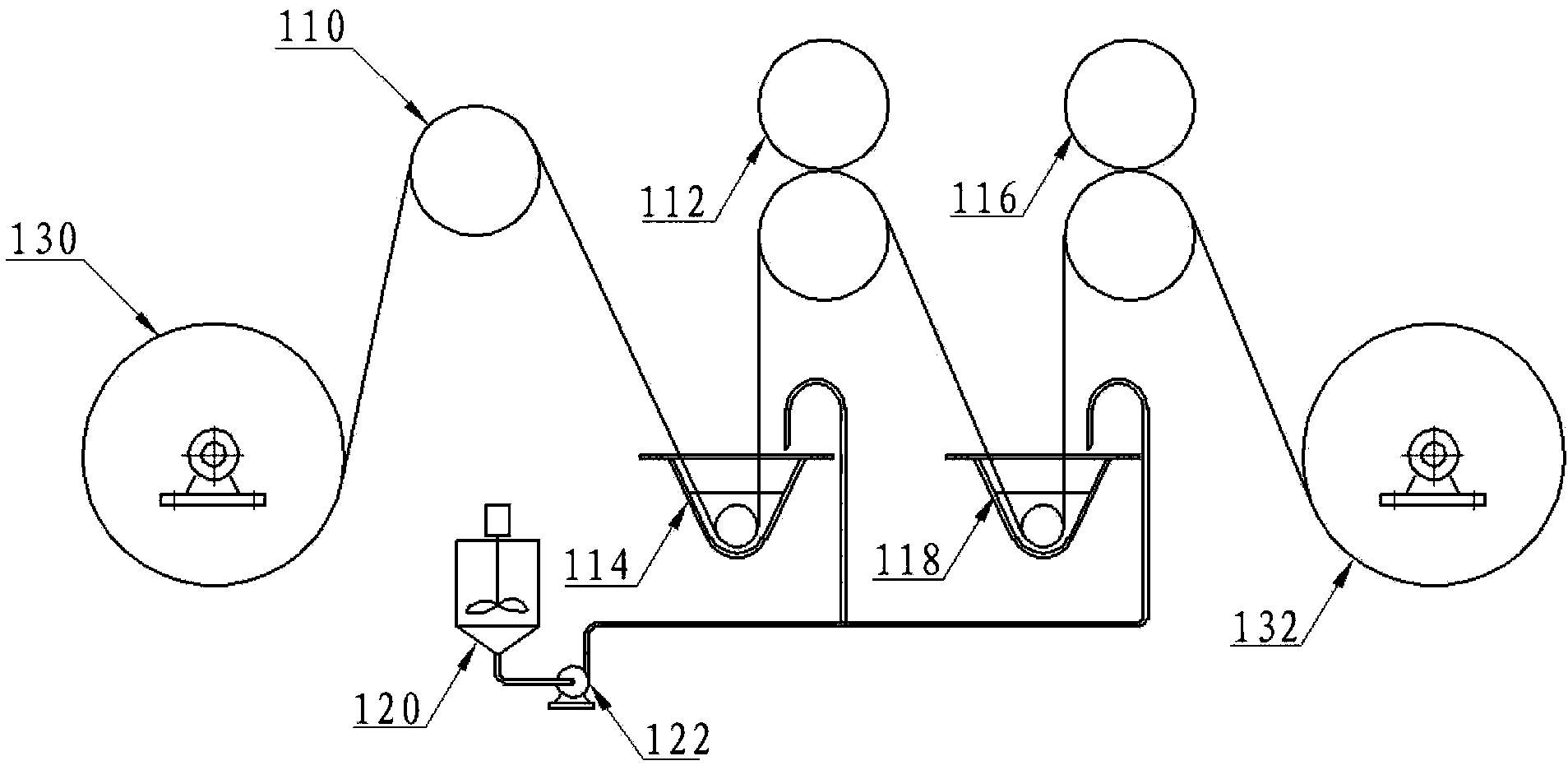

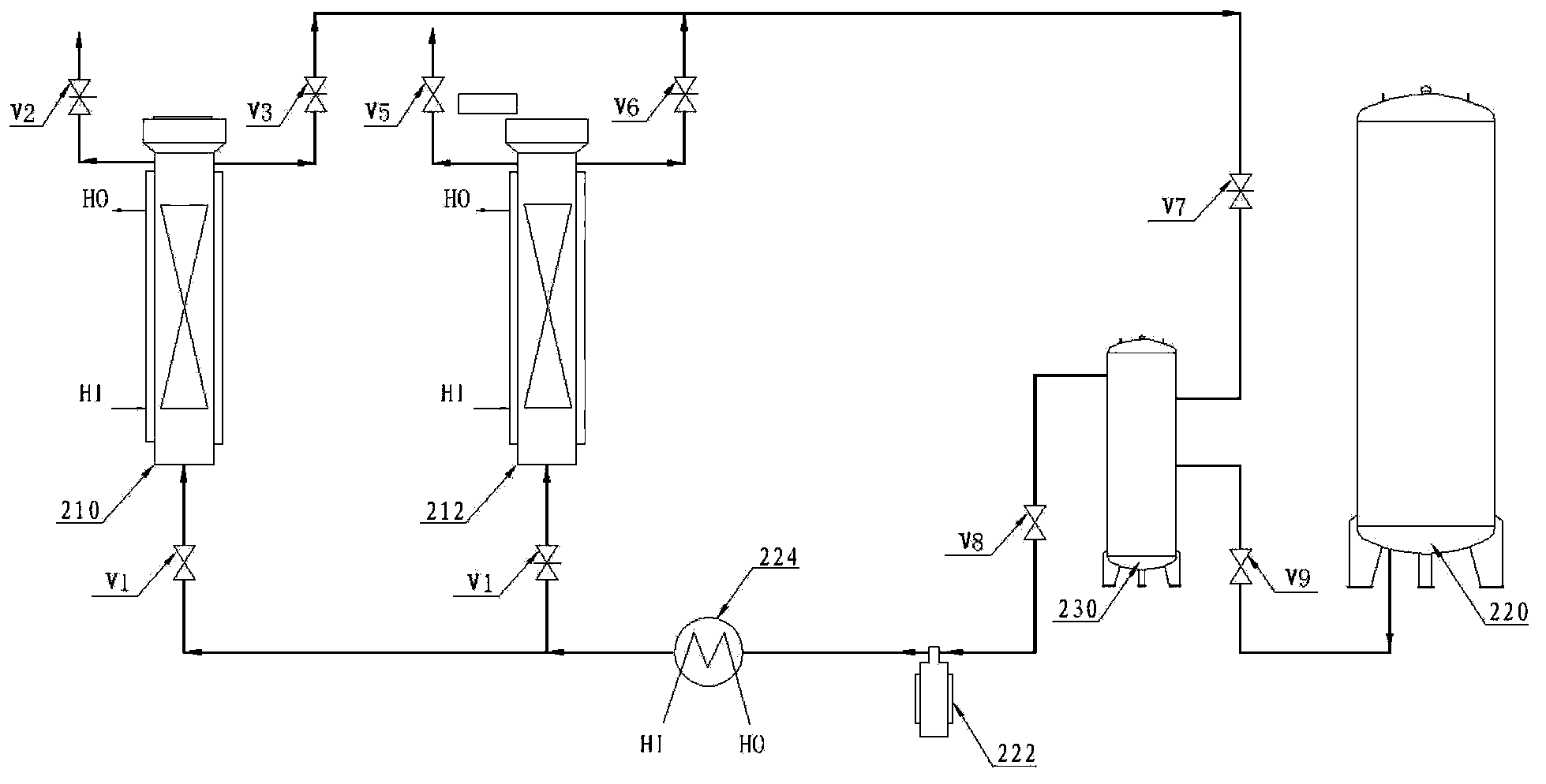

[0034] The invention provides a static dyeing device using supercritical fluid, as attached figure 1 , 2 The structure schematic diagram of an embodiment of the device using supercritical fluid static dyeing shown in and 3 includes a dyeing system 100 and a supercritical fluid static color development and color fixing system 200, and the dyeing system 100 includes a dyeing system 100 Device 101 and the dye pool 102 connected with the dyeing device 101; the supercritical fluid static color development and color fixing system 200 includes a supercritical fluid supply device 201, one or more units connected with the supercritical fluid supply device 201 More than one supercritical fluid color-fixing tank 202 connected in parallel, and a supercr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com