Fabrication process of anti-wrinkling and damp-proof decoupage handicraft article

A production process and handicraft technology, applied in decorative arts, special decorative structures, etc., can solve the problems of poor anti-wrinkle ability, limited layout environment, easy curling and falling off, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] Such as Figure 1-3 As shown, a kind of wrinkle-resistant and moisture-proof paper-cut decorative handicraft manufacturing process disclosed by the present invention, its process steps are as follows:

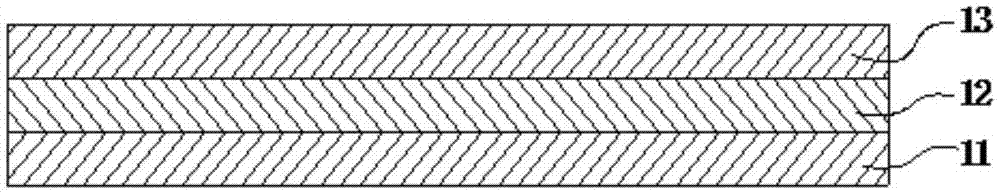

[0019] 1) Making metal-plated plastic film 11: Take PET material and coat it with EVA, use a vacuum furnace to atomize the dye anodized aluminum in a vacuum environment above 1000°C, and attach it to the surface of the PET material coated with EVA to form a metal-plated plastic film. Metal plastic film 11;

[0020] 2) Making the composite substrate layer 1: take the metallized plastic film 11 of step 1), apply a heat-sensitive resin on the metallized plastic film 11 to form an adhesive layer 12, and then corona treat the adhesive layer 12, Composite transparent adhesive film 13 to make composite substrate layer 1;

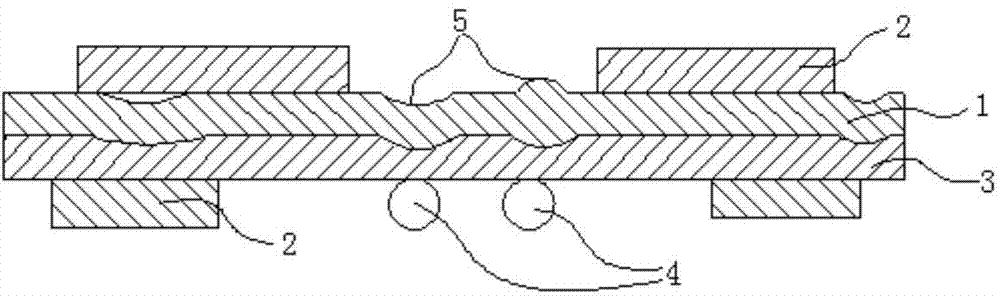

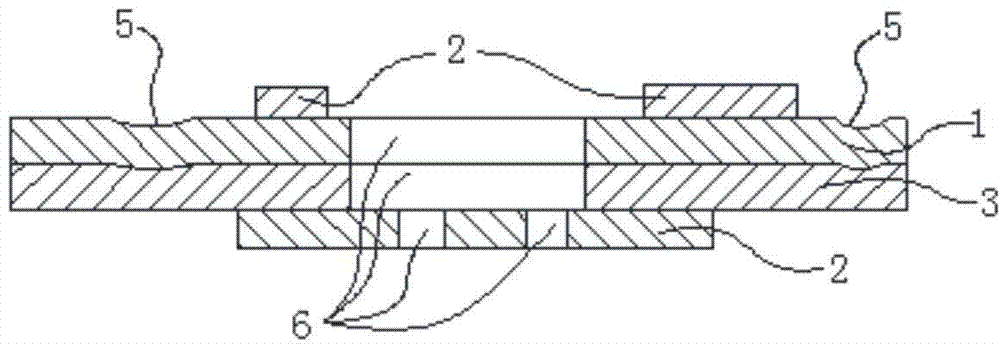

[0021] 3) Squeeze the reinforcing rib 5: Extrude and / or cut the surface of the composite substrate layer 1 prepared in step 2) with a copper plate at a tem...

specific Embodiment 2

[0023] Such as Figure 1-3 As shown, a kind of wrinkle-resistant and moisture-proof paper-cut decorative handicraft manufacturing process disclosed by the present invention, its process steps are as follows:

[0024] 1) Production of metal-plated plastic film 11: Coat PET material with EVA, use a vacuum furnace, and in a vacuum environment above 1000°C, atomize the dye electrochemically and attach it to the surface of the PET material coated with EVA to form a plated film. Metal plastic film 11;

[0025] 2) Making composite substrate layer 1: take the metallized plastic film 11 in step 1), apply photosensitive resin on the metallized plastic film 11 to form an adhesive layer 12, and then pass corona treatment on the adhesive layer 12 to compound Upper transparent adhesive film 13, make composite substrate layer 1;

[0026] 3) Squeeze the ribs 5: Extrude and / or cut the surface of the composite substrate layer 1 prepared in step 2) with a copper plate at a temperature of 120°C...

specific Embodiment 3

[0028] Such as Figure 1-3 As shown, a kind of wrinkle-resistant and moisture-proof paper-cut decorative handicraft manufacturing process disclosed by the present invention, its process steps are as follows:

[0029] 1) Production of metal-plated plastic film 11: Take PET material and coat it with EVA, use a vacuum furnace to atomize the dye anodized aluminum in a vacuum environment above 1000°C, and attach it to the surface of the PET material coated with EVA to form a metal-plated plastic film. Metal plastic film 11;

[0030] 2) Making the composite substrate layer 1: take the metallized plastic film 11 of step 1), apply a heat-sensitive resin on the metallized plastic film 11 to form an adhesive layer 12, and then corona treat the adhesive layer 12, Composite transparent adhesive film 13 to make composite substrate layer 1;

[0031] 3) Squeeze the reinforcing ribs 5: Extrude and / or cut the surface of the composite substrate layer 1 prepared in step 2) with a copper plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com