Sound-insulation noise-reduction system of roll-packing machine

A roll-up and noise-reduction technology, which is applied in the direction of sound-proof doors/windows, sound-emitting devices, instruments, etc., can solve the problems of insignificant treatment effect, insignificant noise reduction effect, poor sound absorption and noise reduction, etc., and achieves significant noise reduction effect, Wide applicability, effect of reducing indoor noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

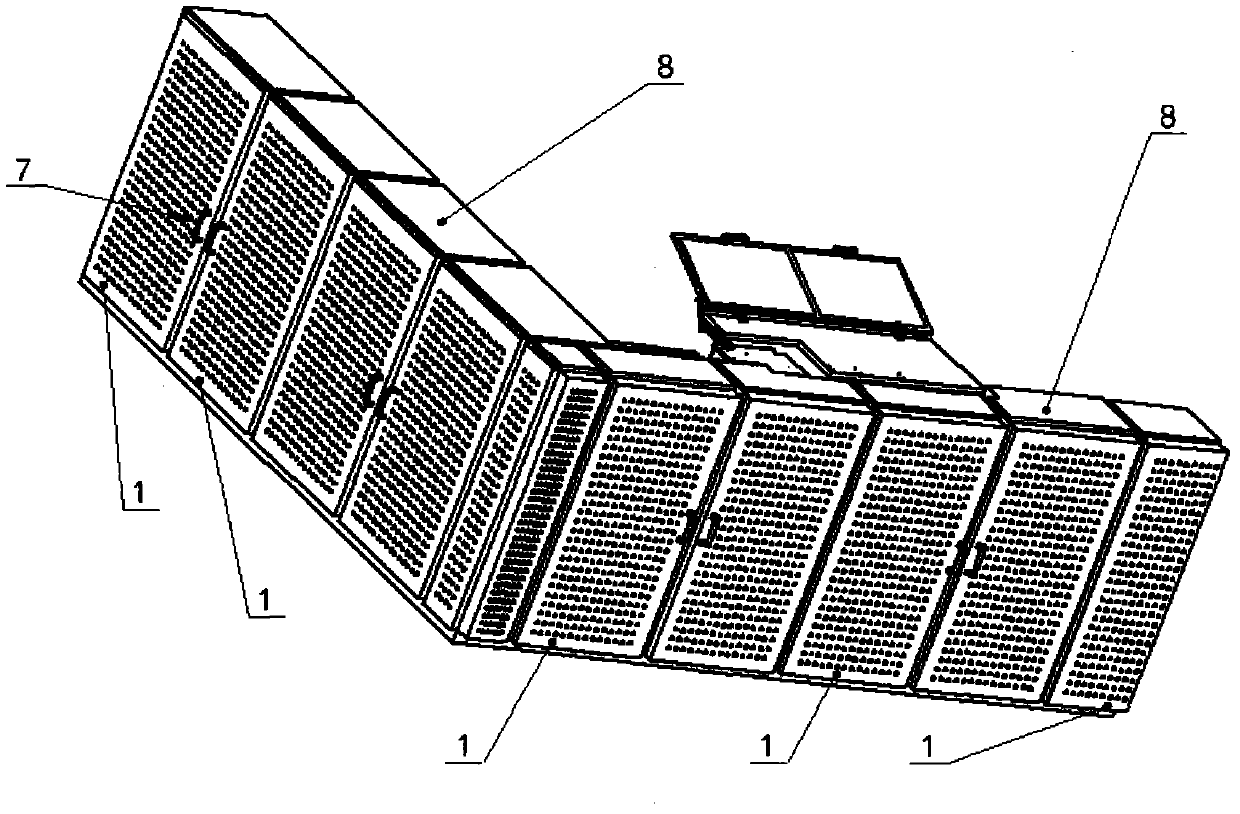

[0024] The patent of the present invention will be described in detail below in conjunction with the accompanying drawings.

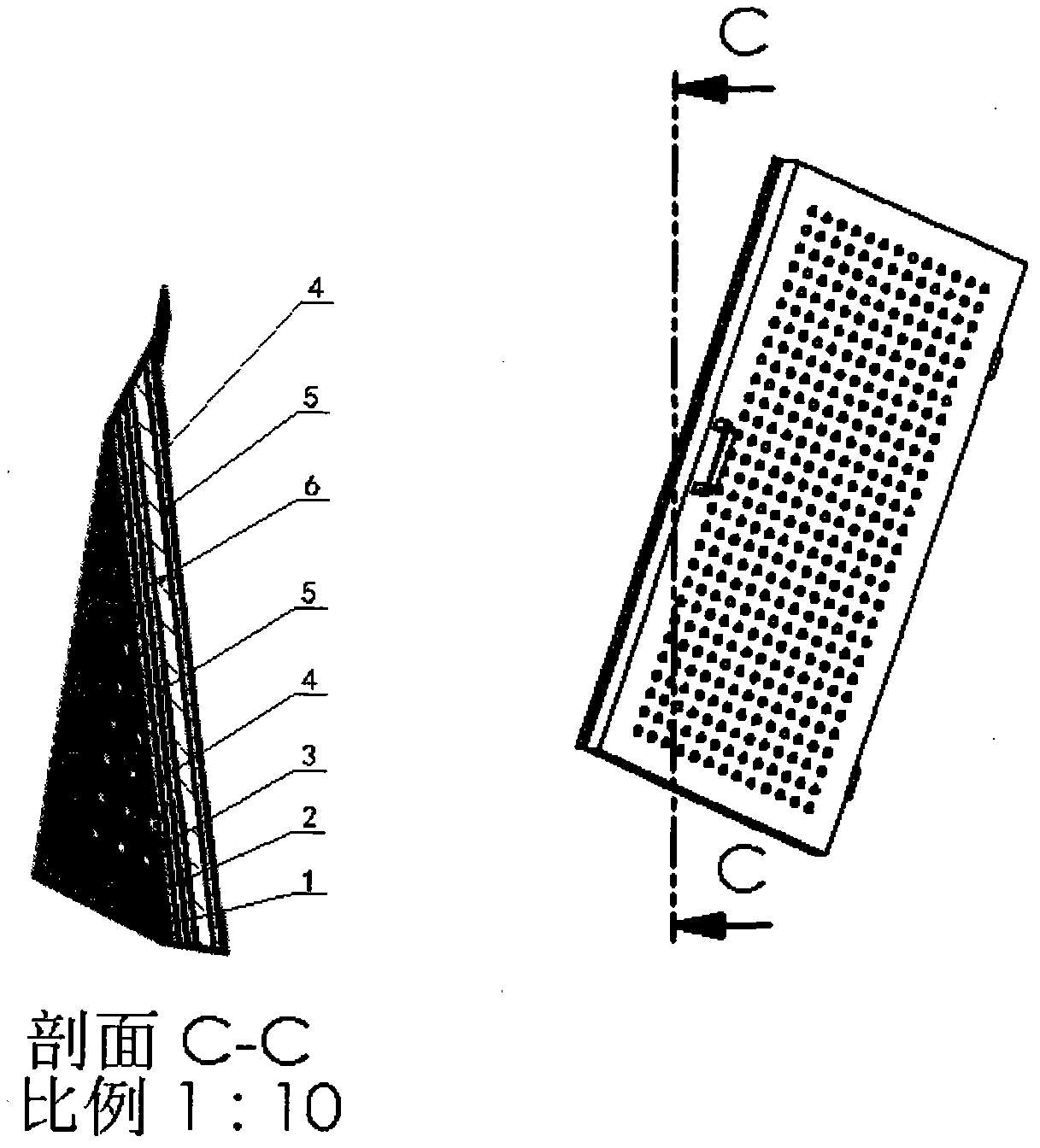

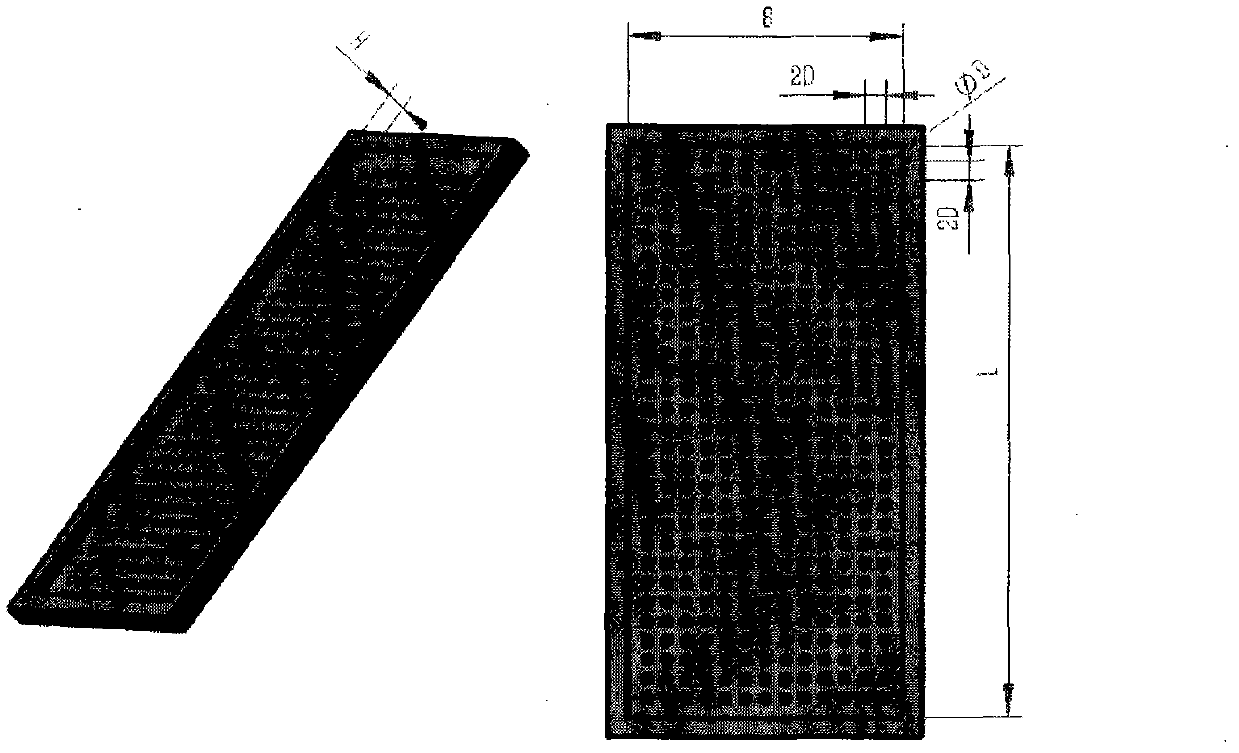

[0025] see figure 1 , using stainless steel sheet design casing 1, such as figure 2 , the outer size of the casing 1 is consistent with the size of the protective door of the cigarette maker, the length and width of the inner groove are L and B respectively, and the depth is H, and the H value is slightly larger than the rubber coating 2, the foam sound-absorbing metal plate 3, and the fiber sound-absorbing The sum of the thicknesses of the plate 4, the tempered vacuum glass 5, and the sound-absorbing cloth cover 6.

[0026] Such as figure 2 , the diameter is machined on the outer surface of casing 1 The through-holes, the center-to-center distance of adjacent holes is 2D=30mm. Spray the noise-reducing rubber coating 2 on the inner side of the casing 1, and apply 2-3 layers. After the first layer is dry, apply the second layer. The thickness of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com