Durable lavender aroma type long stapled cotton/fine denier nylon knitted fabric product

A technology of lavender and long-staple cotton, which is applied in knitting, weft knitting, essential oils/fragrances, etc. It can solve the problems of filament products that need to be improved, and achieve significant anti-wrinkle ability, long-lasting fragrance and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

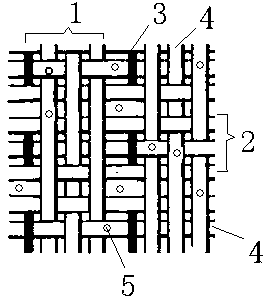

[0032] Such as figure 1 As shown, the durable lavender-flavored long-staple cotton / fine-denier nylon knitted fabric product, its warp yarns include long-staple cotton 3 and fine-denier nylon filament 4, and each long-staple cotton 3 is formed by every three fine-denier nylon filaments 4 One warp-knit unit 1; the weft yarn is fine-denier nylon yarn 4, and every three fine-denier nylon yarns 4 form a weft-knit unit 2; the spacing between adjacent warp-knit unit 1 is 0.3mm, and the spacing between adjacent weft-knit unit 2 is 0.25 mm; the warp and / or weft direction of the knitted fabric product is provided with lavender essential oil microcapsules 5 . The total number of warp and weft yarns per square inch of knitted fabrics is 300. The warp yarn is a combination of 16 counts of long-staple cotton 3 and 150D fine-denier nylon yarn 4. The distance between the long-staple cotton 3 and the fine-denier nylon filament 4 in each tissue unit 1 is 0.1 mm, and the distance between adjac...

Embodiment 2

[0040] Such as figure 1As shown, the durable scented long-staple cotton / fine-denier nylon knitted fabric product, its warp yarns include long-staple cotton 3 and fine-denier nylon filament 4, and every 1 long-staple cotton 3 and every 3 fine-denier nylon filaments 4 form a Warp weave unit 1; the weft yarn is fine-denier nylon yarn 4, and every three fine-denier nylon yarns 4 form a weft weave unit 2; the distance between adjacent warp weave units 1 is 0.5 mm, and the distance between adjacent weft weave units 2 is 0.4 mm; the warp and / or weft direction of the knitted fabric product is provided with lavender essential oil microcapsules 5 . The total number of warp and weft yarns per square inch of knitted fabrics is 350. The warp yarn is a combination of 16 counts of long-staple cotton 3 and 150D fine-denier nylon yarn 4. The distance between the long-staple cotton 3 and the fine-denier nylon filament 4 in each organized unit 1 is 0.2 mm, and the distance between adjacent fin...

Embodiment 3

[0048] Such as figure 1 As shown, the durable scented long-staple cotton / fine-denier nylon knitted fabric product, its warp yarns include long-staple cotton 3 and fine-denier nylon filament 4, and every 1 long-staple cotton 3 and every 3 fine-denier nylon filaments 4 form a Warp weave unit 1; the weft yarn is fine-denier nylon yarn 4, and every three fine-denier nylon yarns 4 form a weft weave unit 2; the distance between adjacent warp weave units 1 is 0.4 mm, and the distance between adjacent weft weave units 2 is 0.3 mm; the warp and / or weft direction of the knitted fabric product is provided with lavender essential oil microcapsules 5 . The total number of warp and weft yarns per square inch of knitted fabrics is 320. The warp yarn is a combination of 16 counts of long-staple cotton 3 and 150D fine-denier nylon yarn 4. The distance between the long-staple cotton 3 and the fine-denier nylon filament 4 in each tissue unit 1 is 0.15 mm, and the distance between adjacent fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com