Honeycomb paper core innovation structure and core paper gluing technique

A technology of honeycomb paper core and process method is applied in the fields of innovative honeycomb paper core structure and core paper bonding process, reinforced honeycomb sandwich paper core structure and core paper bonding process, which can solve the limitation of honeycomb paperboard compressive strength, high The problems such as the difficulty of drawing the quantitative core paper and the complicated transformation of the production line can achieve the effect of low production cost, reduced core paper forming difficulty, and great strength improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

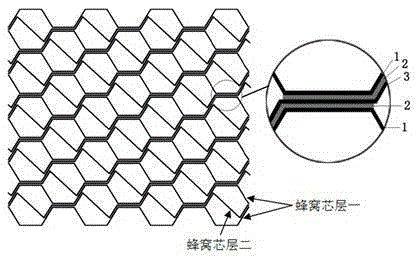

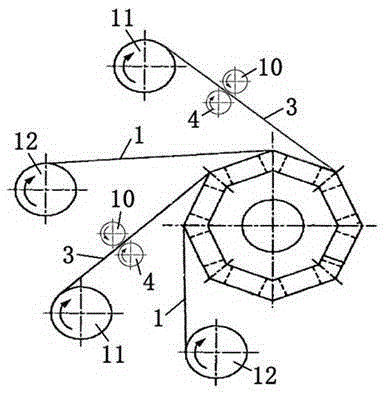

[0024] Such as figure 1 As shown, it can be seen from the cross-section of the designed new honeycomb sandwich panel core structure that the core structure is composed of honeycomb core layer 1 (original honeycomb core layer 1) and honeycomb core layer 3 (new honeycomb core layer 2) , the shape of the honeycomb core layer 3 in the honeycomb cell is determined by the bonding size of the honeycomb core layer 1 and the honeycomb core layer 3 . The bonding process of the honeycomb paper core of this structure is as follows: figure 2 and Figure 5 shown.

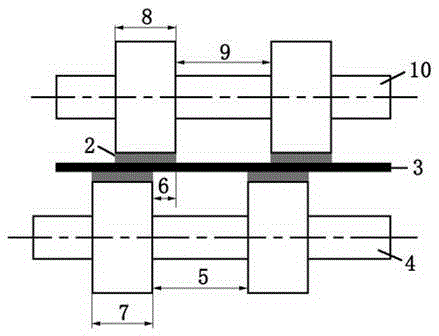

[0025] figure 2 The honeycomb core layer Bafang roller bonding process shown: Fix two groups of honeycomb core paper 1 roll paper 12 and honeycomb core paper 3 roll paper 11 on four paper frames at intervals, honeycomb core paper 1 and honeycomb core paper 3 It is one group, two groups in total, in each g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com