Leveling device for scraper conveyor

The technology of scraper conveyor and leveling device is applied in the direction of conveyor objects, transportation and packaging, underground transportation, etc., and can solve the problems of coal seam sheet helping people, threatening the personal safety of coal mine production safety operators, and hurting people, etc. Achieve the effect of avoiding coal wall bias, reducing coal wall bias, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

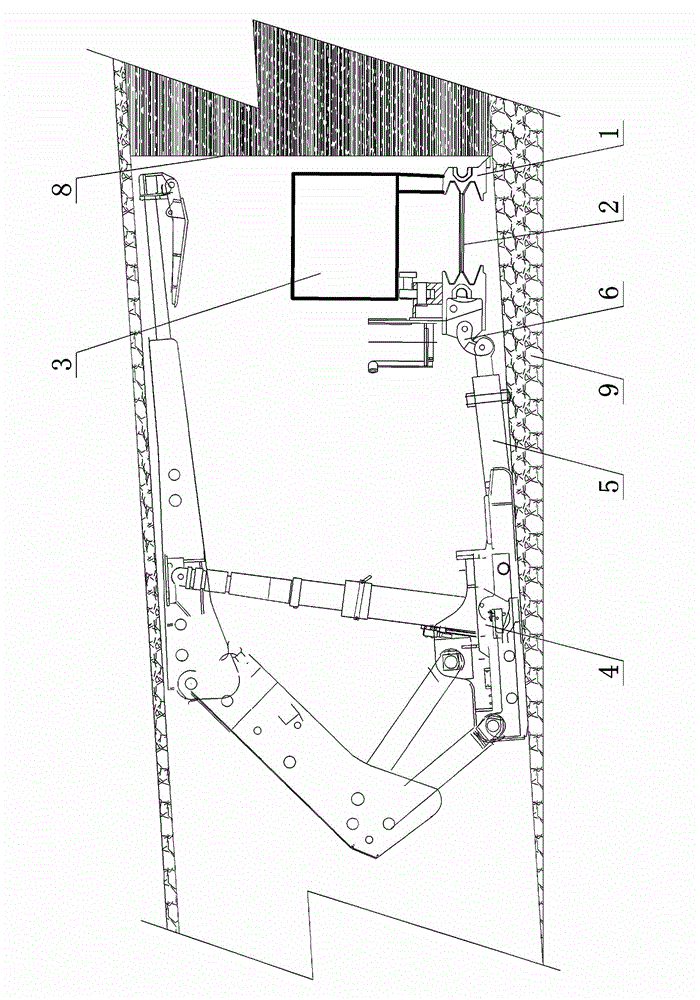

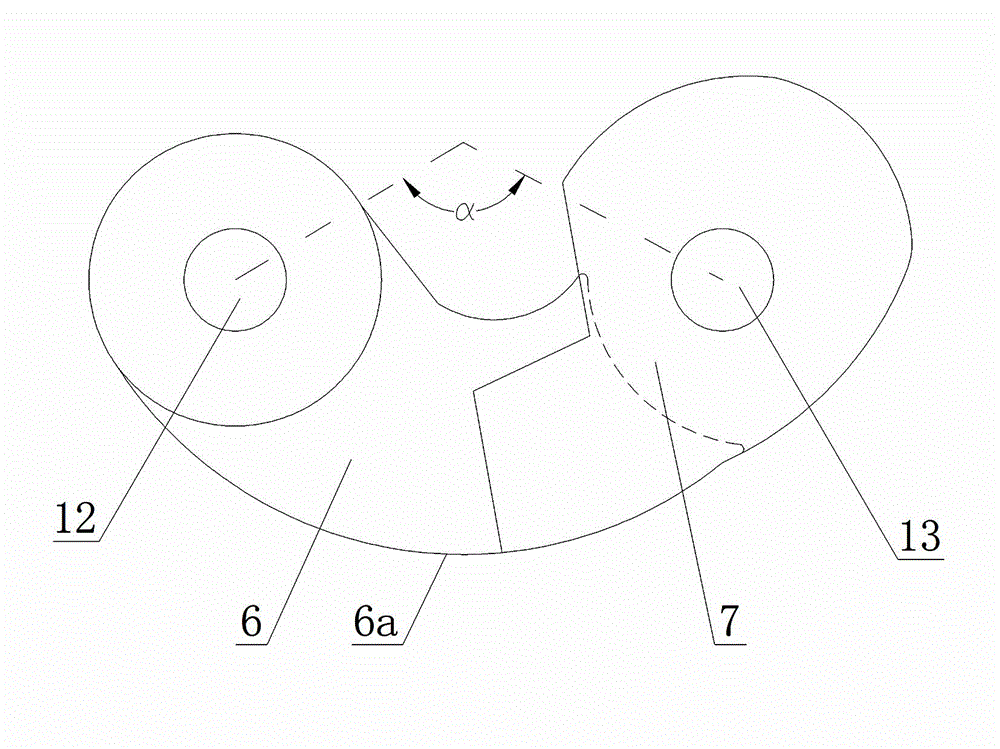

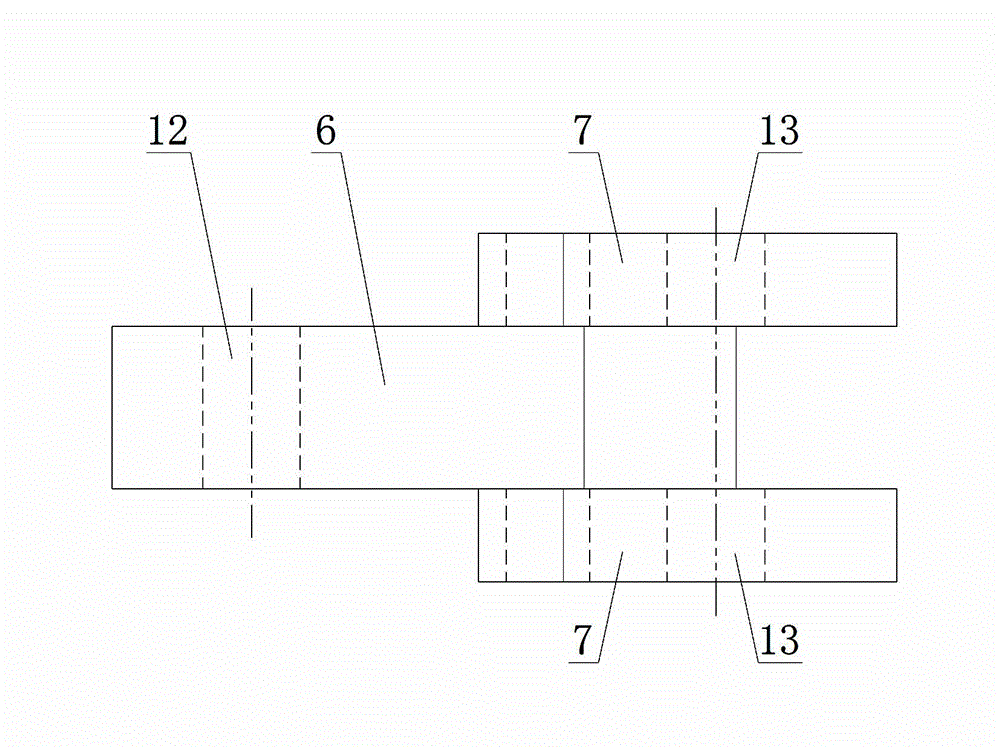

[0020] see Figure 1 to Figure 5 , an embodiment of a leveling device for a scraper conveyor, the device includes a scraper conveyor 1, a hydraulic support 4, the scraper conveyor 1 is provided with a slider 2 on the working surface, and the hydraulic support 4 is provided with a push rod 5. The shearer 3 is located on the scraper conveyor 1 and is used for mining coal mines. The working face slider 2 and the push rod 5 are hinged through the adjusting arm 6, and the adjusting arm 6 is in a curved shape, and one end thereof is provided with a hinge hole 12 to be hinged with the working surface slider 2 through a pin 10, so that the working surface slider 2 It can rotate up and down around one end of the adjusting arm 6 to adjust the levelness of the working face sled 2 on the roadway floor 9 of the mining working face; on both sides of the other end of the adjusting arm 6 are symmetrical arms 7 extending along the curved convex arc edge 6a, In this embodiment, the two symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com