Preparation method of porous Al2O3 ceramic

A ceramic and mixed liquid technology, applied in the field of material science, can solve the problems of many processes, poor pore distribution uniformity, large energy consumption, etc., and achieves the effect of simple operation process, easy promotion, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: 1) First, get 8g of sintered platy corundum powder and 5ml of water glass solution with a mass concentration of 50% and mix them uniformly to obtain a mixed solution; 2) Secondly, place the mixed solution in a mold, and place the mixed solution Put the mold into a vacuum freeze dryer and freeze at -30°C for 24 hours to freeze the mixture completely, then dry the frozen mixture thoroughly under vacuum, and then demould the sample, the porous Al 2 o 3 block; 3) Then, the demolded porous Al 2 o 3 The block was placed in a high-temperature box-type electric furnace from room temperature to 1600 °C at a heating rate of 5 °C / min, and kept for 2 hours for sintering; 4) Finally, porous Al was obtained by naturally cooling to room temperature with the furnace. 2 o 3 ceramics.

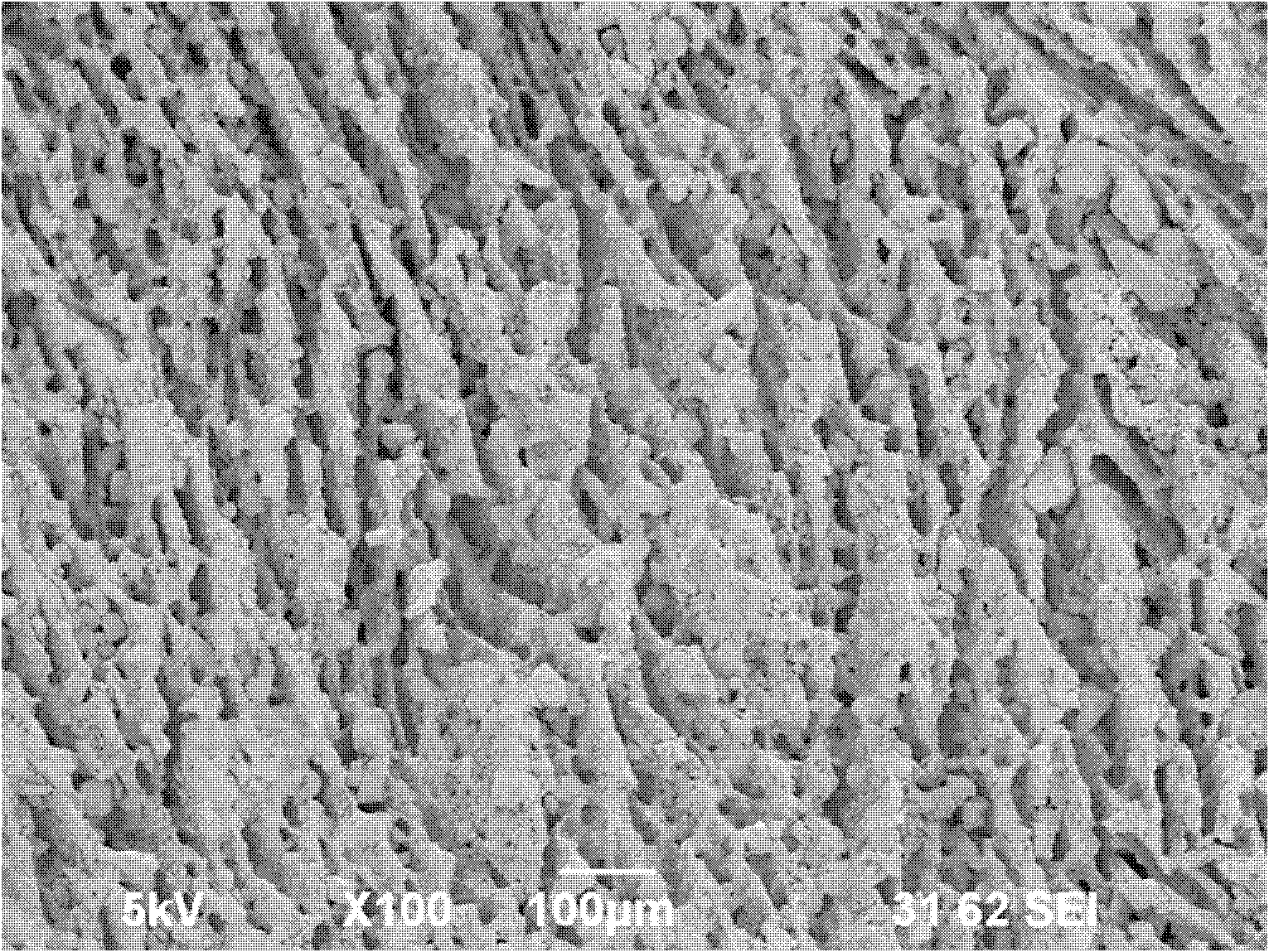

[0012] Scan test photos see figure 1 .

[0013] Depend on figure 1 It can be seen that the porous Al prepared in this example 2 o 3 The ceramics have obtained the pores of the lamel...

Embodiment 2

[0014] Embodiment 2: 1) First, get 8g of sintered platy corundum powder and 15ml of mass concentration of 30% water glass solution to mix uniformly to obtain a mixed solution; 2) Secondly, place the mixed solution in a mold, and fill the mixed solution Put the mold into a vacuum freeze dryer and freeze at -30°C for 24 hours to freeze the mixture completely, then dry the frozen mixture thoroughly under vacuum, and then demould the sample, the porous Al 2 o 3 block; 3) Then, the demolded porous Al 2 o 3 The block was placed in a high-temperature box-type electric furnace from room temperature to 1600 °C at a heating rate of 5 °C / min, and kept for 2 hours for sintering; 4) Finally, porous Al was obtained by naturally cooling to room temperature with the furnace. 2 o 3 ceramics.

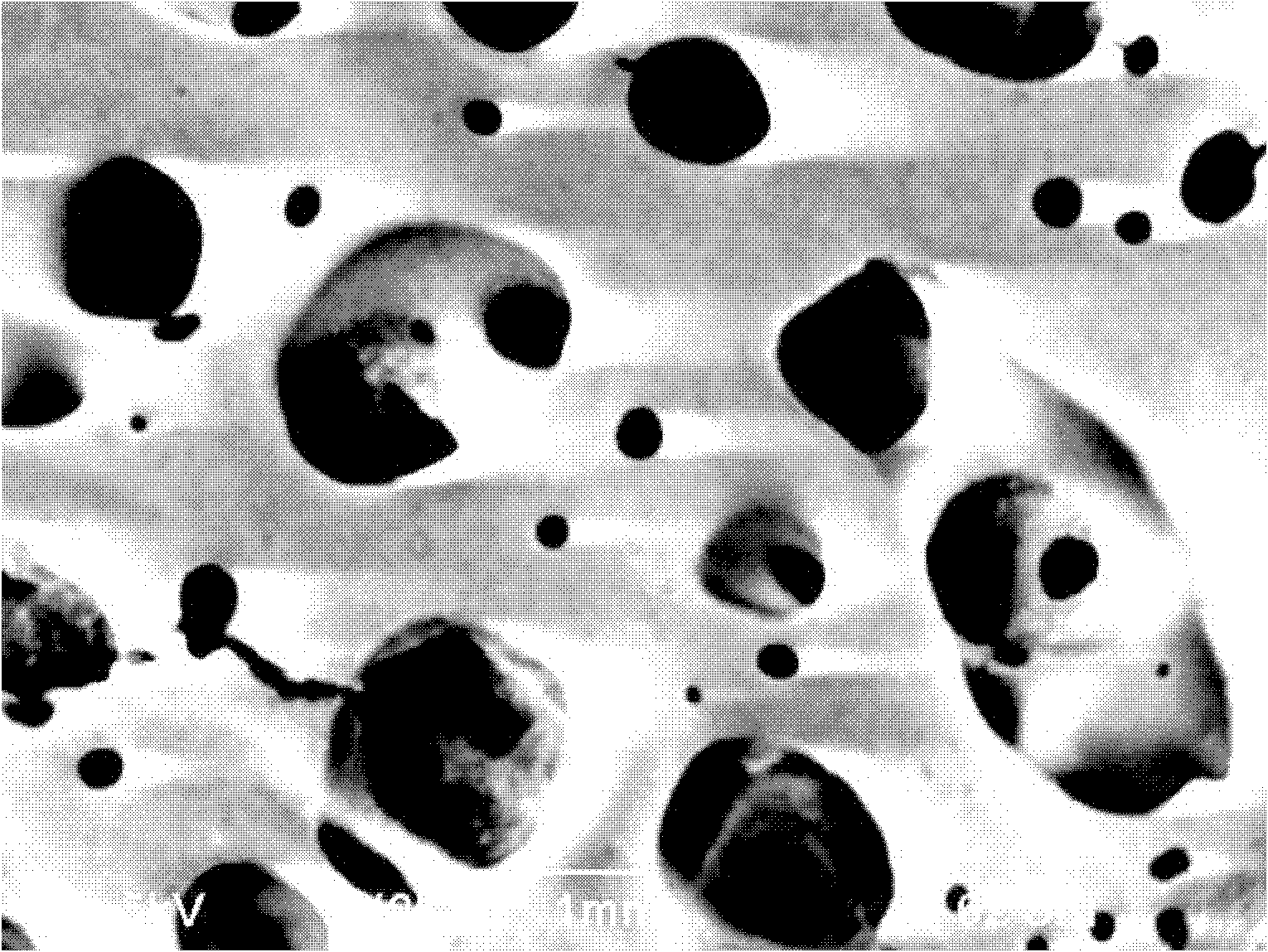

[0015] Scan test photos see figure 2 .

[0016] Depend on figure 2 It can be seen that the porous Al prepared in this example 2 o 3 Ceramics have circular pores, smaller micropores exist on th...

Embodiment 3

[0017] Embodiment 3: 1) First, get 8g of sintered platy corundum powder and 2ml of water glass solution with a mass concentration of 50% to mix uniformly to obtain a mixed solution; 2) Secondly, place the mixed solution in a mold, and fill the mixed solution Put the mold into a vacuum freeze dryer and freeze at -40°C for 60 hours to freeze the mixture completely, then dry the frozen mixture thoroughly under vacuum, and then demould the sample, the porous Al 2 o 3 block; 3) Then, the demolded porous Al 2 o 3 The block was placed in a high-temperature box-type electric furnace from room temperature to 1550 °C at a heating rate of 5 °C / min, and kept for 2 hours for sintering; 4) Finally, the porous Al was obtained by naturally cooling to room temperature with the furnace. 2 o 3 ceramics.

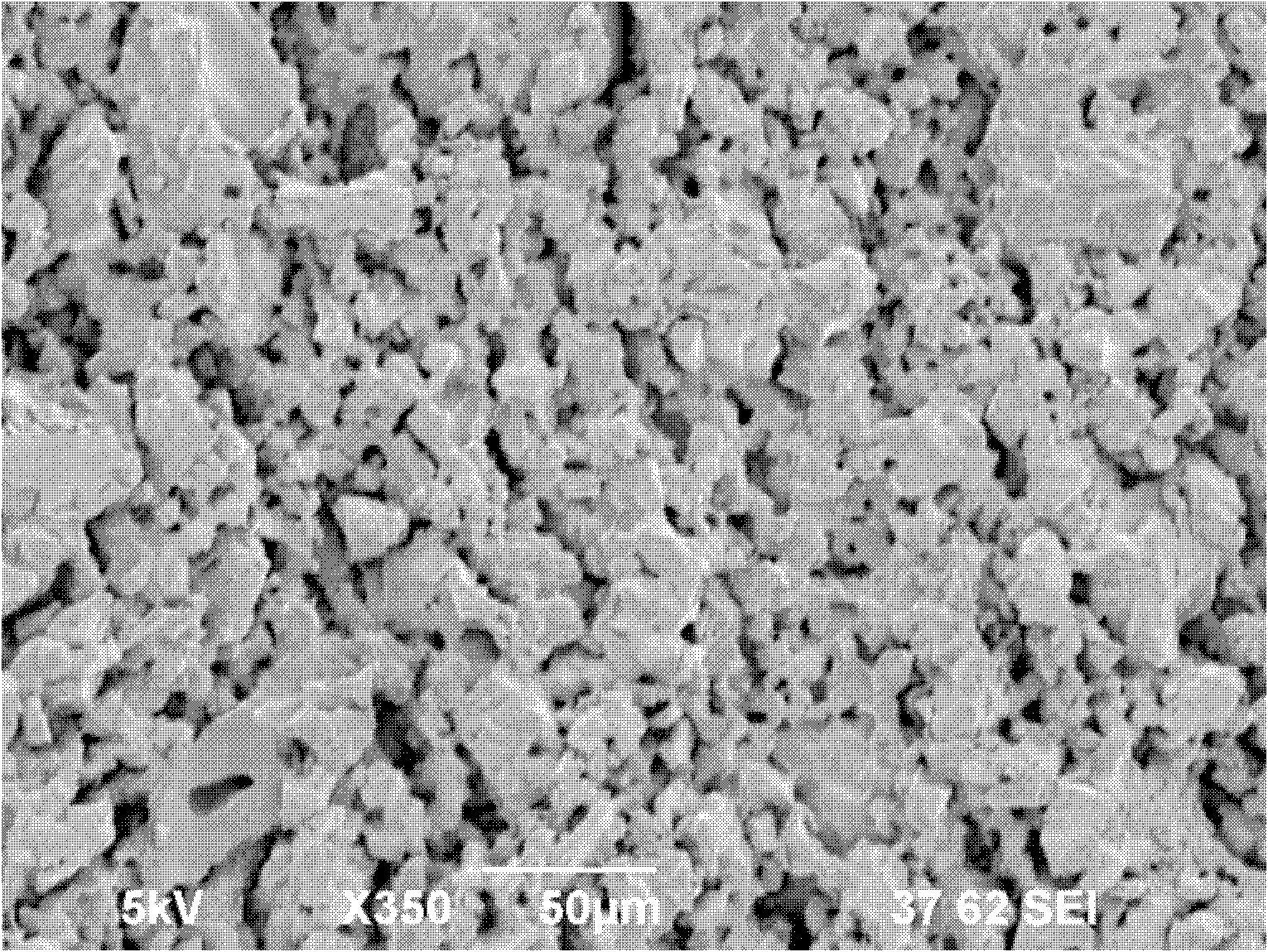

[0018] Scan test photos see image 3 .

[0019] Depend on image 3 It can be seen that the porous Al prepared in this example 2 o 3 After the content of water glass solution is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com