Porous microcryogel cell three-dimensional culture carrier, and preparation method and preparation system thereof

A three-dimensional culture and preparation system technology, applied in the field of porous micro-ice gel cell three-dimensional culture carrier and its preparation, can solve the problems of cell phenotype change, inability to simulate the three-dimensional growth environment of cells, and the limited space of two-dimensional culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

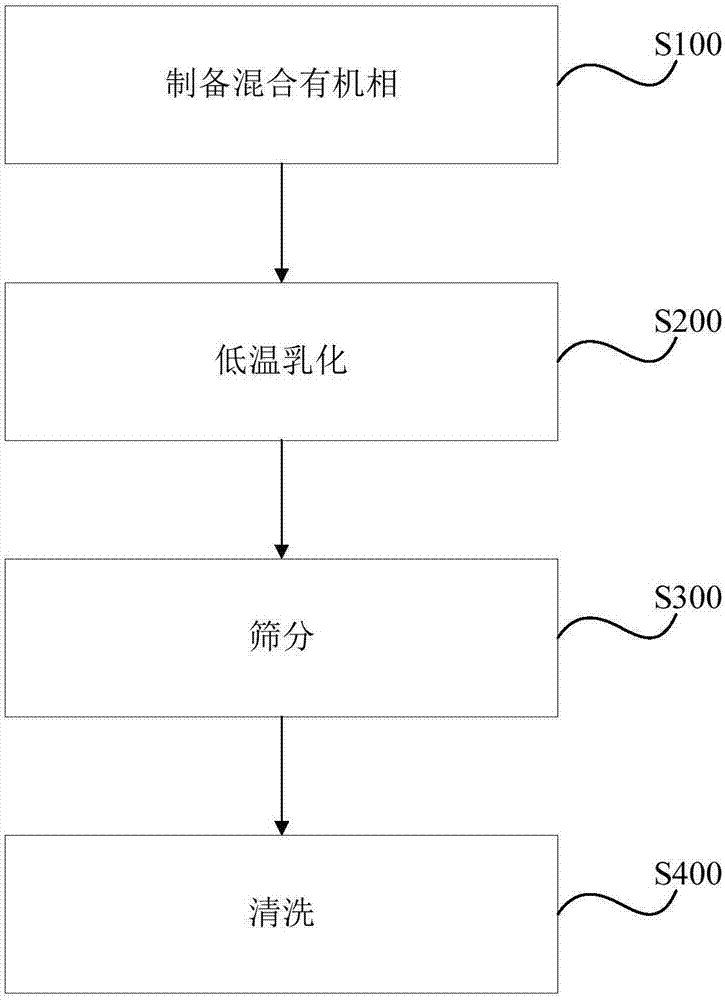

[0044] According to one aspect of the present invention, the present invention proposes a method for preparing a porous microcryogel cell three-dimensional culture carrier. The method for preparing a porous microcryogel cell three-dimensional culture carrier according to an embodiment of the present invention includes: preparing a mixed organic phase; Aqueous phase solution is added to the phase and emulsified by stirring method, ultrasonic method or microchannel method to obtain a uniform water-in-oil emulsion system; the water-in-oil emulsion system is filtered to leave the carrier material to be cleaned; the carrier material The material is washed to obtain a three-dimensional culture carrier of porous micro-ice jelly cells, wherein the emulsification is carried out at a temperature not higher than zero degrees Celsius.

[0045] Therefore, by adopting this method, the homogeneous mass production of the porous microcryogel cell three-dimensional culture carrier can be realize...

Embodiment 1

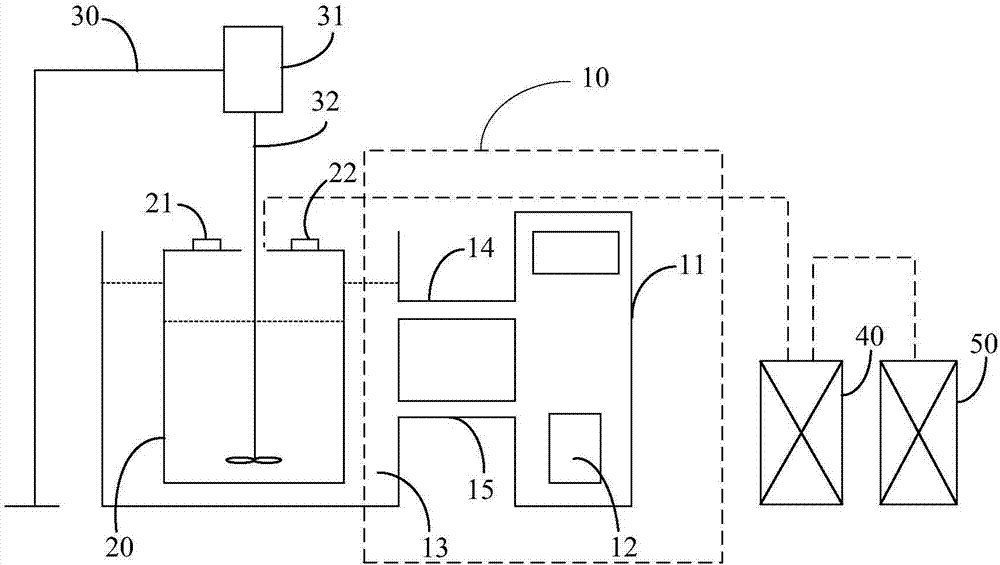

[0098] Prepare and mix the organic phase and place it in the reaction kettle, add the aqueous phase solution into the organic phase under the stirring action of the stirring paddle, emulsify through stirring to form uniformly dispersed emulsion droplets, and obtain porous micro-ice gel after filtering and washing Three-dimensional cell culture carrier. Wherein, during the emulsification process, the low-temperature circulation device is used to provide circulating low-temperature ethanol, and the temperature in the entire reactor is controlled to be maintained at -20 degrees Celsius; and the rotation speed of the stirring blade is controlled to be 1500rmp / min.

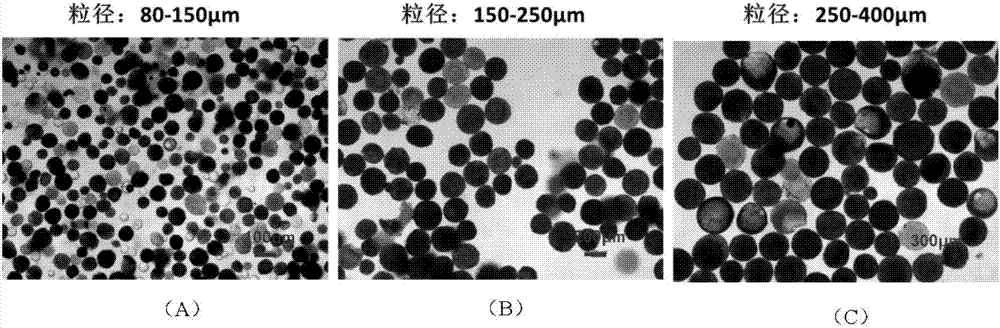

[0099] The microscopic image of the porous microcryogel cell three-dimensional culture carrier prepared by this method and re-immersed in aqueous solution after the final freeze-drying is as follows: image 3 As shown in (A), it shows that a uniform spherical microcryogel carrier with a particle size range of 80-150 μm...

Embodiment 2

[0101] Prepare and mix the organic phase and put it in the reaction kettle, add the aqueous phase solution into the organic phase under the stirring action of the stirring paddle, emulsify through stirring to form uniformly dispersed emulsion droplets, filter and wash to obtain porous micro-cryogel Three-dimensional cell culture carrier. Wherein, in the emulsification process, the low-temperature circulation device is used to provide circulating low-temperature ethanol, and the temperature in the entire reactor is controlled to be maintained at -30 degrees Celsius; and the rotation speed of the stirring blade is controlled to be 1000rmp / min.

[0102] The microscope images of the microcryogel cell culture carrier prepared by this method re-immersed in aqueous solution after the final freeze-drying are as follows: image 3 As shown in (B), it shows that a uniform spherical microcryogel carrier with a particle size range of 150-250 μm can be prepared on a large scale; the SEM ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com