Preparation method of nano ferroferric oxide porous heavy metal adsorbing material

A technology of ferric tetroxide and adsorption materials, applied in chemical instruments and methods, preparation of microspheres, alkali metal compounds, etc., can solve the problems of high mechanical strength, low output, difficult change of material properties, etc., and achieves broad market prospects. Strong adsorption capacity and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

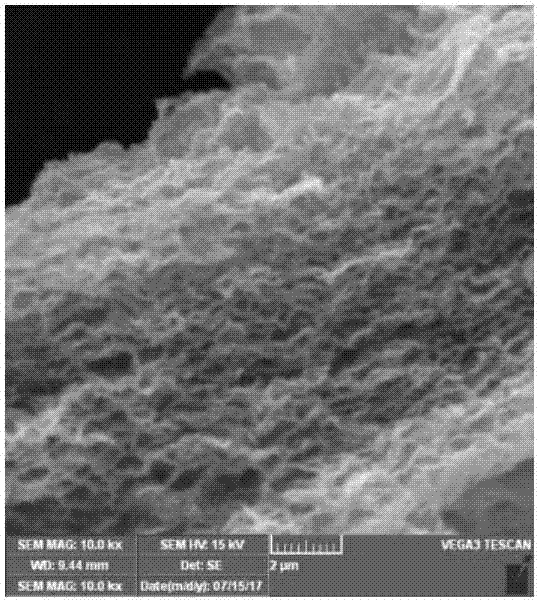

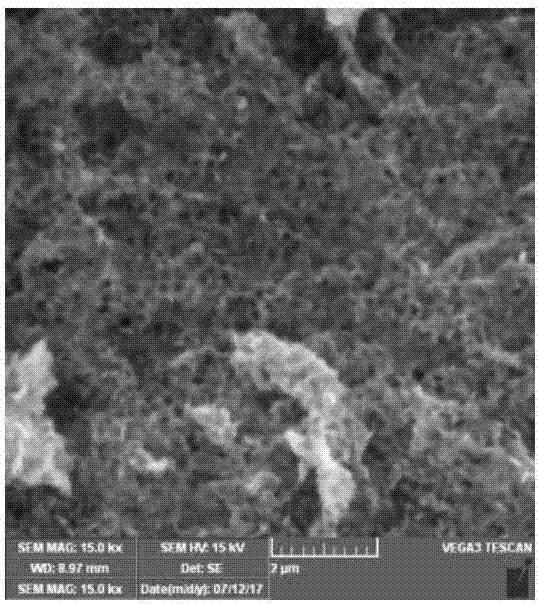

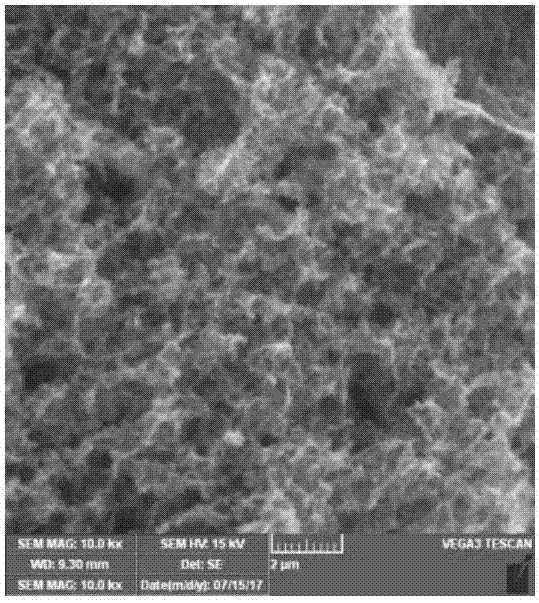

Image

Examples

Embodiment 1

[0040] A preparation method of a nanometer iron ferric oxide porous heavy metal adsorption material, comprising the following steps:

[0041] S1), prepare SiO according to the following steps 2 Microspheres;

[0042] S101), dissolving 0.01mol of citric acid in 10ml of ammonia water, stirring until the citric acid is completely dissolved, adding 0.01mol of ethyl orthosilicate, stirring evenly, and preparing solution A;

[0043] S102), take 0.5g of polyethylene glycol, dissolve in 50mL of a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1, stir until completely dissolved, and prepare solution B;

[0044] S103), mixing solution A and solution B, stirring evenly, adjusting the pH to 7-8 with ammonia water to prepare a precursor solution;

[0045] S104), the precursor solution is evaporated to a wet gel in a water bath at 80°C, and the wet gel is transferred to an oven to continue heating to 130-140°C to dry and foam to a dry gel;

[0046] S105),...

Embodiment 2

[0056] A preparation method of a nanometer iron ferric oxide porous heavy metal adsorption material, comprising the following steps:

[0057] S1), according to the following steps to prepare PS microspheres,

[0058] S101), 1.818g of polyvinylpyrrolidone (PVP), 95ml of absolute ethanol and 5ml of deionized water were added to the reaction kettle, stirred at a speed of 130r / min to form a homogeneous system, and blown with nitrogen gas Soak the air for 20 minutes;

[0059] S102), make the system heat up rapidly to 70°C, when the temperature is stable, add 20ml of styrene after removing the polymerization inhibitor, and 0.182g of initiator azobisisobutyronitrile (AIBN) to shake and dissolve, keep the stirring speed constant , reacted in nitrogen protection for 24h and cooled naturally to obtain a white emulsion;

[0060] S103), the above-mentioned white emulsion is subjected to centrifugal sedimentation at a speed of 5000r / min, the supernatant is removed, and absolute ethanol i...

Embodiment 3

[0069] A preparation method of a nanometer iron ferric oxide porous heavy metal adsorption material, comprising the following steps:

[0070] S1), prepare PMMA microspheres according to the following steps;

[0071] S101), the mixing of 1.5g dispersant polyvinylpyrrolidone (PVP), 10g monomer methyl methacrylate (MMA), 0.1g initiator azobisisobutyronitrile (AIBN) dissolved in 55g ethanol and 45g water In the solvent, the temperature was raised to 65-75°C for 6 hours, and the temperature was naturally lowered after the reaction;

[0072] S102), after cooling down, centrifuge the above-mentioned reaction product at a speed of 4000r / min, pour off the supernatant, add absolute ethanol to clean the lower layer of microspheres by ultrasonic dispersion, then centrifugal sedimentation, and then wash, repeat the operation 5 times , the centrifuged product was vacuum-dried at 60°C for 24 hours to obtain PMMA microspheres;

[0073] S2), take an appropriate amount of PMMA microsphere sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com