Hydraulic fluoride varnish material

A fluoride and hydraulic technology, applied in medical science, dentistry, dental preparations, etc., can solve the problems of poor fluoride release and poor hydrophilicity, and achieve the effects of low cost, good adhesion performance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Disperse 10g of sodium fluoride with an average particle size of 0.7μm and 3g of colloidal silicon dioxide in 50ml of 96% ethanol solution through an ultrasonic disperser, then add 88g of polymerized rosin, a film-forming material, and add maleated rosin, an adhesion promoter, after fully dissolving 70g, then add 3g of saccharin, 1g of watermelon essence, and continue to disperse for 3 hours until all the ingredients are completely dissolved, that is, the content of sodium fluoride is 5mg / ml, the content of film-forming material is 40%, the content of volatile solvent is 20%, and the adhesion promoter Fluoride coating material with a content of 30%. The fluoride can also be sodium monofluorophosphate, the solvent can be propanol and isopropanol, the film-forming material can be shellac, Copa resin, hydrogenated rosin, and the film-forming accelerator can be octadecyl phosphate , The suspending agent can also choose kaolin.

Embodiment 2

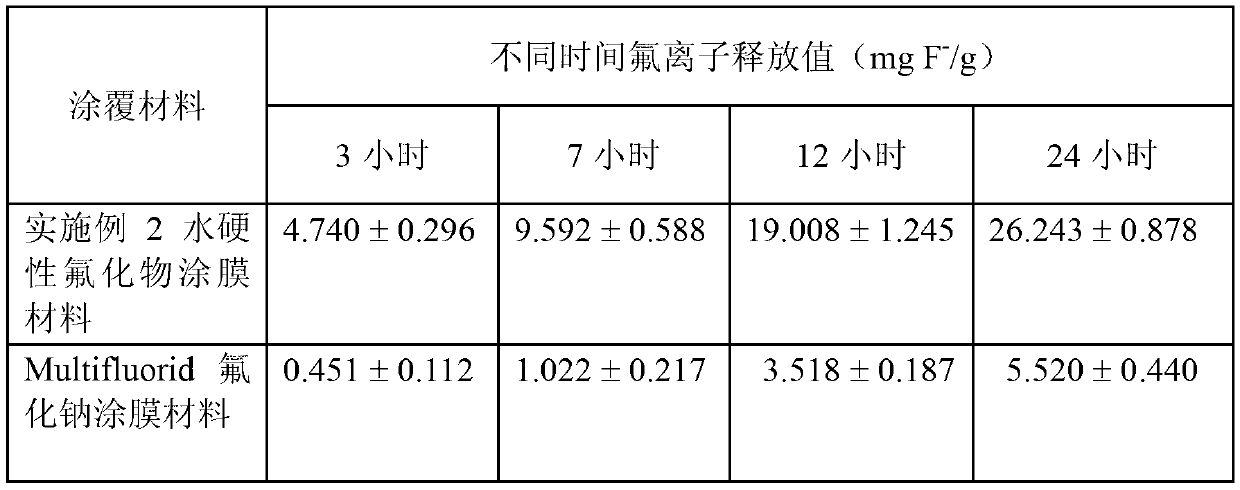

[0039] Disperse 10g of sodium fluoride with an average particle size of 10μm and 7g of colloidal silicon dioxide in 40ml of 96% ethanol solution through an ultrasonic disperser, then add 155g of shellac, fully dissolve, add 3g of octadecyl phosphate, and then add 2g of saccharin, 1g of strawberry essence, stirring and dispersing for 3 hours until all ingredients are completely dissolved, and then a fluoride coating film material with a sodium fluoride content of 5mg / ml, a film-forming material content of 70%, and an adhesion promoter content of 30% is obtained . Copal resin can also be used as the film-forming material, stearyl phosphate as the film-forming accelerator, and kaolin clay as the suspending agent.

Embodiment 3

[0041] Disperse 6g of sodium fluoride powder with an average particle size of 3.0μm and 1g of colloidal silicon dioxide in 130ml of 96% ethanol solution through an ultrasonic disperser, then add 60g of shellac, and after fully dissolving, add 3.1g of octadecyl phosphate , then add 2g of saccharin and 1g of strawberry essence, and continue to stir and disperse for 3 hours until all the ingredients are completely dissolved to obtain a fluoride coating with a sodium fluoride content of 5mg / ml, a solvent content of 60%, and an adhesion promoter content of 1.5%. Material. The film-forming material can also be selected from polymerized rosin or Kepa resin, the film-forming accelerator can also be selected from octadecyl phosphate, and the suspending agent can also be selected from kaolin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com