Method for in-situ synthesis of SiC nanowires modified carbon/carbon composite preform by sol-gel method

A technology of sol-gel method and carbon composite materials, which is applied in the field of in-situ synthesis of SiC nanowire modified carbon/carbon composite material preforms by sol-gel method, which can solve the problems of carbon fiber damage and other problems, and achieve low cost and low decomposition temperature , Improve the effect of densification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

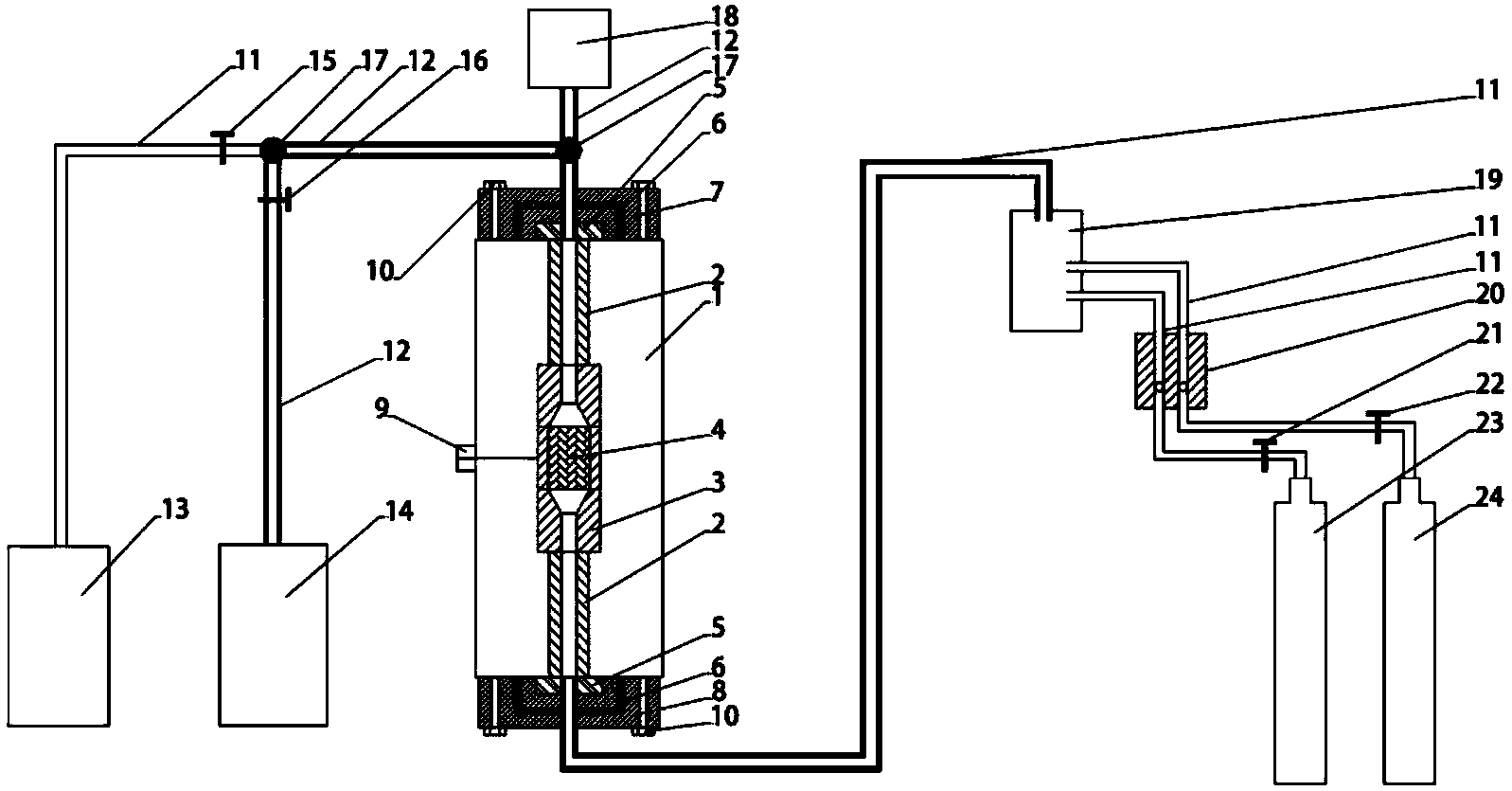

[0051] figure 1 As shown, the schematic diagram of the CVI deposition SiC nanowire modified carbon / carbon composite material prefabricated device, the position and connection relationship of each part are correct, the ratio is according to the amount, and the operation is performed in sequence.

[0052] In the furnace body 1, there are graphite gas pipes 2 and graphite molds 3 for deposition, carbon felt-silica gel 4 in the graphite mold, sealing rings 5 and circulating water 6 for cooling at the upper and lower ends of the furnace body, and the furnace body The upper cover 7 and the lower cover 8 of the furnace body are hermetically connected with the furnace body through sealing bolts 10 . There is a thermocouple 9 in the constant temperature zone where the sample is placed in the middle of the furnace body to test the reaction temperature of the furnace body. The gas outlet of the furnace body is connected to the gas pipe 11, the vacuum gauge 18, and the vacuum pipe 12 t...

Embodiment 1

[0057] (1) 2D carbon felt (density about 0.3-0.4g / cm 3 ) cutting, shearing and grinding into regular and flat samples of 70×50×10 mm in size, and then placed in an oven and dried at 60°C for 10 hours for later use.

[0058] (2) Weigh 41.6 g of tetraethyl orthosilicate (TEOS) and place it in a beaker, add 19.2 g of absolute ethanol (ETOH) into the beaker, add a magnetic rotor and stir on a magnetic stirrer for 30 minutes, then add 7.2 g of deionized water g, continue magnetic stirring for 30 min. While stirring continuously, add hydrochloric acid solution dropwise to adjust the pH value to between 2.5-3.

[0059] (3) Cover the beaker with a plastic wrap, then place the solution in an oil bath stirring device and stir at 70° C. for 2 h. Then put it in an oven at 60°C to dry and gel for 24 hours, and use it as a sol impregnation solution for later use.

[0060] (4) Place the prepared carbon felt sample in the above-mentioned sol impregnation solution, and impregnate for 72 hou...

Embodiment 2

[0067] (1) 2D carbon felt (density about 0.3-0.4g / cm 3 ) cutting, shearing and grinding into regular and flat samples of 70×50×10 mm in size, and then placed in an oven and dried at 60°C for 10 hours for later use.

[0068] (2) Weigh 41.6g of tetraethyl orthosilicate (TEOS) and place it in a beaker, then add 19.2g of absolute ethanol (ETOH) into the beaker, add a magnetic rotor and stir on a magnetic stirrer for 30min, then add deionized water 7.2g, continue magnetic stirring for 30min. While stirring continuously, add hydrochloric acid solution dropwise to adjust the pH value to between 2.5-3.

[0069] (3) Cover the beaker with a plastic wrap, then place the solution in an oil bath stirring device and stir at 70° C. for 2 h. Then put it in an oven at 60°C to dry and gel for 24 hours, and use it as a sol impregnation solution for later use.

[0070] (4) Place the prepared carbon felt sample in the above-mentioned sol impregnation solution, and impregnate for 72 hours by soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com