Process for performing sulfide ore flotation by using liquid carbon dioxide

A technology of liquid carbon dioxide and sulfide ore, applied in the field of comprehensive utilization of resources, can solve problems such as insufficient flotation time, troublesome maintenance of flotation columns, uneven mineralization, etc., and achieve high mineralization effect, not easy to block, and uniform bubble dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

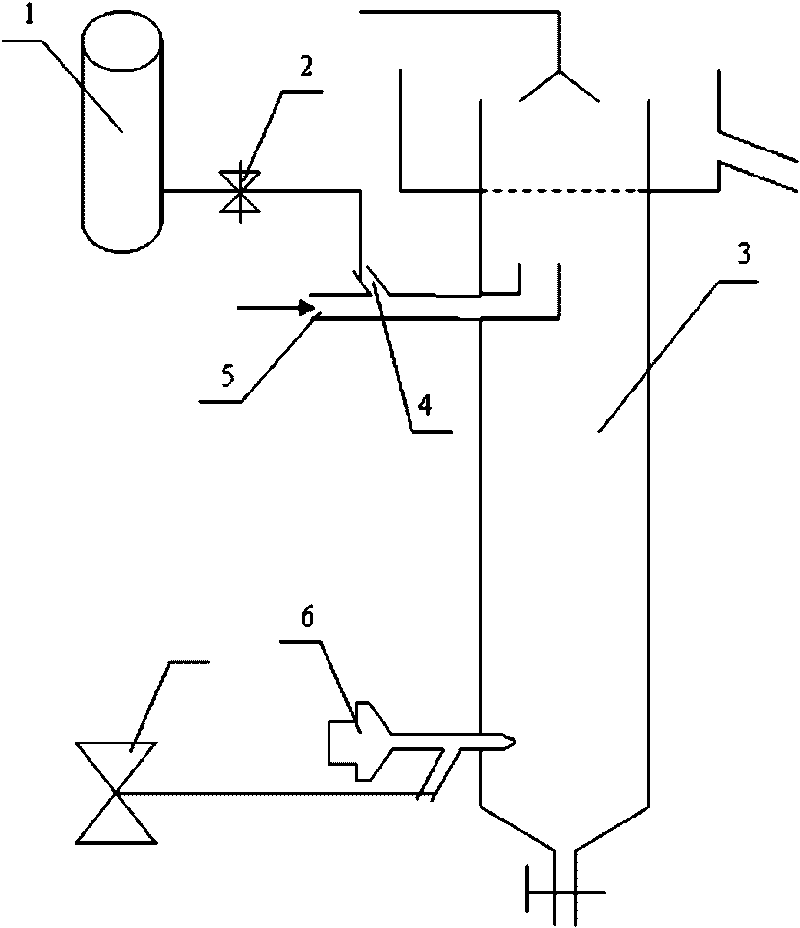

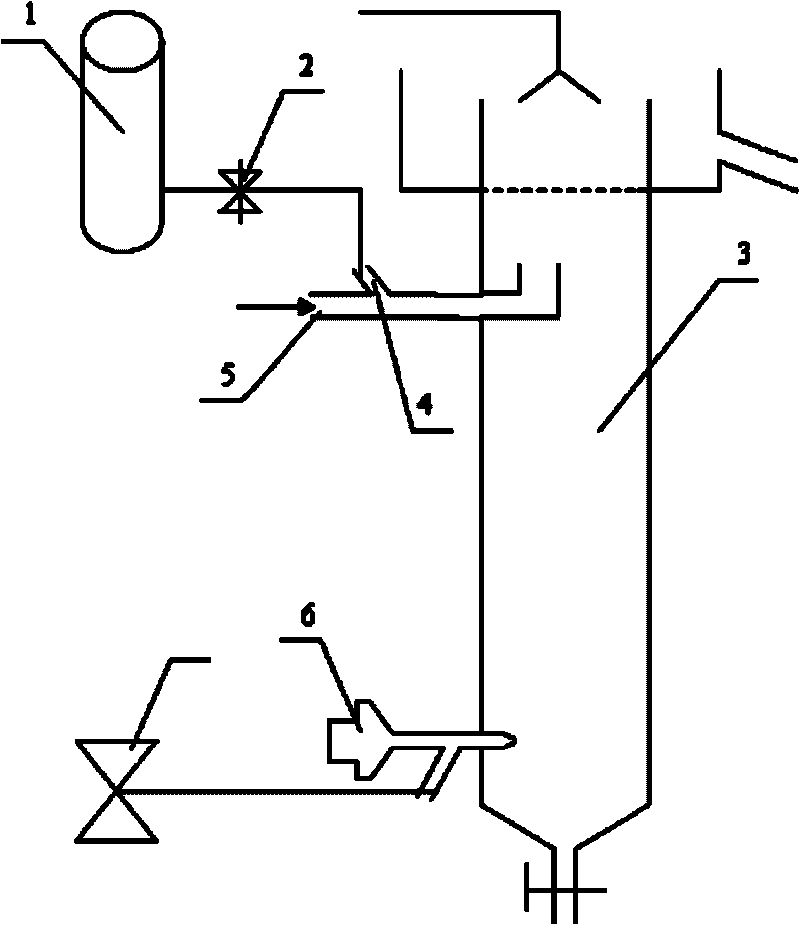

[0012] see figure 1 , the liquid carbon dioxide 1 is passed into the flotation column 3 through the pressure reducing valve 2 through the air inlet 4 together with the flotation pulp entering through the feed port 5, the liquid carbon dioxide 1 is vaporized, and bubbles grow on the surface of the hydrophobic ore particles, The air bubbles generated in the flotation column 3 and the magnetic air bubble generator 6 are reversely collided to realize sulfide ore flotation.

[0013] Using the method of the present invention, a sulfur separation test was carried out on a certain sulfide ore in Hunan. The sulfide ore is tailings after lead-zinc flotation, the main minerals are pyrite, including pyrite, pyrrhotite, etc., and the gangue minerals are mainly carbonate and silicate minerals. During flotation, the mass concentration of ore pulp is 32-34%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com