Pipe flow section device applicable to mineralized fine grain minerals

A mineral and pipe flow technology, applied in the direction of cyclone device, solid separation, flotation, etc., can solve the problems of fine mineral particle loss, increase equipment cost, increase the length of pipe flow section, etc., achieve enhanced mineralization effect and improve recovery Efficiency, the effect of increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

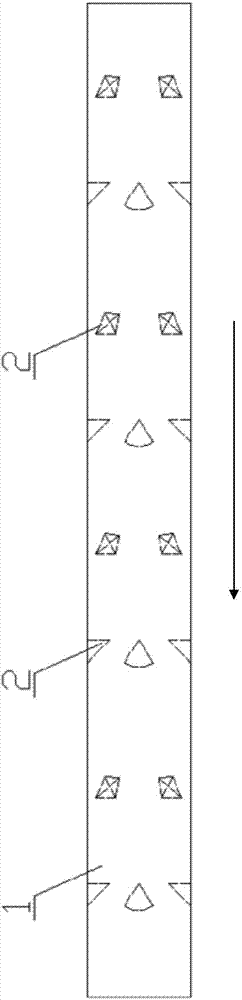

[0020] The present invention will be further described below in conjunction with accompanying drawing. figure 1 The arrows in represent the flow direction.

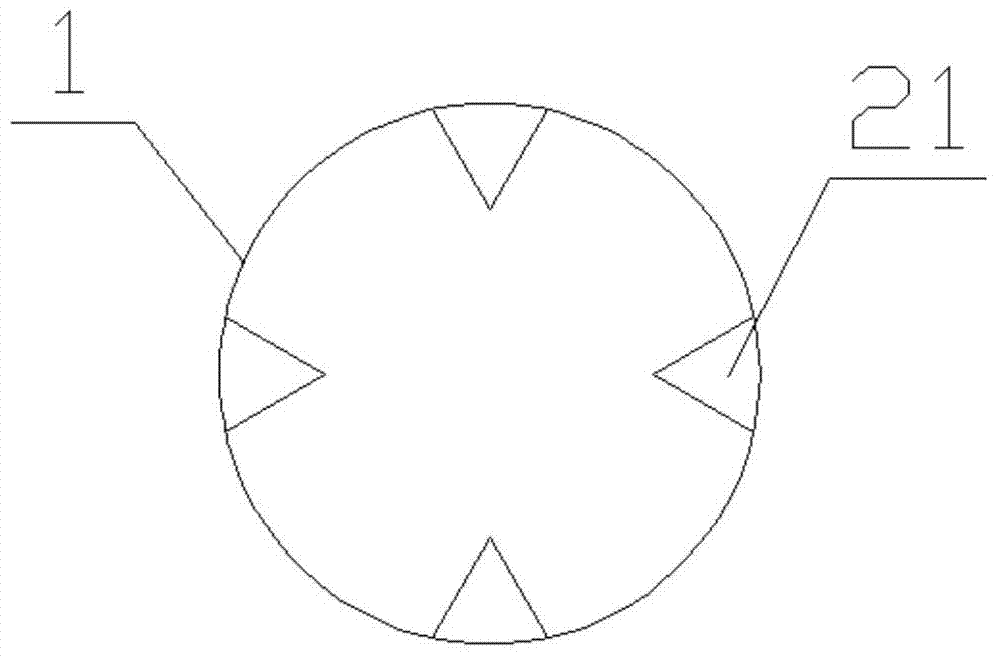

[0021] like Figure 1 to Figure 2 As shown, the pipeline 1 comprising the bubble generator downstream of the flotation column to the inlet end of the swirl section is provided with at least one row of vortex generators 2 on the inner wall of the pipeline 1 along the axis of the pipeline, and the vortex generators It is several protrusions 21 surrounding the inner pipe wall of the pipeline.

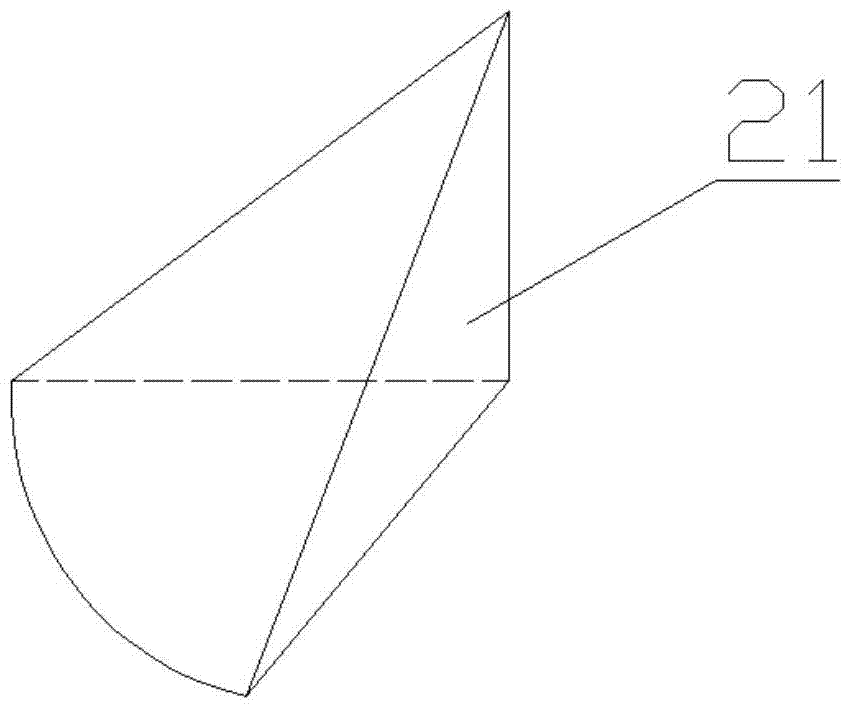

[0022] The preferred solution is as image 3 As shown, the protrusion 21 has a tetrahedral structure, and the surface of the tetrahedron connected with the inner pipe wall of the pipeline 1 is the bottom surface.

[0023] Further, the ratio of the height between the vertices of the tetrahedron and the bottom surface to the inner diameter of the pipeline 1 is 0.15˜0.3.

[0024] Furthermore, the bottom of the tetrahedron is an isosc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com