Method for preparing chitosan oligosaccharide modified biodegradable composite

A technology of biodegradation and composite materials, which is applied in the field of preparation of biodegradable composite materials, can solve the problems of chitosan oligosaccharides being incapable of melting, poor compatibility, etc., to improve molding performance, reduce crystallinity, and have broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] ① Preparation of polycaprolactone (PCL)

[0045] After the three-necked flask was blown with nitrogen to remove impurities such as moisture and oxygen in the flask, ε-caprolactone was added, stannous octoate was put into dry pyridine to prepare a pyridine solution with a mass concentration of 20%, and under nitrogen protection, the Add 20% pyridine solution dropwise to the above-mentioned three-necked flask, stir and react in an oil bath at 120°C for 26 hours, then stop the reaction; precipitate the reacted product with methanol, and dry the white powder in vacuum at 40°C to obtain desired polycaprolactone;

[0046] ②Chitooligosaccharide grafted polycaprolactone thermoplastic material and polycaprolactone blend membrane preparation

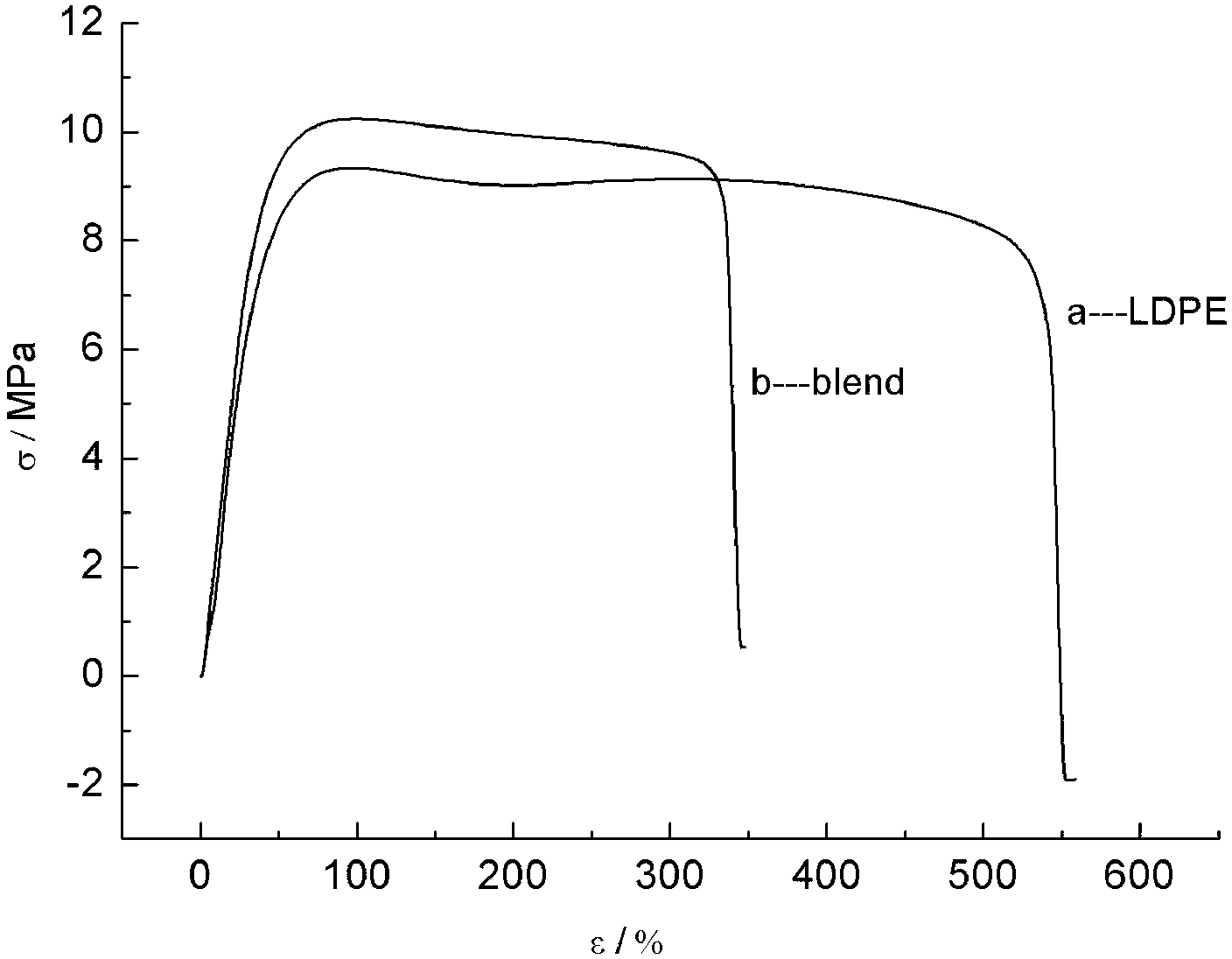

[0047] Dry the purchased industrial low-density polyethylene (LDPE) at 100°C for more than 6 hours in a blast dryer, PHCSO-g-PCL (chitooligosaccharide grafted polycaprolactone thermoplastic material obtained in step (1)) and PCL (The poly...

Embodiment 1

[0059] 1. Preparation of chitooligosaccharide grafted polycaprolactone thermoplastic material

[0060] (1) Preparation of N-phthalylated chitooligosaccharides

[0061] The chitosan oligosaccharide purchased was dried in a vacuum oven for 48 hours to remove the adsorbed water on its surface, and then stored in a desiccator for subsequent use.

[0062] Add 1g of chitosan oligosaccharide, 2g of phthalic anhydride and 30ml of N, N-dimethylformamide into a three-necked flask in sequence, and react for 7 hours in an oil bath at 90°C, then pour the reaction solution into ice water for sedimentation , the precipitate was repeatedly washed with ethanol for 3 times and acetone for 3 times, filtered, and then placed in a 45°C oven to dry to constant weight to obtain a brown powder product N-phthalylated chitooligosaccharide reaction intermediate body with a yield of 67.85%.

[0063] (2) Preparation of N-phthalylated chitooligosaccharide grafted polycaprolactone

[0064] Dissolve the ...

Embodiment 2

[0076] 1. Preparation of chitosan oligosaccharide grafted polycaprolactone thermoplastic material, the molar ratio of stannous octoate to ε-caprolactone monomer in step (1) is 1%, N-phthalylated chitosan oligosaccharide and ε -The proportioning ratio of caprolactone is 1: 15 (g / mL), and all the other conditions are the same as in Example 1;

[0077] 2. Preparation of Chitooligosaccharide Modified Biodegradable Composite Materials

[0078] ① Preparation of polycaprolactone (PCL) (the molar ratio of stannous octoate to ε-caprolactone monomer is 0.05%, and the preparation conditions are the same as in Example 1).

[0079] ②Chitooligosaccharide grafted polycaprolactone thermoplastic material and polycaprolactone blend membrane preparation

[0080] LDPE was dried in a blast dryer at 100°C for more than 6 hours, and PHCSO-g-PCL and PCL were dried in a vacuum oven at 50°C for more than 6 hours.

[0081] Accurately weigh 4g chitosan oligosaccharide grafted polycaprolactone thermop...

PUM

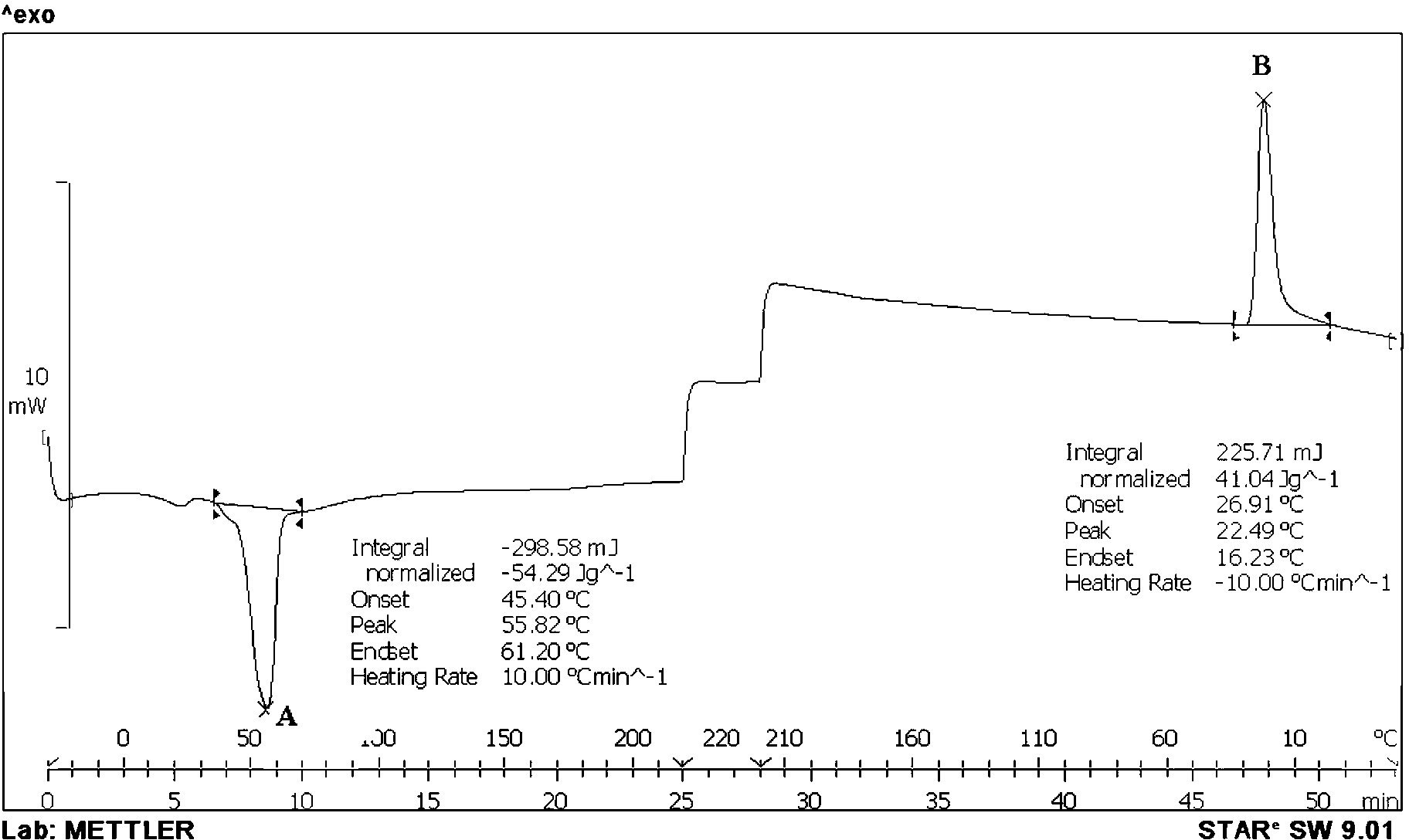

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com