Production method of high strength and environmental-friendly textilene

A production method and environment-friendly technology, applied in filament/thread forming, textile and papermaking, fiber treatment, etc., can solve the problems of poor environmental performance and achieve long service life, high mechanical strength, bright colors and non-fading effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

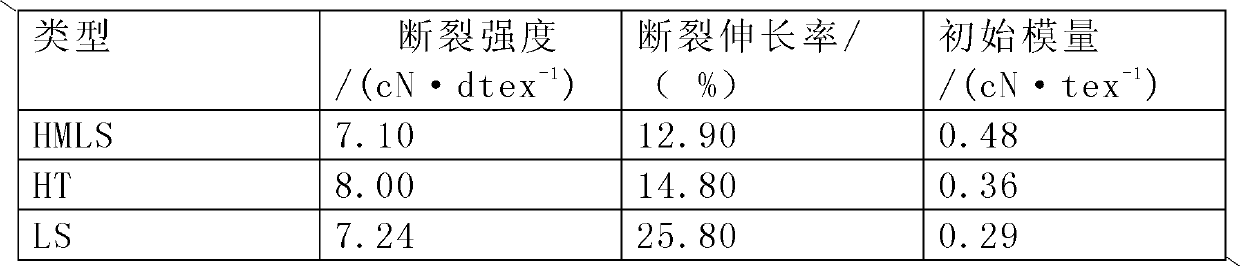

Embodiment 1

[0023] Put the PE / PP copolymer masterbatch of the same color into the feed port of the plastic extruder, and the PE / PP copolymer masterbatch is plasticized into a uniform melt through the extrusion system of the plastic extruder, and is extruded by the plastic The pressure built up in this process is continuously extruded by the screw; the HT type polyester industrial filament is passed through the plastic extruder head, and the above-mentioned extruded melt is extruded and coated on the HT Type polyester industrial filament surface, and then after cooling down from the cooling water tank, it is formed into Teslin filament containing 150D-1500D polyester industrial filament core wire, and the cortex is PE / PP copolymerized plastic; the brown and Black Teslin filaments are twisted together by a twisting machine to form Teslin skeins.

[0024] The Teslin skeins made above are processed into weaving beams one by one by a section warping machine (this method is similar to the produ...

Embodiment 2

[0026] The polyester industrial filament that adopts is the HMLS type polyester industrial filament, and the red and yellow Textilen filament that will produce are twisted together to form Textilen skein by the twisting machine, and other technical processes are the same as embodiment 1, no longer repeat.

Embodiment 3

[0028] The polyester industrial filament that adopts is the LS type polyester industrial filament, and the green and brown Textilen filament that will produce are twisted together to form Textilen skein by the twisting machine, and other technological processes are the same as embodiment 1, no longer repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com