Novel breather hole EVA (Ethylene Vinyl Acetate) foamable material for automobile seat cushion and preparation method of novel breather hole EVA foamable material

A technology of foaming materials and air holes, applied in the field of foaming materials, can solve the problems of insufficient comfort, easy cracking, poor air permeability, etc., and achieve the effect of excellent softness and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

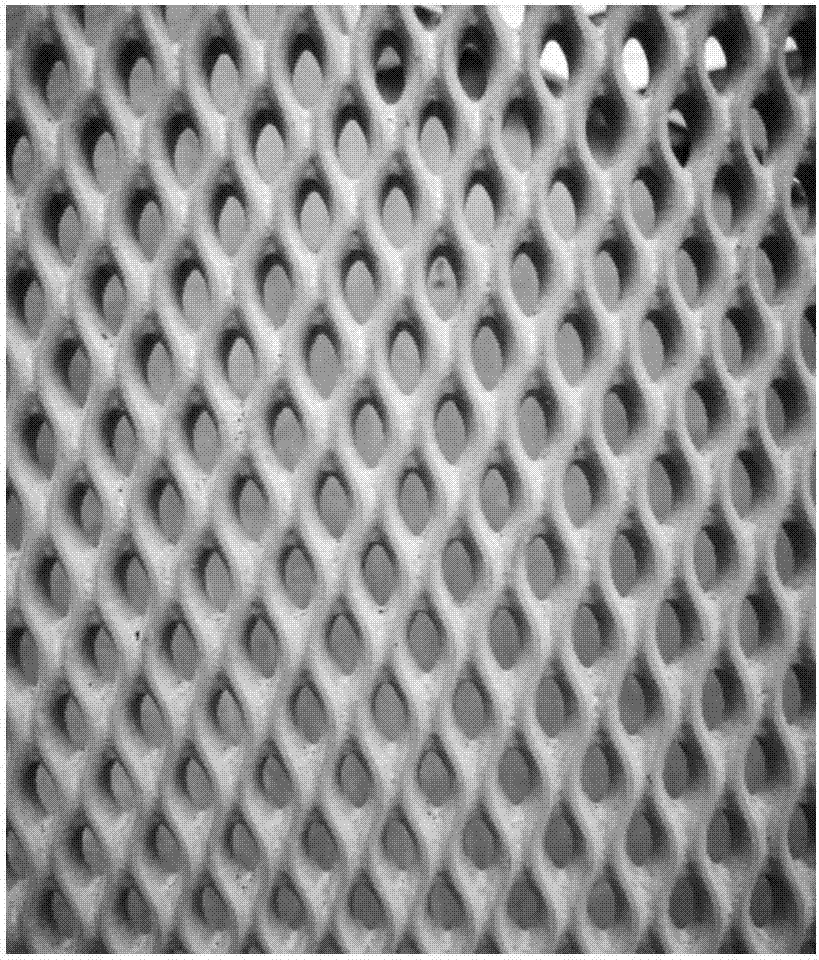

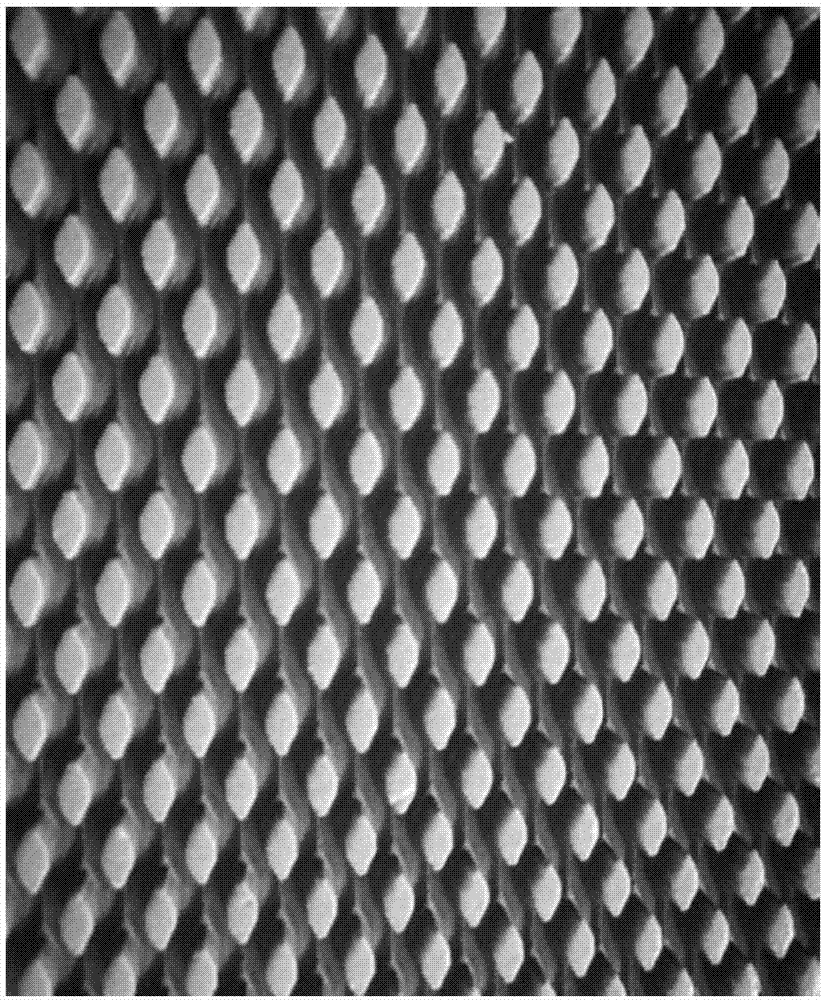

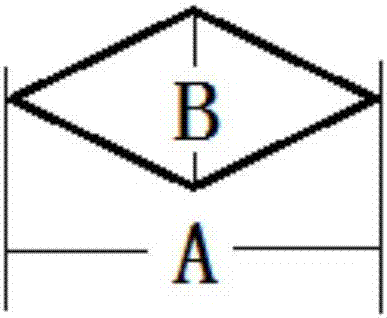

[0027] A new air-vent EVA foam material for car seat cushions, specifically a hollow-shaped air-hole structure, the hollow-shaped air-hole structure is a plurality of diamond-shaped air-holes evenly distributed, and the long-diagonal length of the diamond-shaped air-holes 6mm, short diagonal length 3mm; including the following preparation raw materials calculated by weight: ethylene-vinyl acetate copolymer EVA 20Phr, recycled low-density high-pressure polyethylene LDPE 15Phr, POE 15Phr, foaming agent 4.0Phr, zinc oxide 3.0 Phr, stearic acid 1.0Phr, peroxide crosslinking agent 1.0Phr, heavy calcium carbonate 20Phr, pigment 1.0Phr, the mesh number of the heavy calcium carbonate is more than 1000 mesh; the ethylene-vinyl acetate copolymer EVA The grade 18J3 produced by Yanshan Petrochemical, the acetic acid content is 18%, the POE is Dow POE, grade 8150; the regenerated low-density high-pressure polyethylene LDPE is LDPE produced by Shanghai Petrochemical, the grade is N150; the f...

Embodiment 2- Embodiment 5

[0029] Concrete preparation raw material ratio is as shown in Table 1, and all the other are identical with embodiment 1.

[0030] Table 1 embodiment 2-5 prepares raw material formula unit Phr

[0031]

[0032]

[0033] Remarks: Among them, heavy calcium is the abbreviation of heavy calcium carbonate, and DCP is the peroxide crosslinking agent.

Embodiment 6

[0035] Take the proportioning of embodiment 3, the preparation of the novel air-permeable EVA foaming material of automobile seat cushion, comprises the steps:

[0036] (1) Weighing: Accurately weigh the required raw materials according to the ratio of the formula with an electronic balance, and the error is less than 1g;

[0037] (2) Internal mixing: Pour the weighed raw materials into the internal mixer, stir evenly without pressing the weight into the internal mixer, and then carry out the mixing process. The cooling water temperature in the internal mixer is controlled below 70°C, and the compression When the air pressure is 0.7-0.9MPa and the material temperature is 105-115℃, the material is discharged;

[0038] (3) Open milling: send the material discharged from the internal mixer into the open mill for open milling. The temperature of the front roll is 80-90°C, the temperature of the rear roll is 70-80°C, and the roll distance is 0.3-0.7mm. 3-5 times;

[0039] (4) Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com