Latex thread separation guide adjusting device and method

A technology of guide adjustment and guide device, which is applied in the direction of filament production, textiles and papermaking, etc., and can solve the problems of lower qualified rate of latex yarn, restricting the development of latex yarn, and failure to prevent sticking of latex yarn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

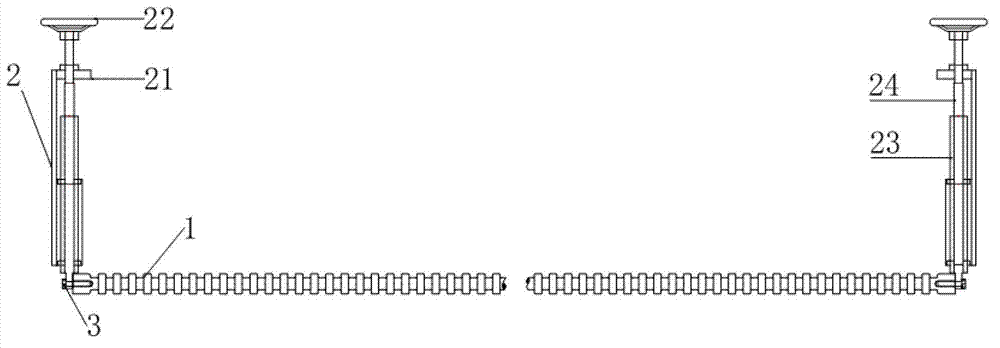

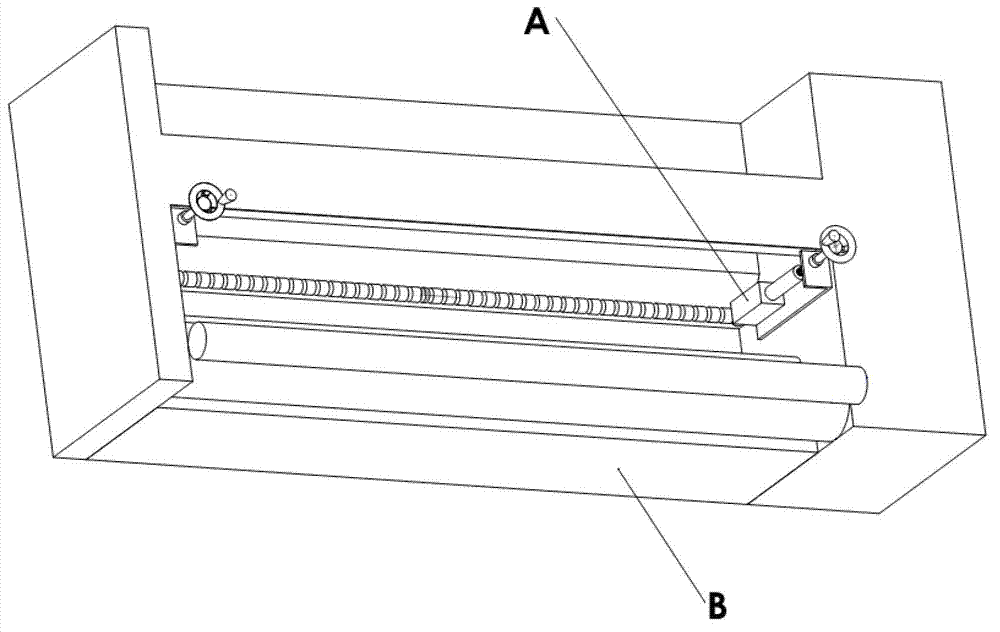

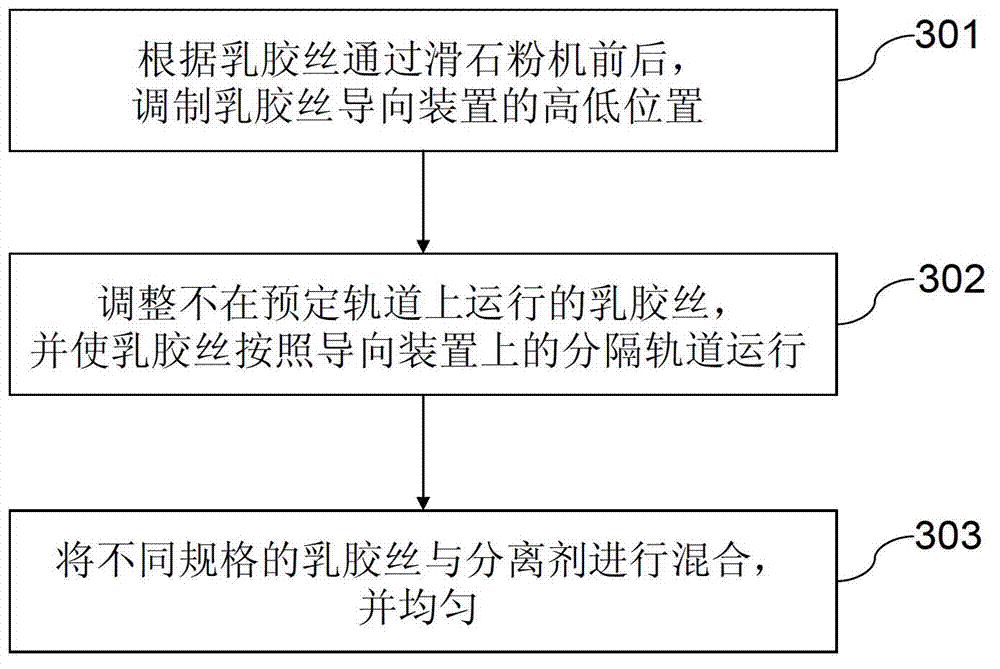

[0019] see figure 1 , is the structure of the latex wire separating guide adjustment device, including a guide separation mechanism 1 and an adjustment mechanism 2, and the guide separation mechanism is connected with the adjustment structure;

[0020] The adjustment mechanism is used to adjust the height position of the latex wire separation guide adjustment mechanism and the control of start and stop.

[0021] Described guiding separation mechanism is made up of the separating groove on connecting rod and connecting rod; Adjusting mechanism comprises fixed mount 21, hand wheel 22, screw sleeve 23 and screw rod 24, and described hand wheel is fixed on an end of screw rod; Described screw sleeve and The other end of the screw is connected....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com