Ultrahigh molecular weight polyethylene lining composite pipe production method and device

A technology of ultra-high molecular weight polyethylene pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., which can solve problems affecting product quality and efficiency, waste of manpower and financial resources, and short service life of oil pipes, etc., to improve Production quality and production efficiency, high work efficiency, and the effect of shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

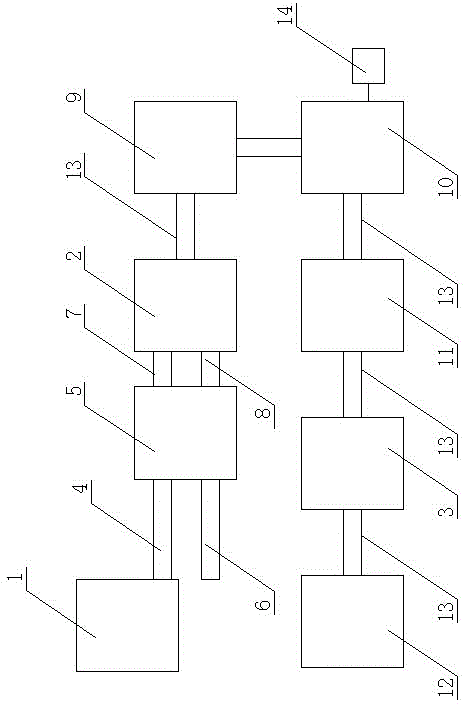

Image

Examples

Embodiment 1

[0018] The production method of the ultra-high molecular weight polyethylene lined composite pipe of the present invention is realized through the following steps:

[0019] a. Pretreatment: dust and clean the composite steel pipe, and remove the protective buckles at both ends;

[0020] b. Material selection: select an ultra-high molecular weight polyethylene pipe with a diameter of 3-9mm larger than the inner diameter of the steel pipe in step a, and shrink the diameter to 1 to 2mm less than the inner diameter of the steel pipe;

[0021] c. Compound: Put the ultra-high molecular weight polyethylene pipe obtained in step b into the steel pipe of step a immediately;

[0022] d. Stress relief: Put the composite pipe obtained in step c for 22 to 26 hours to recover the stress, the polyethylene pipe rebounds and closely adheres to the inner wall of the steel pipe, and the temperature is 70°C to 90°C for 1.5 to 3 hours to remove the stress and form the composite. complete;

[0023] e. Cut-t...

Embodiment 2

[0026] The production method of the ultra-high molecular weight polyethylene lined composite pipe of the present invention is realized through the following steps:

[0027] a. Pretreatment: Dust and clean the composite steel pipe with a diameter of 60mm, and remove the protective buckles at both ends;

[0028] b. Material selection: select an ultra-high molecular weight polyethylene pipe with a diameter of 64mm, shrink the diameter to 58mm with a diameter reducing machine; then clean the reduced diameter ultra-high molecular weight polyethylene pipe; For: 64mm, 63mm, 62mm, 60mm, 59mm, 58mm;

[0029] c. Compound: Put the ultra-high molecular weight polyethylene pipe obtained in step b into the steel pipe of step a immediately;

[0030] d. Stress relief: Place the composite pipe obtained in step c for 23 hours to recover the stress, make the polyethylene pipe rebound and closely adhere to the inner wall of the steel pipe, and hold it at a temperature of 70°C to 90°C for 2 hours to remov...

Embodiment 3

[0034] The production method of the ultra-high molecular weight polyethylene lined composite pipe of the present invention is realized through the following steps:

[0035] a. Pretreatment: The 73mm diameter composite steel pipe to be compounded is cleaned with a washing machine, and the protective buckles at both ends are removed;

[0036] b. Material selection: select an ultra-high molecular weight polyethylene pipe with a diameter of 81mm, shrink the diameter to 72mm with a diameter reducing machine; then clean the reduced diameter ultra-high molecular weight polyethylene pipe; the roller size of the diameter reducing machine is in turn For: 81mm, 80mm, 78mm, 76mm, 74mm, 72mm;

[0037] c. Compounding: Put the ultra-high molecular weight polyethylene pipe obtained in step b into the steel pipe obtained in step a immediately and put it into the compound mold machine for compounding;

[0038] d. Stress relief: Put the composite pipe obtained in step c for 24 hours to recover the stres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com