Metallurgical auxiliary material core-wrapped blocks and production device thereof

A production device and core-spun technology, applied in packaging and other directions, can solve problems such as affecting the use effect and economic benefits, inability to effectively enter the metallurgical melt, limited feeding depth, etc., to achieve resource saving, compact structure, and high qualified finished products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

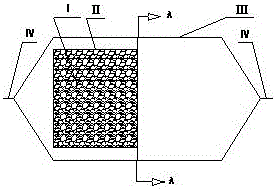

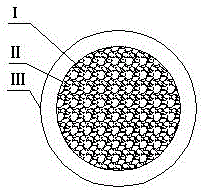

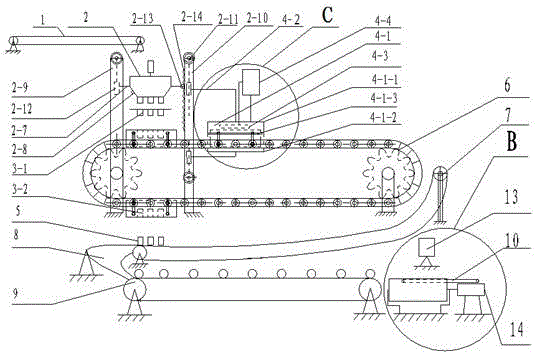

[0038] Depend on figure 1 , 2 It can be seen that the metallurgical auxiliary material cored block is composed of metallurgical auxiliary material core material, soft coating and hard foreskin, wrapped layer by layer, with pressing edges at both ends, in block shape, and the effective equivalent diameter is less than 60-350mm; The particle size of the auxiliary material is less than 50 mm; the soft coating has thermoplastic sealing performance, and the core material is vacuum-wrapped to form a soft mass, and the vacuum degree is less than or equal to 200 Pa, so as to prevent the auxiliary material from being breathable, moisture absorption, hydration, oxidation or pulverization and denaturation failure; The hard foreskin is made of a thin steel strip with a thickness of 0.03-3.0 mm, wrapping the soft mass into a hard mass, increasing the strength of the core-forming block and preventing mechanical damage to the core-forming block. When in use, it is directly put into the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com